I have been meaning to put together a quick tutorial on how to flat lap a cylinder head since the question does get asked on occasion. Tonight I finally did just that. Some may remember the 3hp Briggs I found a while back. It's been sitting on the work bench partially disassembled, so I figured what better candidate. This procedure is general in that it applies to OHV heads as well. Without further ado...

Materials:

- Wet/dry sandpaper sheets, at least 400 grit.

- Masking tape.

- Layout fluid like Dykem if you have it or a permanent marker if you don't.

- Soapy water. Light oil can be used too, but it's much messier, so I don't recommend it.

- Gloves. Okay, and safety goggles.

1.) You'll need a clean flat surface, the more precise the better. I have a real granite surface plate at my disposal that is flat to ±0.00006". For the purposes of this tutorial, a piece of decent window glass will suffice. I have even resorted to a polished concrete floor for quick 'n' dirty work. Tape the corners of your sandpaper down like this

2.) Put a little soapy water on the sandpaper. This keeps the paper from loading up and makes it last a bit longer:

3.)Make sure the head is completely clean with no gasket residue. You can put layout fluid/marker on the gasket surface now or wait until the next step. Put the head on the wet sandpaper and make a few swipes in a figure-8 motion, NOT a circle. Keep the pressure as even across the part as you can:

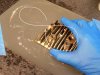

4.) Have a quick look for high and low spots. Here you can see the high spots are mostly around the head bolt holes ut the layout fluid/marker on there if you haven't yet:

ut the layout fluid/marker on there if you haven't yet:

5.) Use some more elbow grease. Rotate the part occasionally as you lap it. Check progress as you go. Low spots will still have color like this:

Keep lapping until you are comfortable that they are gone.

6.) Finish up with a relatively fine paper. Like I said before, 400 is probably a good minimum grit. I started with 400 and went directly to 1000. This is why I recommend using gloves:

7.) This is what I ended up with. Almost all of the hills and valleys are gone and the gasket has an RA more than fit for even a copper gasket:

see next post for step by step pics

Materials:

- Wet/dry sandpaper sheets, at least 400 grit.

- Masking tape.

- Layout fluid like Dykem if you have it or a permanent marker if you don't.

- Soapy water. Light oil can be used too, but it's much messier, so I don't recommend it.

- Gloves. Okay, and safety goggles.

1.) You'll need a clean flat surface, the more precise the better. I have a real granite surface plate at my disposal that is flat to ±0.00006". For the purposes of this tutorial, a piece of decent window glass will suffice. I have even resorted to a polished concrete floor for quick 'n' dirty work. Tape the corners of your sandpaper down like this

2.) Put a little soapy water on the sandpaper. This keeps the paper from loading up and makes it last a bit longer:

3.)Make sure the head is completely clean with no gasket residue. You can put layout fluid/marker on the gasket surface now or wait until the next step. Put the head on the wet sandpaper and make a few swipes in a figure-8 motion, NOT a circle. Keep the pressure as even across the part as you can:

4.) Have a quick look for high and low spots. Here you can see the high spots are mostly around the head bolt holes

5.) Use some more elbow grease. Rotate the part occasionally as you lap it. Check progress as you go. Low spots will still have color like this:

Keep lapping until you are comfortable that they are gone.

6.) Finish up with a relatively fine paper. Like I said before, 400 is probably a good minimum grit. I started with 400 and went directly to 1000. This is why I recommend using gloves:

7.) This is what I ended up with. Almost all of the hills and valleys are gone and the gasket has an RA more than fit for even a copper gasket:

see next post for step by step pics

Last edited:

at that I know a guy who f***ed his wife's counter and had to sell his toys to buy a new one because he for got sandpaper

at that I know a guy who f***ed his wife's counter and had to sell his toys to buy a new one because he for got sandpaper