TheSignGuy

Member

Hello so I have found a solution to make my 3HP go 30 mph,

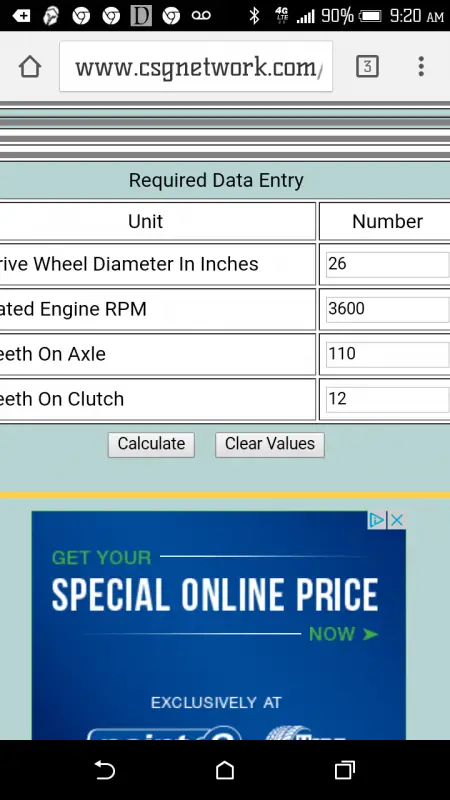

Instead of then shaft idea provided by Dave which involved:

Using several Jack shafts "A 12t clutch sprocket to a 24t Jack shaft to 10 Jack shaft over to a 47 rear sprocket."

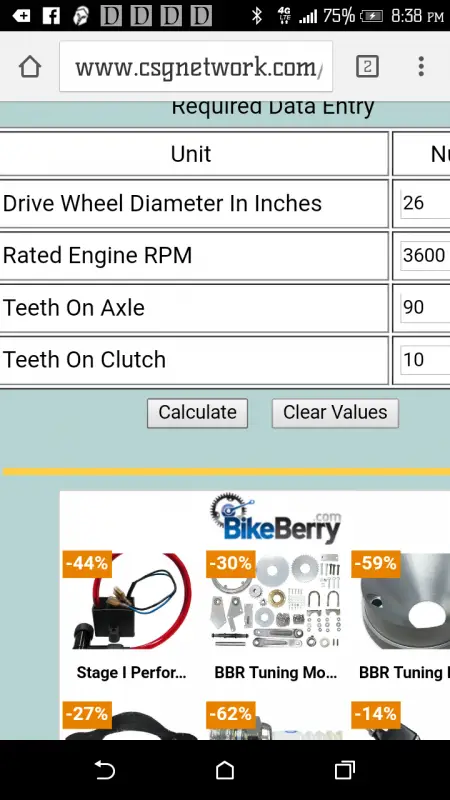

I have found a cheaper format option which involves a 10t centrifugal clutch (instead of keeping my 12t)

Installing a 80t rear motorcycle sprocket which will give me accurate specs as listed:

note here is a before and after problem pre calculated due to there are no 110t sprockets.

This is before considering Jack shaft considering....

There is no such thing as a 110t rear sprocket which cannot be valid without Jack shafting.

Here is after playing/lowering clutch tooth range....

This is the correct and slightly available option as listed that will work for my bike without destroying the bike paint with a bunch of sloppy WA STATE CHEAP WELDS

My main concern at the time is the rack has a bit of play in it would it be wise to get a light steel sheet plate welded over the sites of the rack to the frame to take out the play access?

It already needs a paint job so before welding I will have it grinded down in that area and have a paint shop fix the raw weld color area.

In addition, HOW do I true a wheel I heard if it wobbles left you adjust the right side by tightening 1/4 at a time and loosen the opposing side.

Wobbly rack front ant side view.

Also take note where the "triangle like sides of the rack are that's where I feel a half sheet of steel would work best.

Instead of then shaft idea provided by Dave which involved:

Using several Jack shafts "A 12t clutch sprocket to a 24t Jack shaft to 10 Jack shaft over to a 47 rear sprocket."

I have found a cheaper format option which involves a 10t centrifugal clutch (instead of keeping my 12t)

Installing a 80t rear motorcycle sprocket which will give me accurate specs as listed:

note here is a before and after problem pre calculated due to there are no 110t sprockets.

This is before considering Jack shaft considering....

There is no such thing as a 110t rear sprocket which cannot be valid without Jack shafting.

Here is after playing/lowering clutch tooth range....

This is the correct and slightly available option as listed that will work for my bike without destroying the bike paint with a bunch of sloppy WA STATE CHEAP WELDS

My main concern at the time is the rack has a bit of play in it would it be wise to get a light steel sheet plate welded over the sites of the rack to the frame to take out the play access?

It already needs a paint job so before welding I will have it grinded down in that area and have a paint shop fix the raw weld color area.

In addition, HOW do I true a wheel I heard if it wobbles left you adjust the right side by tightening 1/4 at a time and loosen the opposing side.

Wobbly rack front ant side view.

Also take note where the "triangle like sides of the rack are that's where I feel a half sheet of steel would work best.