Outrunner

New Member

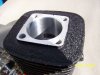

I removed the cylinder from my engine and used a brake cylinder hone

to "scuff" the cylinder to help brake in the piston rings. I've done

this on two of the Chinese chrome cylinders, and it has greatly improved the

break in period of the rings. The key factor to doing this properly is to liberally

use mineral spirits and only briefly stroke the bore with a variable speed

drill at a slow speed, just enough to de-glaze the cylinder. The stock chrome cylinder liner is too smooth and causes excessive uneven and extended brake

in time. I have over 400 miles on both engines and the cylinders have a much

better ring pattern after inspection.I've used only Amsoil Sabre full synthetic

oil from day one, at a 40:1 ratio and after about 100-150 miles I switch to a

50:1 ratio. I know that someone will start scolding me for honing a chromed

cylinder liner, but they're cheap to buy and as it turned out, it works great!

The key point is to briefly stroke the cylinder using lots of mineral spirits,

just enough to scuff it in a cross hatch pattern. That will help the piston and rings to seat in much more evenly and faster, plus it adds additional lubrication too. An easy way to slide the cylinder back onto the piston, is to use a piece of plywood under the piston to hold it level, and a hose clamp to compress the rings, and simply slide the

cylinder back on. A flat sanding tool that can be bought at a hobby store is

excellent for leveling the cylinder and cylinder head mating surfaces for a

nice fit too.

to "scuff" the cylinder to help brake in the piston rings. I've done

this on two of the Chinese chrome cylinders, and it has greatly improved the

break in period of the rings. The key factor to doing this properly is to liberally

use mineral spirits and only briefly stroke the bore with a variable speed

drill at a slow speed, just enough to de-glaze the cylinder. The stock chrome cylinder liner is too smooth and causes excessive uneven and extended brake

in time. I have over 400 miles on both engines and the cylinders have a much

better ring pattern after inspection.I've used only Amsoil Sabre full synthetic

oil from day one, at a 40:1 ratio and after about 100-150 miles I switch to a

50:1 ratio. I know that someone will start scolding me for honing a chromed

cylinder liner, but they're cheap to buy and as it turned out, it works great!

The key point is to briefly stroke the cylinder using lots of mineral spirits,

just enough to scuff it in a cross hatch pattern. That will help the piston and rings to seat in much more evenly and faster, plus it adds additional lubrication too. An easy way to slide the cylinder back onto the piston, is to use a piece of plywood under the piston to hold it level, and a hose clamp to compress the rings, and simply slide the

cylinder back on. A flat sanding tool that can be bought at a hobby store is

excellent for leveling the cylinder and cylinder head mating surfaces for a

nice fit too.

Attachments

Last edited: