I wasn't happy with any mounts I could find, so I made my own. The exhaust clamps were crushing the tubing and still weren't tight enough.

I drilled the two bolt holes, countersunk the bolts with a drill bit, then used an end mill to get a flat countersink for the bolts to sit on. After that, I cut the mount to length in the dry cut saw, then split them with my jigsaw. After that, I bolted the two halves back together, drilled a 1/4" pilot hole, drilled a 7/8" hole, ran a .99" reamer (all I had) through to straighten the hole up, then finished it with a 1" bit. Since it had little to cut, and the reamer had made it round, the 1" bit still made a perfect hole.

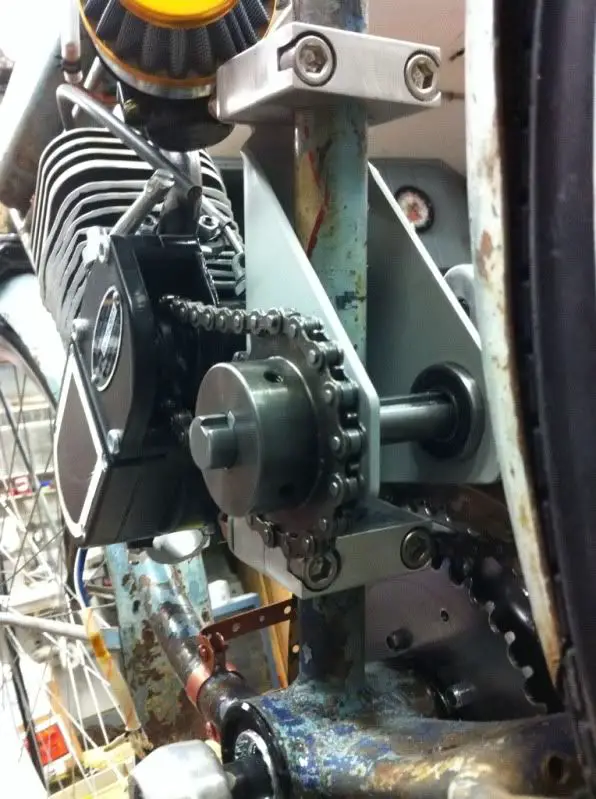

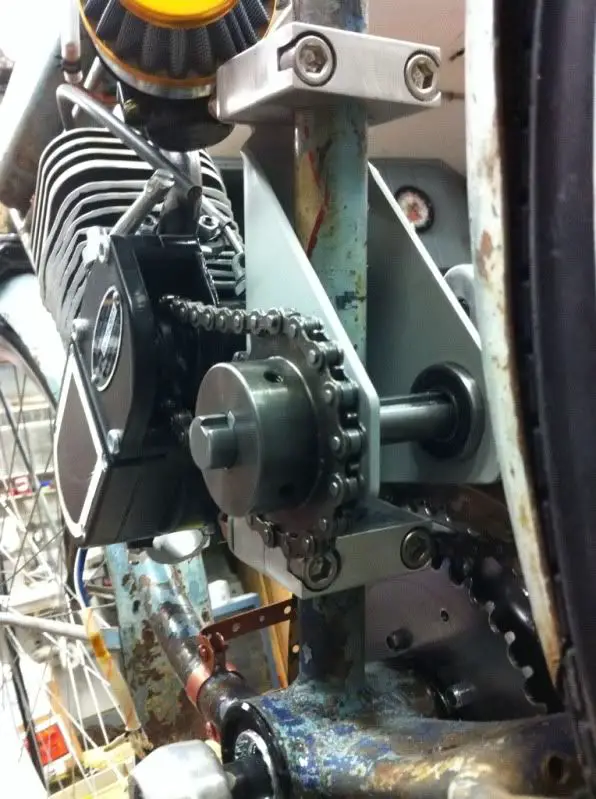

It took a few versions, but I got the front mount done finally. It's adjustable, so the engine can be moved up and down to set chain tension.

I drilled the two bolt holes, countersunk the bolts with a drill bit, then used an end mill to get a flat countersink for the bolts to sit on. After that, I cut the mount to length in the dry cut saw, then split them with my jigsaw. After that, I bolted the two halves back together, drilled a 1/4" pilot hole, drilled a 7/8" hole, ran a .99" reamer (all I had) through to straighten the hole up, then finished it with a 1" bit. Since it had little to cut, and the reamer had made it round, the 1" bit still made a perfect hole.

It took a few versions, but I got the front mount done finally. It's adjustable, so the engine can be moved up and down to set chain tension.