Okay!

That is a lot of good information to work with.

Generally when diagnosing jetting, I like to start from the top (WOT) and move down to idle.

It sounds like you got WOT figured out really well.

Anything bigger than the .60 and you loose power in the top end, I can verify for you (along with the verification of your experience) that is indeed what you would expect to experience as you go "too rich".

Now, you do not have anything smaller than a .60 main, and that I would say is just fine.

If you wanted to be EXTRA sure you had the jetting right, you would start by knowing that you loose power power going bigger than .60.

THEN you would want to at least see what happens as you go SMALLER than .60.

Does it gain even more power with a .58 for example?

Or does it immediately start to loose power again as you go smaller?

This would then tell you where "most power" is found, as relating to the main jet.

Now you have to make a decision:

A. Use the jet the shows the MOST power. This will give you the best power for a single run up to WOT. So like on a race track, where you do not spend very much time "staying" at WOT (depending on gearing obviously) you could use this jetting.

B. Use the jet that is one step RICHER (or more, depending on you conditions) than the jet that shows most power. This will sacrifice some power (not much at all) on your first WOT runs, BUT, if you are running at WOT for extended periods time (example: commuting) you will not loose NEARLY as much power as the engine heats up, and you will SAFELY be able to run at WOT for extended periods of time.

Now this is a decision you have to make for yourself.

And just for some guidance, rich enough to 4-stroke JUST SLIGHTLY when you first hit WOT is a pretty good setting.

As the engine heats up while you stay at WOT, the 4-stroking should go away.

IF after being at WOT for an extended period of time at a steady RPM, all of a sudden the RPM's start to slowly rise, this is a sign of the engine being so hot, that the mix is now going to the lean side of things, and is less safe.

If you continue for enough time after this, and all of a sudden RPM's fall, even though the ground hasn't changed its level (uphill, downhill) then you are now starting to experience detonation as a result of the lean condition, and this is robbing power, and this reducing RPM's.

If you continue long enough after THIS, you will develop a hole in the crown of the piston, although the engine will CONTINUE to run, you will have a sensation like it has lost ALL LOW END TORQUE, and will ONLY RUN at high RPM's.

This is bad.

Don't do this.

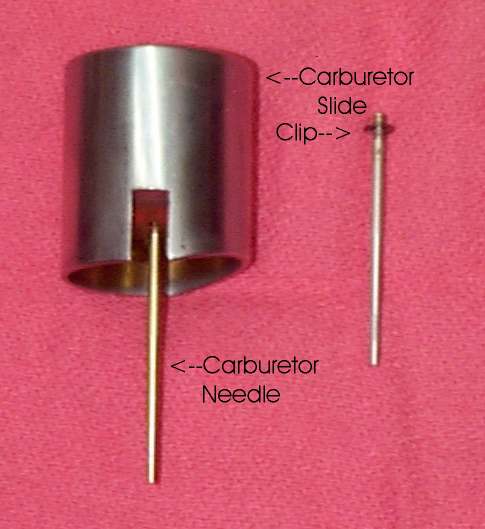

Now you said the RT carb only has one clip position....

Are you talking about this part:

And your "needle" only has one "needle slots" (also referred to as "clip positions")???

I don't think I have seen any that only have one slot... But I can't say I have seen 'em all.

BUT, not having an adjustable clip position on the needle REALLY limits your ability to tune the "mid-Range" and "off-idle" carburetor jetting.

At this point I would say you have the MAIN JET basically perfect.

NOW, about the engine REV's not wanting to fall.

I.E. you Rev the engine, and you let off the throttle, and the engine stays at HIGH RPM, and takes a full few seconds to fall (however long it takes to fall, you can hear really well with your ear when its lagging, and that is definitely what you are experiencing).

There can be two MAIN causes of this.

The first one is purely mechanical, and has nothing to do with jetting:

If the carburetor slide does not move smoothly up and down with the twist of the throttle (I.E. when you let off the throttle, the slide lags as it "pulls" the cable slack from the released throttle).

This lag in the ability of the slide to "drop" just as quickly as you let go of the throttle will be experienced as the engine lagging when the REV's fall.

If it is obviously NOT this, the slide is moving up and down butter smooth, then it likely jetting.

This condition, of the REV's not wanting to fall (when it IS IN FACT jetting) is ALWAYS due to a LEAN condition.

SO, not being able to move the clip position on the needle to one richer position (moving the clip to a "lower" position) is kind of a bummer.

BUT, there is still another option for adjusting "idle" and "off idle" mixture, and that is a tuning measurement referred to as "slide cutaway".

Here is an example:

This shows a STOCK NT Carb slide, and one that I modified (through judicious use of a hand file) to have MORE "slide cutaway".

Unfortunately for YOU, MORE SLIDE CUTAWAY makes "idle" and "off-idle" LEANER.

...exactly what you don't want.

And the STOCK Slide has VERY LOW "slide cutaway" to begin with, and is USUALLY TOO RICH.

SO, this leads me to think that the "clip position" on the "needle" in your carburetor is in a position that is "TOO LEAN" (meaning the clip is TOO HIGH on the needle, and its position needs to be LOWERED).

If after further examination of your carburetor, you find that your "needle" does in fact have multiple positions for placing the "clip", I would recommend "lowering" the clip position.

Because of how the needle is assembled into the slide, as you "lower" the clip position, you "raise" the needle, so that it is "higher". This means it will allow MORE FUEL past its "tip" witch goes down into the "fuel chamber". This is why "lowering" the "clip position", and thus "raising" the "needle" has the effect of making the mixture richer.

The Needle Position in the carburetor has the MOST effect from 1/8 throttle opening, to 3/4 throttle opening. It also has a slight effect lower and higher than this.

This "slide "cutaway" in this carburetor has the MOST effect from 0 Throttle opening to 1/4 throttle opening. It also has a slight effect higher than this.

The MAIN JET in this carburetor has the MOST effect from 1/2 throttle opening to WOT. It also has a slight effect lower than this.

Let me know if you need anymore guidance after you digest all of that