Say, the CEOs of Affordable Go Karts, Sportsman Flyer and Venice Motor Bikes have serious skills. I want to mention the Giant Stiletto bicycle for which Staton-Inc engineered a shift kit that enabled the Stiletto to be motorized. Giant discontinued building the Stiletto decades ago. It was a much better bicycle than the Sting Ray. It's the best motorized bicycle with shift kit. I fit mine with the Honda GXH50 in-frame. This bike with 20 inch front tire turns and handles very well, with the quality frame and 3 inch wide tires it is very stable, with shift kit I'm sure I was going at least 40mph, the Shimano rear freewheel held up even after speed shifting and my friend was even doing wheelies on it and It is a good looking motorized bicycle.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If Someone Could Kindly Post Pictures of The Best Motorized Bicycle in the World.

- Thread starter zean

- Start date

Sidewinder Jerry

Well-Known Member

My little 4 stroke RS 35 has held up for 12 years well worth what I paid for it.Thank you Sidewinder Jerry. Yes, the properly built high quality motorized bicycle is a bargain because the parts accomplish their intended purpose, have a foundation of a lot of R and D from the manufacturer and they don't break. The high quality motorized bicycle may cost three times more, It is literally ten times better.

Sidewinder Jerry

Well-Known Member

What kind of shift kit are you using? I use an SI Triple chainring shift kit.Say, the CEOs of Affordable Go Karts, Sportsman Flyer and Venice Motor Bikes have serious skills. I want to mention the Giant Stiletto bicycle for which Staton-Inc engineered a shift kit that enabled the Stiletto to be motorized. Giant discontinued building the Stiletto decades ago. It was a much better bicycle than the Sting Ray. It's the best motorized bicycle with shift kit. I fit mine with the Honda GXH50 in-frame. This bike with 20 inch front tire turns and handles very well, with the quality frame and 3 inch wide tires it is very stable, with shift kit I'm sure I was going at least 40mph, the Shimano rear freewheel held up even after speed shifting and my friend was even doing wheelies on it and It is a good looking motorized bicycle.

The shift kit parts are on page 9 and 10 under the category of Staton-Inc CNC machined parts except for the engine mounts. I'm sure he could make those or he has them in stock. If a person wanted to build a very good motorized bicycle and finds a Giant Stiletto on Craig's List, then he could buy the jackshaft kit. The parts bolt right on and the drive train alignment is built into the parts.

Last edited:

Sidewinder Jerry

Well-Known Member

The shift kit parts are on page 9 and 10 under the category of Staton-Inc CNC machined parts except for the engine mounts. I'm sure he could make those or he has them in stock. If a person wanted to build a very good motorized bicycle and finds a Giant Stiletto on Craig's List, then he could buy the jackshaft kit. The parts bolt right on and the drive train alignment is built into the parts.

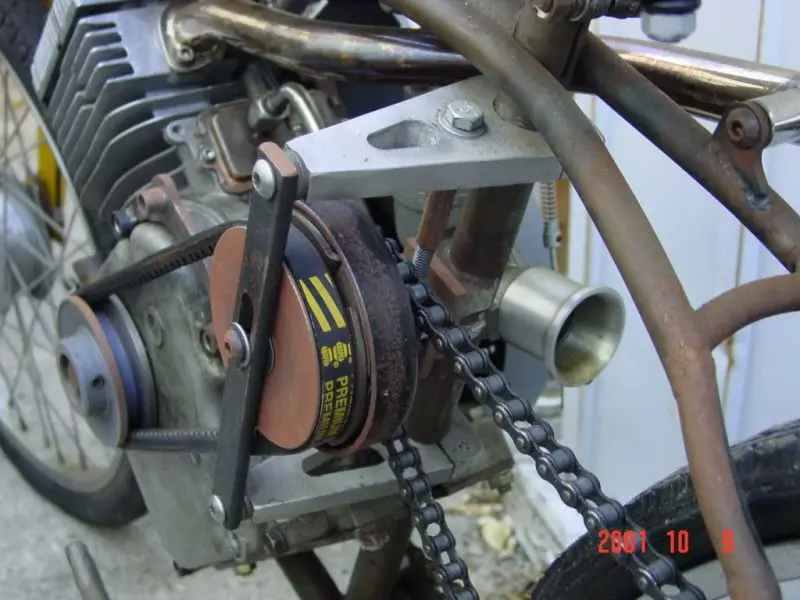

Though it's a discontinued item here's what my Staton Inc shift kit looks like:

Staton Inc Shift Kit

Well after 11 years of service I've decided to retire the auto shift LandRider. I did mods to the derailleur and it was working really good. However the hanger broke on the frame. It's a steel frame so I could repair it with a little welding. Still LandRider went out of business 5 years ago. So...

All shifting is done with the left hand and a color coding system is used on the 3x7 the only time a front chainring is shifted is when in rear sprockets (3) or (5). For a total of 9 sequential non-redundant ratios. I used a custom built 7 speed 34-13 freewheel. The reduction range is 66.79:1 to 16.25:1. Take off gears are 1(1) for starts up steep hills and 2(3) for all other starts. This system allows me to maintain an rpm on the tech between 6000-7000.

Red

1(1-3)

Heavy load pulling/steep hill climbing.

Yellow

2(3-5)

Around town general use.

Green

3(5-7)

Open road use.

Last edited:

Say, Venice Motor Bikes is such a prolific designer of motorized bicycles that I would like to see him write a book that shows a history of his builds from when he was starting out and experimenting up until now. I realize this would take a lot of time, maybe more than five years. The book could have one picture of each of a hundred completed builds with a written explanation under each picture describing for example: the gas tank, hubs, engine, frame, handle bars, exhaust forks or whatever he feels like describing to capture the feeling of the build to the reader. This would take a team effort. In this business one person would have to do it all like a throw back to simpler times. I don’t know if a book like this is possible because of all the work involved.

Venice Motor Bikes

Custom Builder / Dealer/Los Angeles

I would love to write a book... but I can't read or write.

Tom from Rubicon

Well-Known Member

79cc and bicycle tires

Tom from Rubicon your motorized bicycle is a work of art. They say that people can tell a lot about a person by the bike they ride. All the parts of your bike were already designed. You put it together by hand. When you were almost finished I believe you said that if you had known how difficult the build was going to be that you would have had the designer build it for you. Now the bike is strongly connected to you.

Lasted 1300 miles... I was banned from this forum for arguing with Damien about the quality of the bicycle engines .com Zeda triple 40 and phantom 85 and since my ban it seems my point has been made... By another member and now Damien himself...

Attachments

Last edited:

Tony01

Well-Known Member

When you say “best” it really depends on your definition. For me it means, “best for putting the highest miles in”.

Just from my own experiences, ebikes are the best. It shows in the community. I have met a few other gas bikers on the streets, only one of them was a real rider. His bike was way too slow however, his top speed of 28mph was lower than the speed my clutch locked on the 212. He eventually went to electric (his slow bike was a 4-stroke huasheng 50cc that he put over 10000 miles on). Two others, despite having 4-strokes built for reliability, would whine about riding 15 miles one way to my house even when I would do a trip like that twice daily for years on my 212. My whizzer friend only made it out to my house ONE time. It’s kinda pathetic. I would ride out to him a dozen miles and then we would “talk shop” as he got ready for 30 minutes, then we’d do a so called ride 3-6 miles round trip to eat, talk more shop. Been like that with every gas biker I’ve met.

The EV community is different. Dozens of real riders. Have no problem doing 30, 50, 100 mile trips weekly or daily. The conversations are a lot simpler... “hey man you wanna ride?” “Yea I’ll meet you at that Chargepoint in 30 minutes...” No whining. Just putting the miles in. We talk shop too... when charging away from home, sharing a meal, taking a break, in the open air sometimes with nice eye candy walking by... not in the garage drinking beer, whining about the junk parts of an engine kit.

“Best”... for talking shop with random dudes everywhere you stop more than actually riding... gas bikes for sure.

“Best”.. for moving your soul, not being bothered, not wrenching on the bike weekly or daily... ebikes hands down.

You guys can talk about the best designs all you want, that’s not what I see- I see Wrench with his 40k mile Whizzer.

Just from my own experiences, ebikes are the best. It shows in the community. I have met a few other gas bikers on the streets, only one of them was a real rider. His bike was way too slow however, his top speed of 28mph was lower than the speed my clutch locked on the 212. He eventually went to electric (his slow bike was a 4-stroke huasheng 50cc that he put over 10000 miles on). Two others, despite having 4-strokes built for reliability, would whine about riding 15 miles one way to my house even when I would do a trip like that twice daily for years on my 212. My whizzer friend only made it out to my house ONE time. It’s kinda pathetic. I would ride out to him a dozen miles and then we would “talk shop” as he got ready for 30 minutes, then we’d do a so called ride 3-6 miles round trip to eat, talk more shop. Been like that with every gas biker I’ve met.

The EV community is different. Dozens of real riders. Have no problem doing 30, 50, 100 mile trips weekly or daily. The conversations are a lot simpler... “hey man you wanna ride?” “Yea I’ll meet you at that Chargepoint in 30 minutes...” No whining. Just putting the miles in. We talk shop too... when charging away from home, sharing a meal, taking a break, in the open air sometimes with nice eye candy walking by... not in the garage drinking beer, whining about the junk parts of an engine kit.

“Best”... for talking shop with random dudes everywhere you stop more than actually riding... gas bikes for sure.

“Best”.. for moving your soul, not being bothered, not wrenching on the bike weekly or daily... ebikes hands down.

1300 miles is nothing.Lasted 1300 miles... I was banned from this forum for arguing with Damien about the quality of the bicycle engines .com Zeda triple 40 and phantom 85 and since my ban it seems my point has been made... By another member and now Damien himself...

You guys can talk about the best designs all you want, that’s not what I see- I see Wrench with his 40k mile Whizzer.

Tom from Rubicon

Well-Known Member

Truth be told, I have had a crush on Whizzers. It was love at first sight. It was 1988.

Standing road side in a rural Northeastern Illinois hamlet when what to my wondering eyes come putting by were seven Whizzers. Ridden by guys in their fifties and sixties. I haled them, and they stopped.

We chatted for a quarter hour while I gave the bikes a serious walk around. The bikes were all Schwinn's.

of the era. I never got over it. 1948 - 1952 Whizzer Pacemaker (topspeed.com)

Tom

Standing road side in a rural Northeastern Illinois hamlet when what to my wondering eyes come putting by were seven Whizzers. Ridden by guys in their fifties and sixties. I haled them, and they stopped.

We chatted for a quarter hour while I gave the bikes a serious walk around. The bikes were all Schwinn's.

of the era. I never got over it. 1948 - 1952 Whizzer Pacemaker (topspeed.com)

Tom

Sidewinder Jerry

Well-Known Member

I got 4452 hours on my RS 35. If you figure a 15 mph average speed that comes to 66,780 miles. Some of us enjoy going under 30 mph.When you say “best” it really depends on your definition. For me it means, “best for putting the highest miles in”.

Just from my own experiences, ebikes are the best. It shows in the community. I have met a few other gas bikers on the streets, only one of them was a real rider. His bike was way too slow however, his top speed of 28mph was lower than the speed my clutch locked on the 212. He eventually went to electric (his slow bike was a 4-stroke huasheng 50cc that he put over 10000 miles on). Two others, despite having 4-strokes built for reliability, would whine about riding 15 miles one way to my house even when I would do a trip like that twice daily for years on my 212. My whizzer friend only made it out to my house ONE time. It’s kinda pathetic. I would ride out to him a dozen miles and then we would “talk shop” as he got ready for 30 minutes, then we’d do a so called ride 3-6 miles round trip to eat, talk more shop. Been like that with every gas biker I’ve met.

The EV community is different. Dozens of real riders. Have no problem doing 30, 50, 100 mile trips weekly or daily. The conversations are a lot simpler... “hey man you wanna ride?” “Yea I’ll meet you at that Chargepoint in 30 minutes...” No whining. Just putting the miles in. We talk shop too... when charging away from home, sharing a meal, taking a break, in the open air sometimes with nice eye candy walking by... not in the garage drinking beer, whining about the junk parts of an engine kit.

“Best”... for talking shop with random dudes everywhere you stop more than actually riding... gas bikes for sure.

“Best”.. for moving your soul, not being bothered, not wrenching on the bike weekly or daily... ebikes hands down.

1300 miles is nothing.

You guys can talk about the best designs all you want, that’s not what I see- I see Wrench with his 40k mile Whizzer.

Tony01

Well-Known Member

I got 4452 hours on my RS 35. If you figure a 15 mph average speed that comes to 66,780 miles. Some of us enjoy going under 30 mph.

I can understand that, but most of us here are trying to go 40-50mph at least. And it’s REALLY difficult to build something for that speed range that’s reliable enough to get you to work 5 days a week. It’s that grey area between mopeds and motorcycles. I’ve gone slow too when I had a proper road bicycle. It’s fun but it’s not safe at all when cars are flying by you going 20-30mph more. I like to be riding the same speed as the cars. I have friends that have hit or been hit by cars whilst going 20mph in the bike lane. No thanks...

Hi Tony01. How many tens of thousands of miles did you ride on your 212 build? If I remember correctly was it a motorcycle frame that you expertly converted to a motorized bicycle and did a lot of work on the fork? That was a very nice bike. I almost bought it from you except at that time something diverted my attention.

Tom from Rubicon

Well-Known Member

Gratuitous left side photo of the drive train, also illustrating the Indian tool box by Taylor.

Tom

Tom

Tony01

Well-Known Member

Hey Zean yeah that was my 2nd 212 build that I put 7000 miles on.Hi Tony01. How many tens of thousands of miles did you ride on your 212 build? If I remember correctly was it a motorcycle frame that you expertly converted to a motorized bicycle and did a lot of work on the fork? That was a very nice bike. I almost bought it from you except at that time something diverted my attention.

My first one was a cruiser, put over 18k. Rode rain or shine.

Both builds required insane amounts of maintenance. Did the front pads and rear tire at the same time every 1200 miles. Used to buy clutches in 3 packs. All the regular stuff. Oiling the clutch after every ride. Putting new chains and sprockets sometimes. The constant cleaning.

My ebike has 8k. Still on its 2nd front set of brake shoes and rear tire. Rarely use the mechanical brake thanks to the variable regen. Has a car charger port with automatic signaling hardwired to an onboard 110/220v charger, with extra plug to share a 220v car charge handle with a friend. Store it at around 50% and top it off before you ride. You can build a complete one with similar specs, using a $450 Chinese ebike frame, easily for under $4k. Nothing to maintain really...

Great engineering. Engine cradle design is great. Loving the heat sink on the exhaust pipe. Mine used to glow in the dark.Gratuitous left side photo of the drive train, also illustrating the Indian tool box by Taylor.

View attachment 110527

Tom

Attachments

Last edited:

Sidewinder Jerry

Well-Known Member

I personally won't use bike lanes or shoulders if I don't feel they're safe to use. Some bike lanes are poorly designed.I can understand that, but most of us here are trying to go 40-50mph at least. And it’s REALLY difficult to build something for that speed range that’s reliable enough to get you to work 5 days a week. It’s that grey area between mopeds and motorcycles. I’ve gone slow too when I had a proper road bicycle. It’s fun but it’s not safe at all when cars are flying by you going 20-30mph more. I like to be riding the same speed as the cars. I have friends that have hit or been hit by cars whilst going 20mph in the bike lane. No thanks...

Unfortunately many don't understand good cycling techniques and that's what causes them to be in an accident. What I see that gets many cyclist hit is not knowing what the Far Right law means.

What the Far Right law means is if the lane is wide enough for Lane Sharing then the Cyclist is to ride as far to the right as safely possible. If a lane isn't wide enough for a vehicle to pass a cyclist riding to the Far Right by 3 feet without having to change lanes; then the cyclist has the right to use the entire lane.

Therefore in narrow lanes the safest place for a cyclist is in the center of the lane. This is known as Lane Control. When a cyclist rides to the Far Right in narrow lanes it encourages passing vehicles to do squeeze bys on the cyclist; and possibly being side swiped by the vehicle. With Lane Control it causes passing vehicles to have to change lanes to pass; just like they'd have to do with any other slow moving vehicle.

Many will say it'll make motorist angry. My feeling is better them Mad than me Dead. If I can use less traveled roads or ride during hours the traffic is lower I will. I also will do pull offs if traffic can't pass.

Last edited:

Tony01

Well-Known Member

Gotta send this thing home. The best design is having the clutch on the jackshaft like every motorcycle ever built. CGs and whizzers are set up like that. I don’t know why so many of us with industrial engines (including me) put it on the crankshaft. It may be a trend carried over from minibike or go-kart experience. In the case of the sportsman flyer it has to do with packaging to have the pedal spindle doubling as the jackshaft, which both final chains sharing endpoints.

A clutch on JS accomplishes several things. For one it keeps the bike skinny. Second, the clutch spins slower and doesn’t heat up or wear out as fast. Third, a stock clutch for a slow go kart can be used. To get a good top speed we have to gear higher, and have to mod the clutch to engage higher at the torque max of the engine. Putting it after a primary reduction allows one to run a stock clutch with a lower engagement reducing heat, cost, and effort during replacement.

