el Diablo Guapo

Member

Got my clutch shaft friday, put it in on saturday, and took it for about 1 mile or so test ride. It seems solid so i will be riding to work once again!

It was the first time i had installed a clutch shaft so i was a little slow as i thought through what i needed to do. I am outlining the details here, mostly as a reminder to myself for next time. I feel confident there will be a next time because i have (now) seen so many pictures of shafts with similar issues. (see how i removed the old, destroyed one here: https://motorbicycling.com/threads/my-clutch-shaft-the-definition-of-fubar.63469/ )

I was able to perform this operation without removing the engine from the bike.

Having the gearpuller from the kit was important, I used it to take the gear off and to get the chain sprocket seated completely. (more later)

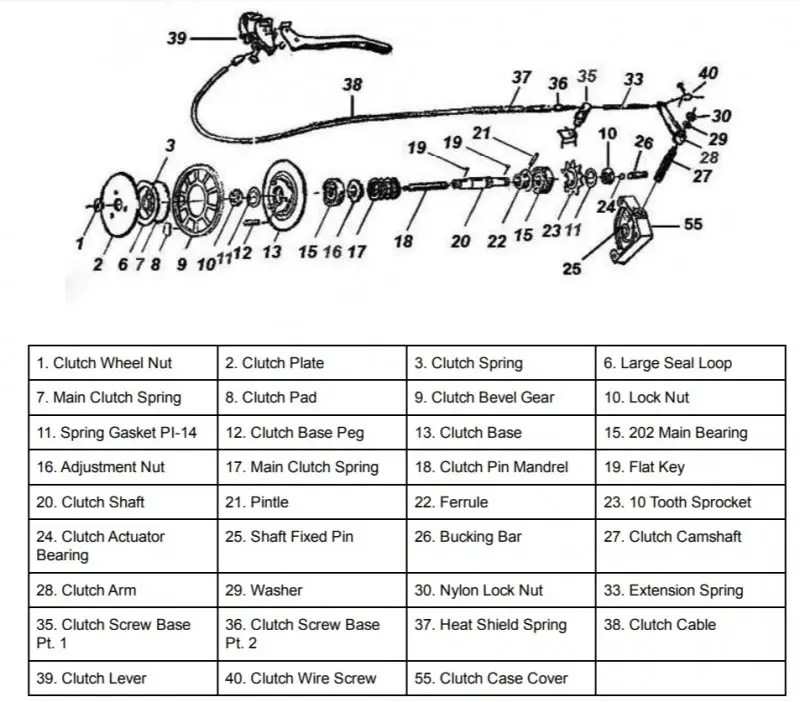

i ordered a clutch shaft with the spring(#17) and clutch pin mandrel(#18) pre assembled

I was concerned because the new shaft was a little larger diameter than the old one, making for what would have been a (very) tight interference fit. I ultimately used my drill as a lathe to file off a little more of the shaft and get an interference/press fit i was happier with. (pictures to follow)

I installed the woodruff key on the gear (clutch base) end with pliers, and then seated it by tapping a few times with a small hammer.

Mounting the clutch base (#13) was a slight challenge. I used my 3 pound hammer as a crude press, and slipped a 15mm socket over the shaft to direct the force where i wanted it. Initial pressing was done on a wood block, to minimize deforming the shaft and threads. On the wood block however, i could not get the clutch base to completely seat, it absorbed too much force, leaving a small gap between the clutch base and the bearing. i ultimately laid a piece of smooth steel on the concrete floor and two taps later the gap was closed.

The clutch base is made two pieces that turn independantly until joined by the action of the clutch. There appears to be ball bearings in this assembly and i wish now that i had put a little grease in there while i had it apart. A few posts have mentioned a rattling sound coming from the engine case even though everything is tight. I think this may be the source of that sound. Any thoughts? Can this be greased while installed?

I put the toothed lock washer (#11) and nut (#10) on and cranked it down. Is there a torque recommendation for these? I am nervous about the small threads, and the nut came off easily at disassembly. BTW i needed a new toothed washer for one side and the remaining old one looked squished and less than effective. I could not find new metric ones (14mm) but got 2 new 1/2" ones for $1.28 at Lowes. They were slighty too small so i held them with pliers and touched them up with the dremel grinder. I found new ones on mcmaster carr, but did not want to wait - https://www.mcmaster.com/#91106a137/=19q3yro Original equipment: http://www.bikeberry.com/spring-gasket-pi-14.html Even the clutch rebuild kits do not seem to contain the nuts and locking washers !?! Though I would not reccomend re-using these tooth lock washers, since they seem to be squished and so, less effective. You may have no choice. I am going to order a box from Mcmaster.com for the future.

Anyway i used my hammer to gently tap the clutch assembly back into position, the chain sprocket side bearing was already in place, and again i used a 15mm socket as my impact surface to prevent damage from the hammer.

On the chain sprocket side i installed the woodruff (shear) key in its slot and seated it by tapping it. I had to use a long screwdriver to reach it, but it went down into the keyway nicely. This may have been part of why my old one failed, not enough key in the slot...

Then i mounted the chain sprocket(#23). It slipped on a ways, but then i put on the gear puller, removed the center screw and tapped the sprocket all the way to the bearing. Again, this may have contributed to the failure of the old shaft, it may have never been completely tightened up against the bearing. I do not trust the tiny threads on this nut and shaft to do the entire job of seating these parts - in fact my old shaft was stripped so i am even more suspicious. Added the other new tooth washer (#11) and the old nut (#10) held the other side of the assembly with a bar across the clutch plate pegs and cranked down the nut (again torque?). The inner portion of the clutch spun smoothly, while the gears were meshed together.

I have a feeling that "slop" or space between any of the assembled pieces, bearings, housing, etc. contribute to the failures of these assemblies. They installation could look and feel tight, then shift and let something move (apparently often the chain sprocket).

Reinstalled the clutch plate(#2) and spring(#3) and flower nut (#1) and retaining screw (not pictured) - adjusted the clutch before adding the retaining screw.

Went for a ride about a mile or two and everything seems to be working well.

I did not take any pictures, but i took one with the old parts of using my drill as a lathe. i could not just chuck up shaft, it was too big. I chcked up a deep socket (19mm =~3/4"), put a nut on the shaft, put the shaft in the socket, used a zip tie (or a friend) to pull the trigger, and held a file flat/parallel against the far end of the shaft. Check with digital calipers and with bearing for fit. But if it fits, it (might be) too much. I wanted some interference, but not as much s it came with...

It was the first time i had installed a clutch shaft so i was a little slow as i thought through what i needed to do. I am outlining the details here, mostly as a reminder to myself for next time. I feel confident there will be a next time because i have (now) seen so many pictures of shafts with similar issues. (see how i removed the old, destroyed one here: https://motorbicycling.com/threads/my-clutch-shaft-the-definition-of-fubar.63469/ )

I was able to perform this operation without removing the engine from the bike.

Having the gearpuller from the kit was important, I used it to take the gear off and to get the chain sprocket seated completely. (more later)

i ordered a clutch shaft with the spring(#17) and clutch pin mandrel(#18) pre assembled

I was concerned because the new shaft was a little larger diameter than the old one, making for what would have been a (very) tight interference fit. I ultimately used my drill as a lathe to file off a little more of the shaft and get an interference/press fit i was happier with. (pictures to follow)

I installed the woodruff key on the gear (clutch base) end with pliers, and then seated it by tapping a few times with a small hammer.

Mounting the clutch base (#13) was a slight challenge. I used my 3 pound hammer as a crude press, and slipped a 15mm socket over the shaft to direct the force where i wanted it. Initial pressing was done on a wood block, to minimize deforming the shaft and threads. On the wood block however, i could not get the clutch base to completely seat, it absorbed too much force, leaving a small gap between the clutch base and the bearing. i ultimately laid a piece of smooth steel on the concrete floor and two taps later the gap was closed.

The clutch base is made two pieces that turn independantly until joined by the action of the clutch. There appears to be ball bearings in this assembly and i wish now that i had put a little grease in there while i had it apart. A few posts have mentioned a rattling sound coming from the engine case even though everything is tight. I think this may be the source of that sound. Any thoughts? Can this be greased while installed?

I put the toothed lock washer (#11) and nut (#10) on and cranked it down. Is there a torque recommendation for these? I am nervous about the small threads, and the nut came off easily at disassembly. BTW i needed a new toothed washer for one side and the remaining old one looked squished and less than effective. I could not find new metric ones (14mm) but got 2 new 1/2" ones for $1.28 at Lowes. They were slighty too small so i held them with pliers and touched them up with the dremel grinder. I found new ones on mcmaster carr, but did not want to wait - https://www.mcmaster.com/#91106a137/=19q3yro Original equipment: http://www.bikeberry.com/spring-gasket-pi-14.html Even the clutch rebuild kits do not seem to contain the nuts and locking washers !?! Though I would not reccomend re-using these tooth lock washers, since they seem to be squished and so, less effective. You may have no choice. I am going to order a box from Mcmaster.com for the future.

Anyway i used my hammer to gently tap the clutch assembly back into position, the chain sprocket side bearing was already in place, and again i used a 15mm socket as my impact surface to prevent damage from the hammer.

On the chain sprocket side i installed the woodruff (shear) key in its slot and seated it by tapping it. I had to use a long screwdriver to reach it, but it went down into the keyway nicely. This may have been part of why my old one failed, not enough key in the slot...

Then i mounted the chain sprocket(#23). It slipped on a ways, but then i put on the gear puller, removed the center screw and tapped the sprocket all the way to the bearing. Again, this may have contributed to the failure of the old shaft, it may have never been completely tightened up against the bearing. I do not trust the tiny threads on this nut and shaft to do the entire job of seating these parts - in fact my old shaft was stripped so i am even more suspicious. Added the other new tooth washer (#11) and the old nut (#10) held the other side of the assembly with a bar across the clutch plate pegs and cranked down the nut (again torque?). The inner portion of the clutch spun smoothly, while the gears were meshed together.

I have a feeling that "slop" or space between any of the assembled pieces, bearings, housing, etc. contribute to the failures of these assemblies. They installation could look and feel tight, then shift and let something move (apparently often the chain sprocket).

Reinstalled the clutch plate(#2) and spring(#3) and flower nut (#1) and retaining screw (not pictured) - adjusted the clutch before adding the retaining screw.

Went for a ride about a mile or two and everything seems to be working well.

I did not take any pictures, but i took one with the old parts of using my drill as a lathe. i could not just chuck up shaft, it was too big. I chcked up a deep socket (19mm =~3/4"), put a nut on the shaft, put the shaft in the socket, used a zip tie (or a friend) to pull the trigger, and held a file flat/parallel against the far end of the shaft. Check with digital calipers and with bearing for fit. But if it fits, it (might be) too much. I wanted some interference, but not as much s it came with...

Last edited: