You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jackshaft

- Thread starter CraftsmanJB

- Start date

CraftsmanJB

New Member

Thank you for the reply , to both responders .. I'm confused on the pillow bearings... never heard of them ... I'm just inquiring about it not sure I actually want a jackshaft .. I'm still in the process of adding all the final details . Motor is built to the hill , and still fresh .. I have more graphics airbrush on the way as well ... always something new on the market to buy .. lol come Springs it'll be finished and ready to cruise an enjoy .. I have saddlebags to match for cruising . Now to run at top speeds in traffic, saddlebags will stay home .. just now getting my chrome racing expansion chamber cut to fit .

Thanks again for the compliments

Thanks again for the compliments

Attachments

Last edited:

ragdolldude

Member

Sick bikes have a jackshaft kit, but not for 1 1/2" downtube. Guess you could grind the mount out a little and get some larger clamps from a mufler store to hold it in place?

CraftsmanJB

New Member

What's the typical block pillow bearings ID size for motorized bicycles ? Shaft size ?

How do you calculate the sprocket size / teeth ?

Thank You Brother for your help and advice

I could definitely use the cnc motor mounts for this application, so much clearance

How do you calculate the sprocket size / teeth ?

Thank You Brother for your help and advice

I could definitely use the cnc motor mounts for this application, so much clearance

ragdolldude

Member

I used pillow blocks that I got from local hardware stores in the 60's. One set on a DIY gokart and another set on a mini bike with a home made frame, and an old Schwinn springer front end. 1/2 and 5/8 inch shafts were locally available at local small hardware stores in southern CA.

MotoMagz

Well-Known Member

Thanks SBest nice pictures! The only thing I would add is if you use muffler claps as your U bracket put the metal clamp from the muffler clamp between seatpost and plat. This way plate is resting against a flat service not a round seatpost. It will keep it from slipping..

TheNecromancer13

Active Member

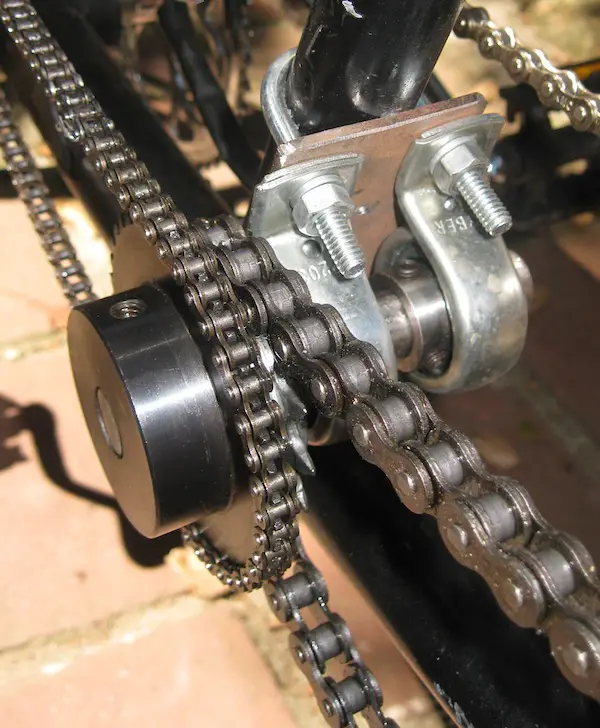

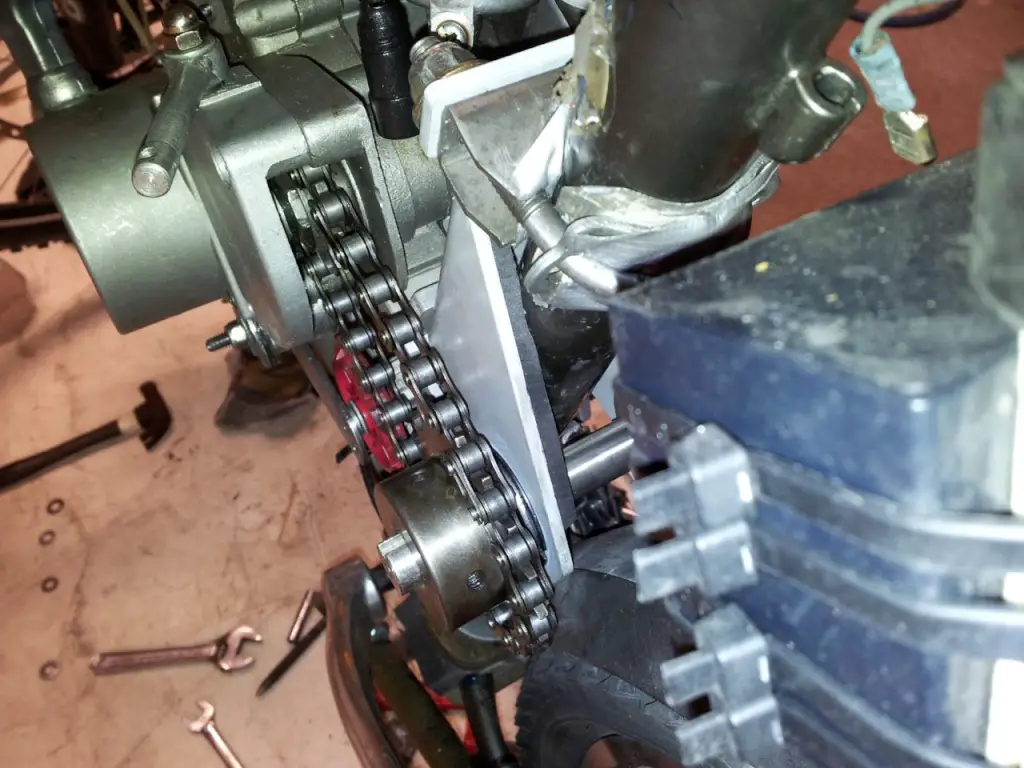

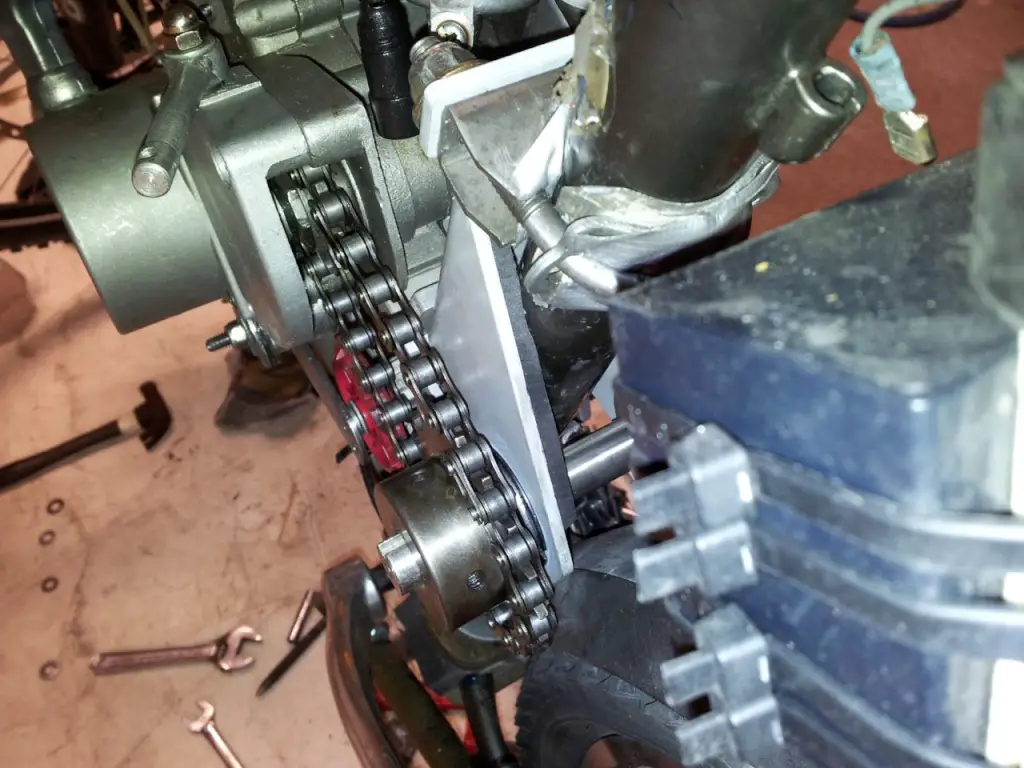

Here's some pics of my lifan bike's jackshaft, which uses pillow block bearings:

The bare threads on the bike's right side are for a freewheel to connect the pedals that I haven't added yet.

The bare threads on the bike's right side are for a freewheel to connect the pedals that I haven't added yet.

sbest

Member

>What's the typical block pillow bearings ID size for motorized bicycles ? Shaft size ? <

Typically 5/8" shafting is used.

I see no reason why 1/2" couldn't be used, lighter but a bit less common.

The common size for single speed bike chain is 410. It is plenty strong for this.

>How do you calculate the sprocket size / teeth ? <

I don't really know your aplication, but if you are just shifting the drive over to the left side to drive off of the small rear wheel sprocket you would want to keep the same 10t/44t ratio (for example). So if your rear sprocket is a 16t you will need a 12/33 ratio on your jackshaft to keep that original 10/44 ratio. Keep in mind you will not be able to bump start if you run through the freewheel in the back.

Sprockets are not usually available much smaller than 9 teeth. Small sprockets wear chain faster so we usually size over 11 teeth if we can.

From Motomags>>The only thing I would add is if you use muffler claps as your U bracket put the metal clamp from the muffler clamp between seatpost and plat. This way plate is resting against a flat service not a round seatpost. It will keep it from slipping..<<

Absolutely true. I apologize, that was a picture I grabbed off the web to illustrate a jackshaft on a bike seatpost application. Always best to clamp round thin tube in a supported fashion. CNC (or custom machined) made clamps would be even better.

Typically 5/8" shafting is used.

I see no reason why 1/2" couldn't be used, lighter but a bit less common.

The common size for single speed bike chain is 410. It is plenty strong for this.

>How do you calculate the sprocket size / teeth ? <

I don't really know your aplication, but if you are just shifting the drive over to the left side to drive off of the small rear wheel sprocket you would want to keep the same 10t/44t ratio (for example). So if your rear sprocket is a 16t you will need a 12/33 ratio on your jackshaft to keep that original 10/44 ratio. Keep in mind you will not be able to bump start if you run through the freewheel in the back.

Sprockets are not usually available much smaller than 9 teeth. Small sprockets wear chain faster so we usually size over 11 teeth if we can.

From Motomags>>The only thing I would add is if you use muffler claps as your U bracket put the metal clamp from the muffler clamp between seatpost and plat. This way plate is resting against a flat service not a round seatpost. It will keep it from slipping..<<

Absolutely true. I apologize, that was a picture I grabbed off the web to illustrate a jackshaft on a bike seatpost application. Always best to clamp round thin tube in a supported fashion. CNC (or custom machined) made clamps would be even better.

Last edited:

CraftsmanJB

New Member

Wow , looks like a lot going on there .. is that a Micargi Puma ? I'm confused about you saying to use the seat post as the mount for the plates . The plates that accommodate the pillow bearings ? Are those pillow bearings encased with any type of mounting structure ?

I like the photos , but yet still trying to place this concept on my Micargi .... any drilling through the bottom frame tube ? Or as you said I'd it all mounted to the seat post? Now what type of bearings and tpi .. how many teeth per bearing , cause y3s my motorized is built to the hill , I don't need to ride 60mph , just a reliablexpansion set up .. on the left you have a large sprocket , I take it that's the real gearing for your application.. it looks as you have a huge dirt bike engine ? First and foremost I NEED TO GET A PEDAL CRANK SET AS WIDE AS POSSIBLE , my exhaust exhaust expansion chamber is certainly in the way on the right side .. any manufacturer or dealer on ebay that might have a extra wide crank set you could advise me too ?

Anyway thanks for the details . I'm studying your pillow bearing set up , I hope I can design and pull one off .. let me know anyone about the extra wide crank please and thank you all for the support

I like the photos , but yet still trying to place this concept on my Micargi .... any drilling through the bottom frame tube ? Or as you said I'd it all mounted to the seat post? Now what type of bearings and tpi .. how many teeth per bearing , cause y3s my motorized is built to the hill , I don't need to ride 60mph , just a reliablexpansion set up .. on the left you have a large sprocket , I take it that's the real gearing for your application.. it looks as you have a huge dirt bike engine ? First and foremost I NEED TO GET A PEDAL CRANK SET AS WIDE AS POSSIBLE , my exhaust exhaust expansion chamber is certainly in the way on the right side .. any manufacturer or dealer on ebay that might have a extra wide crank set you could advise me too ?

Anyway thanks for the details . I'm studying your pillow bearing set up , I hope I can design and pull one off .. let me know anyone about the extra wide crank please and thank you all for the support

CraftsmanJB

New Member

What's the way to get ahold of Sick Bikes ? Ebay or a website?

CraftsmanJB

New Member

ragdolldude does Sick Bikes have an eBay Store or a website I could look up their jackshafts? Thank You

sbest

Member

I illustrated a seatpost mount, which is prone to twist if not clamped securely. Necromancer's bottom mounted plate is another good secure and stable option. I'd suggest a single plate under the pillow blocks, and it could be made out of 1/4" aluminum for less weight. It would still be clamped to the frame tubes with "U" bolts or two draw clamps like kickstands use.

No need of any cover over the pillow bearings, they just mount to the plate, but you might consider chain guards.

Do not drill into any bicycle frame tube. It will weaken the frame.

By the quality of your work I'd guess you know this sort of stuff, but thought I'd mention it for others that might not.

I am in Canada so shipping is a problem from many US sites.

I have ordered from Ebay and individual sellers websites with great luck.

Ebay and Paypal offer some guarantees, worth and extra $5 in my book.

Pedal sets come in differing widths, the wider ones make for cornering issues.

I like the cartridge type pedal sets:

Better than the bearing types:

And certainly better than the single arm types:

40mph can be done with a stock pipe with minor engine porting and a head, allowing use of a stock or slightly wider pedal set. With a single speed it is hard to go much faster and still have good slow speed performance.

The Sick Bike Parts jackshaft kit used side plates and flanged 5/8" bearings and clamps to the seatpost and/or motor mount. You can build a similar system but it would require more fabrication skills than pillow blocks.

No need of any cover over the pillow bearings, they just mount to the plate, but you might consider chain guards.

Do not drill into any bicycle frame tube. It will weaken the frame.

By the quality of your work I'd guess you know this sort of stuff, but thought I'd mention it for others that might not.

I am in Canada so shipping is a problem from many US sites.

I have ordered from Ebay and individual sellers websites with great luck.

Ebay and Paypal offer some guarantees, worth and extra $5 in my book.

Pedal sets come in differing widths, the wider ones make for cornering issues.

I like the cartridge type pedal sets:

Better than the bearing types:

And certainly better than the single arm types:

40mph can be done with a stock pipe with minor engine porting and a head, allowing use of a stock or slightly wider pedal set. With a single speed it is hard to go much faster and still have good slow speed performance.

The Sick Bike Parts jackshaft kit used side plates and flanged 5/8" bearings and clamps to the seatpost and/or motor mount. You can build a similar system but it would require more fabrication skills than pillow blocks.

What's the way to get ahold of Sick Bikes ? Ebay or a website?

Look at the top of this page, right-hand side. Sick is one of this forum's sponsors.

Wow , looks like a lot going on there .. is that a Micargi Puma ? I'm confused about you saying to use the seat post as the mount for the plates . The plates that accommodate the pillow bearings ? Are those pillow bearings encased with any type of mounting structure ?

I like the photos , but yet still trying to place this concept on my Micargi .... any drilling through the bottom frame tube ? Or as you said I'd it all mounted to the seat post? Now what type of bearings and tpi .. how many teeth per bearing , cause y3s my motorized is built to the hill , I don't need to ride 60mph , just a reliablexpansion set up .. on the left you have a large sprocket , I take it that's the real gearing for your application.. it looks as you have a huge dirt bike engine ? First and foremost I NEED TO GET A PEDAL CRANK SET AS WIDE AS POSSIBLE , my exhaust exhaust expansion chamber is certainly in the way on the right side .. any manufacturer or dealer on ebay that might have a extra wide crank set you could advise me too ?

Anyway thanks for the details . I'm studying your pillow bearing set up , I hope I can design and pull one off .. let me know anyone about the extra wide crank please and thank you all for the support

Try this site: http://custommotoredbicycles.com/wi...r_clearing_4_stroke_motors68mm_bottom_bracket

Having a single 18t rear wheel sprocket makes things a little complicated when choosing sprocket combinations. In an 8-speed rear cassette, things are more forgiving. If you don't have the right pedal ratio in 3rd gear, you can switch gears to 1st and 2nd, or 4th and 5th. With one sprocket, you need to choose the right pedal ratio from the get go.

I'm guessing you have a 36 tooth chainring and a 18 tooth wheel sprocket. In motorizing, that's a negative ratio of .5:1. So, if you want to match your existing motorized gear ratio of 18.26:1, you'll have to create a 36.52:1 sprocket combination. Your engine has a built-in reduced gearing of 4.15:1, I believe. Divide the 44t wheel sprocket and 10t engine sprocket = 44t/10t=4.4:1.

Now multiply both ratios (4.15 x 4.4=18.26:1 effective gear ratio).

Multiply that by your chain ring/wheel gear ratio of .5:1. 18.26. x/.5:1 = 9.23:1.....

Your clutch would burn out, and your bike wouldn't go anywhere with 9.23:1 on your engine.

So, build a jackshaft sprocket combination of 36.52:1.

When it gets to the chainring and wheel sprocket, gearing will decrease to your existing 18.26:1. Serendipity will be that your new pedal ratio will be the same as it was before.

Which gears? Which gears to choose?

You need 36.52:1. The engine provides 4.15:1 gearing.

Divide 36.52:1 by 4.15:1 = 8.8:1.....

Use a 10t engine sprocket and a left-side 30t jackshaft gear.

30:10 = 3:1.....

Divide 8.8:1 by 3:1 = 2.93:1, rounded to 3:1.....

Use a right-side 10t jackshaft gear, and a 30t sprocket on the bottom bracket(You'll have this 30t and your 36t chain ring sprocket there).

30t/10t = 3:1.(again, coincidentally)

So, 4.15:1 x 3:1 x 3:1 = 37.35:1.....

Multiply that 37.35:1 by .5:1 (the chain ring/wheel combo of 16t/36t).

37.35:1 x .5:1 = 18.68:1. This is very close to your existing 18:1 pedal ratio.

GREAT!

HOWEVER, if you want a smaller than 30t buzzing near your left leg, put a smaller gear there. But, your gear ratio decreased, so you'll need a bigger sprocket on the right-side to compensate for the loss.

So, use a 10t engine gear and a 20t left-side jackshaft sprocket.

20t/10t = 2:1.....

4.15:1 x 2 = 8.3:1.....

36:1/8.3:1 = 4.34:1, rounded to 4.4:1.....

Place a right-side 10t jackshaft gear.

Put a 44t sprocket on the bottom bracket(next to your 36t chain ring sprocket).

So, 44t/10t = 4.4:1.....

4.15:1 x 2:1 x 4.4:1 = 36.52:1.....

Run that thru the 36t chain ring/18t(wheel sprocket combination of .5:1).....

4.15 x 2 x 4.4 x .5 = 18.26:1.....

Again, very close to your existing pedal ratio.

So, to summarize which sprockets:

1) 10t engine sprocket;

2) 30t left-side jackshaft sprocket;

3)10t right-side jackshaft sprocket;

4)30t sprocket on the bottom bracket

5)36t chain ring sprocket

6)18t wheel sprocket.....18.68:1 final ratio.

ORRR

1) 10t engine sprocket;

2)20t left-side jackshaft sprocket;

3)10t right-side jackshaft sprocket;

4)44t sprocket on the bottom bracket;

5)36t chain ring sprocket;

18t wheel sprocket.....18.26:1 final ratio.

The big and only difference is if you want a 30t sprocket or a 20t sprocket buzzing by your left leg at the jackshaft.

I hope this helps.

I'm guessing you have a 36 tooth chainring and a 18 tooth wheel sprocket. In motorizing, that's a negative ratio of .5:1. So, if you want to match your existing motorized gear ratio of 18.26:1, you'll have to create a 36.52:1 sprocket combination. Your engine has a built-in reduced gearing of 4.15:1, I believe. Divide the 44t wheel sprocket and 10t engine sprocket = 44t/10t=4.4:1.

Now multiply both ratios (4.15 x 4.4=18.26:1 effective gear ratio).

Multiply that by your chain ring/wheel gear ratio of .5:1. 18.26. x/.5:1 = 9.23:1.....

Your clutch would burn out, and your bike wouldn't go anywhere with 9.23:1 on your engine.

So, build a jackshaft sprocket combination of 36.52:1.

When it gets to the chainring and wheel sprocket, gearing will decrease to your existing 18.26:1. Serendipity will be that your new pedal ratio will be the same as it was before.

Which gears? Which gears to choose?

You need 36.52:1. The engine provides 4.15:1 gearing.

Divide 36.52:1 by 4.15:1 = 8.8:1.....

Use a 10t engine sprocket and a left-side 30t jackshaft gear.

30:10 = 3:1.....

Divide 8.8:1 by 3:1 = 2.93:1, rounded to 3:1.....

Use a right-side 10t jackshaft gear, and a 30t sprocket on the bottom bracket(You'll have this 30t and your 36t chain ring sprocket there).

30t/10t = 3:1.(again, coincidentally)

So, 4.15:1 x 3:1 x 3:1 = 37.35:1.....

Multiply that 37.35:1 by .5:1 (the chain ring/wheel combo of 16t/36t).

37.35:1 x .5:1 = 18.68:1. This is very close to your existing 18:1 pedal ratio.

GREAT!

HOWEVER, if you want a smaller than 30t buzzing near your left leg, put a smaller gear there. But, your gear ratio decreased, so you'll need a bigger sprocket on the right-side to compensate for the loss.

So, use a 10t engine gear and a 20t left-side jackshaft sprocket.

20t/10t = 2:1.....

4.15:1 x 2 = 8.3:1.....

36:1/8.3:1 = 4.34:1, rounded to 4.4:1.....

Place a right-side 10t jackshaft gear.

Put a 44t sprocket on the bottom bracket(next to your 36t chain ring sprocket).

So, 44t/10t = 4.4:1.....

4.15:1 x 2:1 x 4.4:1 = 36.52:1.....

Run that thru the 36t chain ring/18t(wheel sprocket combination of .5:1).....

4.15 x 2 x 4.4 x .5 = 18.26:1.....

Again, very close to your existing pedal ratio.

So, to summarize which sprockets:

1) 10t engine sprocket;

2) 30t left-side jackshaft sprocket;

3)10t right-side jackshaft sprocket;

4)30t sprocket on the bottom bracket

5)36t chain ring sprocket

6)18t wheel sprocket.....18.68:1 final ratio.

ORRR

1) 10t engine sprocket;

2)20t left-side jackshaft sprocket;

3)10t right-side jackshaft sprocket;

4)44t sprocket on the bottom bracket;

5)36t chain ring sprocket;

18t wheel sprocket.....18.26:1 final ratio.

The big and only difference is if you want a 30t sprocket or a 20t sprocket buzzing by your left leg at the jackshaft.

I hope this helps.

Last edited: