You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

No Spark

- Thread starter Kenn'Er

- Start date

First, the magnet will outlast your engine so don't bother replacing it unless it is damaged somehow. Second, If I could make a suggestion that will save you time and money; start by determining why you have no spark instead of just changing parts. How are you checking for spark? To be sure, remove the plug, reconnect it to the plug wire, lay it firmly against the cylinder head fins and walk your bike forward at a good pace while watching the plug electrodes for signs of a spark. Because they are the most popular I'm assuming you have a 2 stroke Chinese engine. If you're using the kit supplied spark plug that could be the source of your problem. Most of us replace it with a better quality item such as the NGK- B-6 HS plug. Champion also makes a replacement, their #811 (L82C) plug.

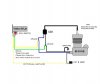

Check your wiring against the diagram below. Disconnect the kill button to make sure it is not giving you a no spark condition. Some are defective. Make sure the plug wire is screwed securely into the CDI and you have a good connection at the plug boot, the plastic part that snaps onto the plug. If you've already done these things and have access to a good ohm meter check your ignition components against the numbers I've attached. Get back to us with the results.

Magneto

Use Low Ohm-Meter Scale About 200 Ohms

1) Check Ohms between BLACK wire and WHITE wire. Reading should be around 2 Ohms

2) Check ohms between BLUE wire and WHITE wire. Should be around 300-400 ohms.

CDI

Use Ohm Meter High Scale About 200-K

1) Positive lead on BLUE wire and Negative lead on BLACK wire should read infinite (no activity)

2) Positive lead on BLACK wire and Negative lead on BLUE wire. Should be about 130-150 K-ohms

3) Positive lead on Spark Plug wire and negative lead on BLUE wire. Should read between 135-155 K-ohms

Switch to Low Scale 20K

4) Measure between Spark Plug wire and and Black lead. Should be about 2.5 - 2.7 K- ohms

Check your wiring against the diagram below. Disconnect the kill button to make sure it is not giving you a no spark condition. Some are defective. Make sure the plug wire is screwed securely into the CDI and you have a good connection at the plug boot, the plastic part that snaps onto the plug. If you've already done these things and have access to a good ohm meter check your ignition components against the numbers I've attached. Get back to us with the results.

Magneto

Use Low Ohm-Meter Scale About 200 Ohms

1) Check Ohms between BLACK wire and WHITE wire. Reading should be around 2 Ohms

2) Check ohms between BLUE wire and WHITE wire. Should be around 300-400 ohms.

CDI

Use Ohm Meter High Scale About 200-K

1) Positive lead on BLUE wire and Negative lead on BLACK wire should read infinite (no activity)

2) Positive lead on BLACK wire and Negative lead on BLUE wire. Should be about 130-150 K-ohms

3) Positive lead on Spark Plug wire and negative lead on BLUE wire. Should read between 135-155 K-ohms

Switch to Low Scale 20K

4) Measure between Spark Plug wire and and Black lead. Should be about 2.5 - 2.7 K- ohms

Attachments

Last edited:

Venice Motor Bikes

Custom Builder / Dealer/Los Angeles

Also, try disconnecting the kill switch & then check for spark!! & make sure the white wire isn't grounding out!!

Never mind... 2door already said that.

Never mind... 2door already said that.

Hi:

Thanks for the great suggestions, i did check the wires and for the magneto for number 1 i got a reading that was off the scale on my meter and for number 2 i got no reading at all. For all of the readings for the cdi they were all around the same as the numbers that you gave me. so with this infromation i figure the the magneto is fried. I also checked the spark b4 i ordered parts using the same method that you explained, and there was no spark. the people that i bought it from used the white wire for a kill switch so i figure that is how the magneto and cdi got fried.

Any suggestions?

Thanks

Kent

Thanks for the great suggestions, i did check the wires and for the magneto for number 1 i got a reading that was off the scale on my meter and for number 2 i got no reading at all. For all of the readings for the cdi they were all around the same as the numbers that you gave me. so with this infromation i figure the the magneto is fried. I also checked the spark b4 i ordered parts using the same method that you explained, and there was no spark. the people that i bought it from used the white wire for a kill switch so i figure that is how the magneto and cdi got fried.

Any suggestions?

Thanks

Kent

Riding Rich

New Member

I once had this happen.

The blue wire should read in the 300K range.

If not break the plastic covering off that side " the blue wire"

Do this carefuly so you don't damage the coils.

Look for an allmost microscopic loose wire under or by the thick copper lead.

Bend the lead upward if you need to.

Burn the varnish off that microscopic wire.

Check it for the 300K resistance.

If it is good do next.

Heat the Copper Lead with a Lighter or soldering iron.

Put a bead of solder on the wire and connect it to the copper lead.

Check the lead if the ohms are 300K + your in buisness.

Forget the white wire.

Connect blue magneto to blue CDI.

Connect Black magneto to black CDI

Smile and go ride you bike.

I had to do this to mine.

The wite wire resistance is like really low set meter to 200 ohms.

The Blue wire has around 340K resistance.

If you don't have resistance at the magneto blue wire and cant fix it as i described above youll need a new one.

Other than that go to the Motorcycle shop and get a new plug wire and boot.

But with a new CDI i doubt thats the problem.

Either way replace the wire and boot.

It's cheap and much better.

The wire just screws into the cdi and boot.

Twist it to change.

Lefty loosey Righty Tighty.

Turn counterclockwise to loosen .

The blue wire should read in the 300K range.

If not break the plastic covering off that side " the blue wire"

Do this carefuly so you don't damage the coils.

Look for an allmost microscopic loose wire under or by the thick copper lead.

Bend the lead upward if you need to.

Burn the varnish off that microscopic wire.

Check it for the 300K resistance.

If it is good do next.

Heat the Copper Lead with a Lighter or soldering iron.

Put a bead of solder on the wire and connect it to the copper lead.

Check the lead if the ohms are 300K + your in buisness.

Forget the white wire.

Connect blue magneto to blue CDI.

Connect Black magneto to black CDI

Smile and go ride you bike.

I had to do this to mine.

The wite wire resistance is like really low set meter to 200 ohms.

The Blue wire has around 340K resistance.

If you don't have resistance at the magneto blue wire and cant fix it as i described above youll need a new one.

Other than that go to the Motorcycle shop and get a new plug wire and boot.

But with a new CDI i doubt thats the problem.

Either way replace the wire and boot.

It's cheap and much better.

The wire just screws into the cdi and boot.

Twist it to change.

Lefty loosey Righty Tighty.

Turn counterclockwise to loosen .

Norman

LORD VADER Moderator

I found that one engine I have if the magnet rotor is on backwards it won't spark. If you take of off turn it over put it back on it works. I wonder if that could be the problem you have? Could have been a rough day at the china engine factory.

I don't know if the other engines will do that cause I mark them before I take them off this one I forgot to mark. I didn't think it would matter on the one I put on backwards but it matters at least this one don't like being on backwards.

I don't know if the other engines will do that cause I mark them before I take them off this one I forgot to mark. I didn't think it would matter on the one I put on backwards but it matters at least this one don't like being on backwards.

Riding Rich

New Member

carpetrugger

New Member

I have the same problem. I checked my CDI and got no readings at all. Checked the mag and only got one reading that being the black to white wire and it was 2.3 When building the bike I installed a kill switch in my headlights case which is attached to the front fork. Instead of using the slip on connectors I sodierd the wires together and used shrink tube.The bike was running fine. I was repacking all the bearings and when removing the front fork I had to disconnect the wires to my kill switch. I got in a hurry taking whe wires apart and didn't want to wait for my sodiering iron to heat up so I melted the old sodier off the wires with my propane torch. After rewiring it I had no spark. Is it possible that I mucked up both the CDI and my mag getting it to hot with the torch?

can you get these spark plugs at like a automotive store or anywhere?

Napa here in florida has them. Though I use the protruded electrode NGK BP series instead of the B6HS. If you decide to use the BP make sure you have clearance. On some motos it may not clear the piston.

awesome thanks guys.... I have spark now but it still won't run, dunno. but then again I just got the bike and have no clue what motor is on it or anything, I don't even know which position the choke lever needs to be to be open... but right now when I try to compression start it it turns over every other try... then the other half of the time it tries to engage but it won't turn over, feels like compression lock and brings the bike to a stop in a hurry... I have no idea how to even get the damn thing started....

sorry for the possible thread jack...

sorry for the possible thread jack...

Last edited:

Riding Rich

New Member

Check your clutch sounds like your clutch mught be slippin a little.

Loosen up the cable some so the clutch arm don't have tension on it.

If it still isnt turning the motor take the clutch cover off and tighten up the flower nut a little. Maybe 1 or 2 turns.

Loosen up the cable some so the clutch arm don't have tension on it.

If it still isnt turning the motor take the clutch cover off and tighten up the flower nut a little. Maybe 1 or 2 turns.

Riding Rich

New Member

The black nut with a star shape there is a little screw in the plate that keeps it from turning. Take off the clutch cover 1st.

Where the small and large gear are at.

Where the small and large gear are at.

After reading all of the many posts on No Spark problems and taking numerous resistance readings on the CDI, the power coil and the pickup coil and comparing them to a number of different opinions about what the readings should be I found myself right where I started; not knowing if I needed a new CDI, magnito, or spark plug. I had no spark right from the get go and I was determined to solve the problem without having to purchase any additional items. Here is what you should do before you decide to buy anything!

1. Make sure your kill switch is not faulty. What I mean is that when the switch is not being pressed, there is an open circuit between the two wires comming out of the switch. This can be checked with a simple continuity meter. Disconnect all kill switch wires and hook the meter leads, one on each wire and your meter should read infinite ohms, now push the switch and you should read close to zero ohms. If this is the case, your kill switch is working fine. Go ahead and connect one of those wires to the engine block. Don't connect the other end just yet - I'll get to that.

2. Unscrew the spark plug wire from the CDI and the boot housing. They will both come apart if you unscrew the wire counter clockwise. They basically screw into a sheet metal screw and make contact with the wire inside the insulation. Now with a good pair of wire cutters of scissors, trim about 1/8 to 1/4 inch off each end and re-attach the wires as tight as you can - be careful not to overtighten and strip the wire, although this is hard to do.

3. Clean off the electrical connector on the spark plug with a wire brush. This is the threaded screw that the boot snaps onto.

4. CUT OFF ALL OF THE CHEAP CONNECTORS ON THE CDI WIRES AND THE ENGINE WIRES!

5. Instead of using the connectors to hook these wires up, use solder and shrink tube. Make sure you know how to solder two wires together. If you're not sure - google it. This would include the kill switch wire.

6. Set the spark plug gap according to your user manual. Usually 0.20-0.35".

7. You can check the spark now by resting the threaded portion of the plug on the engine block (this provides a ground path in the circuit) and spinning the back tire. I'll bet that you have a good spark now.

8. Screw in the plug and off you go.

Most electrical failures are due to poor interconnecting wire. This was the case with my setup - Chances are all of your parts are good - but when you replace one, you will likely get a new part with good connectors and such. Try my tips first before you buy any new parts. And please let me know how you make out.

Good Luck

1. Make sure your kill switch is not faulty. What I mean is that when the switch is not being pressed, there is an open circuit between the two wires comming out of the switch. This can be checked with a simple continuity meter. Disconnect all kill switch wires and hook the meter leads, one on each wire and your meter should read infinite ohms, now push the switch and you should read close to zero ohms. If this is the case, your kill switch is working fine. Go ahead and connect one of those wires to the engine block. Don't connect the other end just yet - I'll get to that.

2. Unscrew the spark plug wire from the CDI and the boot housing. They will both come apart if you unscrew the wire counter clockwise. They basically screw into a sheet metal screw and make contact with the wire inside the insulation. Now with a good pair of wire cutters of scissors, trim about 1/8 to 1/4 inch off each end and re-attach the wires as tight as you can - be careful not to overtighten and strip the wire, although this is hard to do.

3. Clean off the electrical connector on the spark plug with a wire brush. This is the threaded screw that the boot snaps onto.

4. CUT OFF ALL OF THE CHEAP CONNECTORS ON THE CDI WIRES AND THE ENGINE WIRES!

5. Instead of using the connectors to hook these wires up, use solder and shrink tube. Make sure you know how to solder two wires together. If you're not sure - google it. This would include the kill switch wire.

6. Set the spark plug gap according to your user manual. Usually 0.20-0.35".

7. You can check the spark now by resting the threaded portion of the plug on the engine block (this provides a ground path in the circuit) and spinning the back tire. I'll bet that you have a good spark now.

8. Screw in the plug and off you go.

Most electrical failures are due to poor interconnecting wire. This was the case with my setup - Chances are all of your parts are good - but when you replace one, you will likely get a new part with good connectors and such. Try my tips first before you buy any new parts. And please let me know how you make out.

Good Luck