Then there is the primary drive type. A lot of vehicles without an enclosed primary reduction use a belt, because chains and gears will overheat without lube. Ie- Whizzer (vbelt), huasheng 50cc, the new Surron Ebike (flat toothed belt). Primary chain and clutch heat was a MAJOR problem for me on my 212.

Whizzers also use a vbelt final. I believe this only works with low-torque motors, or higher torque motors under perfect conditions. Problem is the small front pulley with not enough wrap-around. This design allows one to use a standard bicycle rear wheel with brake and freewheel sprocket built in.

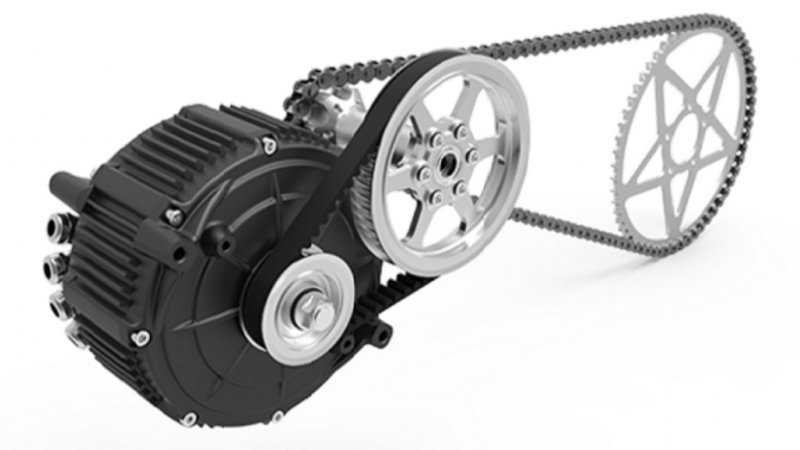

Here’s a couple examples of good designs in my opinion:

msrfan: belt primary, clutch on JS, with final chain drive to not slip under the big motor torque of an 8hp Briggs (300cc?)

Surron ebike drivetrain: high reduction keeps an electric motor revving higher and running most efficiently. Also the jackshaft is concentric with the swingarm pivot so there is no change in chain tension throughout rear travel.

people riding off-road with highly modded surrons tend to snap the belt landing jumps; a chain primary kit is available.

My next build will have a v-belt primary and chain final. I have not yet decided on the clutch but I will start with a typical $30 max torque clutch and go from there. My first setup had a tensioned v-belt clutch which worked well but was incorrectly set up, and the final drive was a disaster before I learned how to do it right and I scrapped the entire drivetrain (I tried using a 16” rim for a sheave, it didn’t work). I plan to figure it out for real next year.

A clutch on JS accomplishes several things. For one it keeps the bike skinny. Second, the clutch spins slower and doesn’t heat up or wear out as fast. Third, a stock clutch for a slow go kart can be used. To get a good top speed we have to gear higher, and have to mod the clutch to engage higher at the torque max of the engine. Putting it after a primary reduction allows one to run a stock clutch with a lower engagement reducing heat, cost, and effort during replacement.

Then there is the primary drive type. A lot of vehicles without an enclosed primary reduction use a belt, because chains and gears will overheat without lube. Ie- Whizzer (vbelt), huasheng 50cc, the new Surron Ebike (flat toothed belt). Primary chain and clutch heat was a MAJOR problem for me on my 212.

Whizzers also use a vbelt final. I believe this only works with low-torque motors, or higher torque motors under perfect conditions. Problem is the small front pulley with not enough wrap-around. This design allows one to use a standard bicycle rear wheel with brake and freewheel sprocket built in.

Here’s a couple examples of good designs in my opinion:

msrfan: belt primary, clutch on JS, with final chain drive to not slip under the big motor torque of an 8hp Briggs (300cc?)

Surron ebike drivetrain: high reduction keeps an electric motor revving higher and running most efficiently. Also the jackshaft is concentric with the swingarm pivot so there is no change in chain tension throughout rear travel.

people riding off-road with highly modded surrons tend to snap the belt landing jumps; a chain primary kit is available.

My next build will have a v-belt primary and chain final. I have not yet decided on the clutch but I will start with a typical $30 max torque clutch and go from there. My first setup had a tensioned v-belt clutch which worked well but was incorrectly set up, and the final drive was a disaster before I learned how to do it right and I scrapped the entire drivetrain (I tried using a 16” rim for a sheave, it didn’t work). I plan to figure it out for real next year.

Last edited: