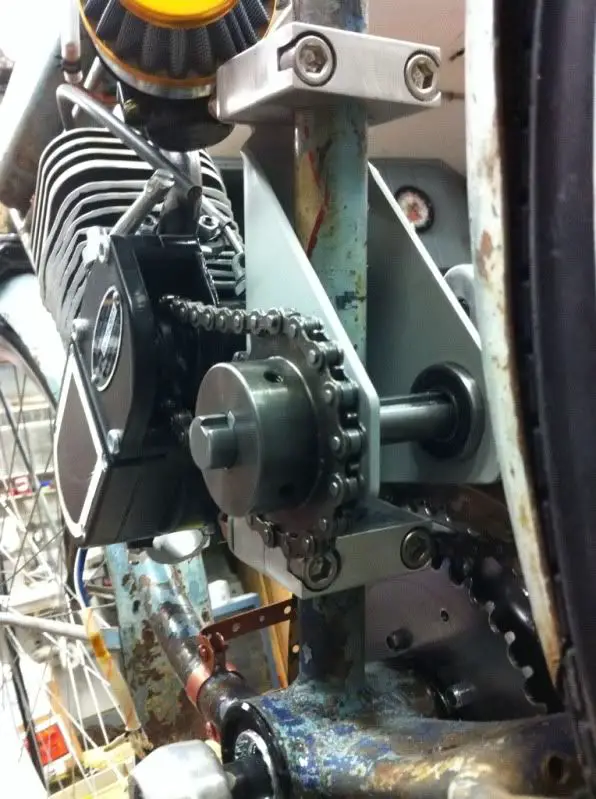

Well, I got a little more done. I picked up an old ladies bike for the bent tubing, and after straightening a bend in the press, making a new bend in the bender, and increasing an existing bend...I ended up with the tube for the front motor mount. It's a 1" tube to match the existing tube on the frame. Instead of centering it in the mount to make for an easy 1/16" shim, I put it all the way forward and will make a tapered shim to wrap around it. I did that so it allows the engine to drop down further once the shim is removed, and I'm hoping the chain will be able to be removed without taking anything apart (we'll see).

Yeah, I forgot to clean the paint off the tube before I tacked it in...I'll deal with that when I do the final welding. On a side note, this frame is welded from the factory, not brazed. That made me happy since I don't have to bother brazing anything that hits a joint. It's been years since I've brazed something.

I installed a rod end on the bottom of the shift kit bracket. I'm going to weld two plates between the tubes there to bolt that rod end to, and use that as the adjuster, rather than the muffler clamp/angle iron/all thread setup that comes with the kit.

You can also see the plug wire going into the stock tank.

I made a mount inside it for the ignition coil. I cut the mount ears off the , and then made a clamp from plumbers strap and welded it inside the tank.

I also found the perfect fitting for the fill port on the brass howitzer shell (gas tank) at menards. I'll solder it in the top of the tank and get a brass cap to go with it. I think I'm going to solder a fuel pickup in the front and rear of the shell, so it'll feed even with low fuel on steep inclines/declines.

I'm not going to start the tank until I decide how far back I'm moving the seat, since it's going to sit on the rack and be right against the seat.

The forks are stretched to fit the hubs now, I'll have to put a string and tape measure on them and be sure it's square, but I need the engine out of the way to do that.

Was thinking of recycling a camping propane tank to use for a compressed air horn...

Was thinking of recycling a camping propane tank to use for a compressed air horn...