Biknut,

Did you weigh the large and small end of the rod, or did you just take half the total rod weight and call it the small end? The actual split might be more like 45/55 for small and large ends respectively, or depending on rod design the differential from small to large might be even bigger.

Your approach sounds fine, but one big issue that could lead you astray is how the bob-weight is attached to the crank assembly. The bob-weight mass needs to be located concentrically or symmetrically about the crank pin. It can not be hanging from the rod which would apply the weight very non-symmetrically about the crankpin.

As you saw in the S&S article on balancing a Hog crank, the crank is disassembled, a pilot installed in the crankpin hole, and the bob-weight in turn attached to the pilot. In the case of the Hog crank the total bob-weight mass is divided by 2 (half the total mass for each flywheel), and 1/2 of the total mass used to balance each flywheel half separately.

I assume your crank is a 3 piece pressed together unit, so it must be pressed apart, the rod removed, and a pilot or the crankpin used to mount the bob-weight symmetrically on the pilot or crankpin. Of course the mass of the crankpin is part of the rotating weight, so must be included in the bob-weight calculation just like the heavy end of the rod must be included as rotating weight in the bob-weight calculation.

If you have a means of fixturing each of your flywheel halves separately, you could also use half the total bob-weight and balance each side of the crank assembly separately just like it was a Hog.

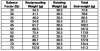

In closing, I'll remind you that the total bob-weight for your system will be the following if you want a 60% balance factor.

0.6 (piston + rings + keepers + pin + small end of rod) + large end of rod + crankpin

If the large and small end of the rod have loose bearings/cages, these are also included in the respective rod end weights.

To achieve static balance may require either weight removal from counterweight, via drilling, or may require addition of weight via heavy metal insertion (drill holes in counterweight and press tungsten alloy into hole to add weight).

Good luck and keep us posted.

Did you weigh the large and small end of the rod, or did you just take half the total rod weight and call it the small end? The actual split might be more like 45/55 for small and large ends respectively, or depending on rod design the differential from small to large might be even bigger.

Your approach sounds fine, but one big issue that could lead you astray is how the bob-weight is attached to the crank assembly. The bob-weight mass needs to be located concentrically or symmetrically about the crank pin. It can not be hanging from the rod which would apply the weight very non-symmetrically about the crankpin.

As you saw in the S&S article on balancing a Hog crank, the crank is disassembled, a pilot installed in the crankpin hole, and the bob-weight in turn attached to the pilot. In the case of the Hog crank the total bob-weight mass is divided by 2 (half the total mass for each flywheel), and 1/2 of the total mass used to balance each flywheel half separately.

I assume your crank is a 3 piece pressed together unit, so it must be pressed apart, the rod removed, and a pilot or the crankpin used to mount the bob-weight symmetrically on the pilot or crankpin. Of course the mass of the crankpin is part of the rotating weight, so must be included in the bob-weight calculation just like the heavy end of the rod must be included as rotating weight in the bob-weight calculation.

If you have a means of fixturing each of your flywheel halves separately, you could also use half the total bob-weight and balance each side of the crank assembly separately just like it was a Hog.

In closing, I'll remind you that the total bob-weight for your system will be the following if you want a 60% balance factor.

0.6 (piston + rings + keepers + pin + small end of rod) + large end of rod + crankpin

If the large and small end of the rod have loose bearings/cages, these are also included in the respective rod end weights.

To achieve static balance may require either weight removal from counterweight, via drilling, or may require addition of weight via heavy metal insertion (drill holes in counterweight and press tungsten alloy into hole to add weight).

Good luck and keep us posted.

Last edited: