I am a complete noob at this, i am planning my build and i am having a couple issue on understanding how i will start the motor on my boardtrack

the engine is pretty big, predator 212, so i wont need to pedal it whatsoever but would like to have the pedal to start the motor and rest my feet.

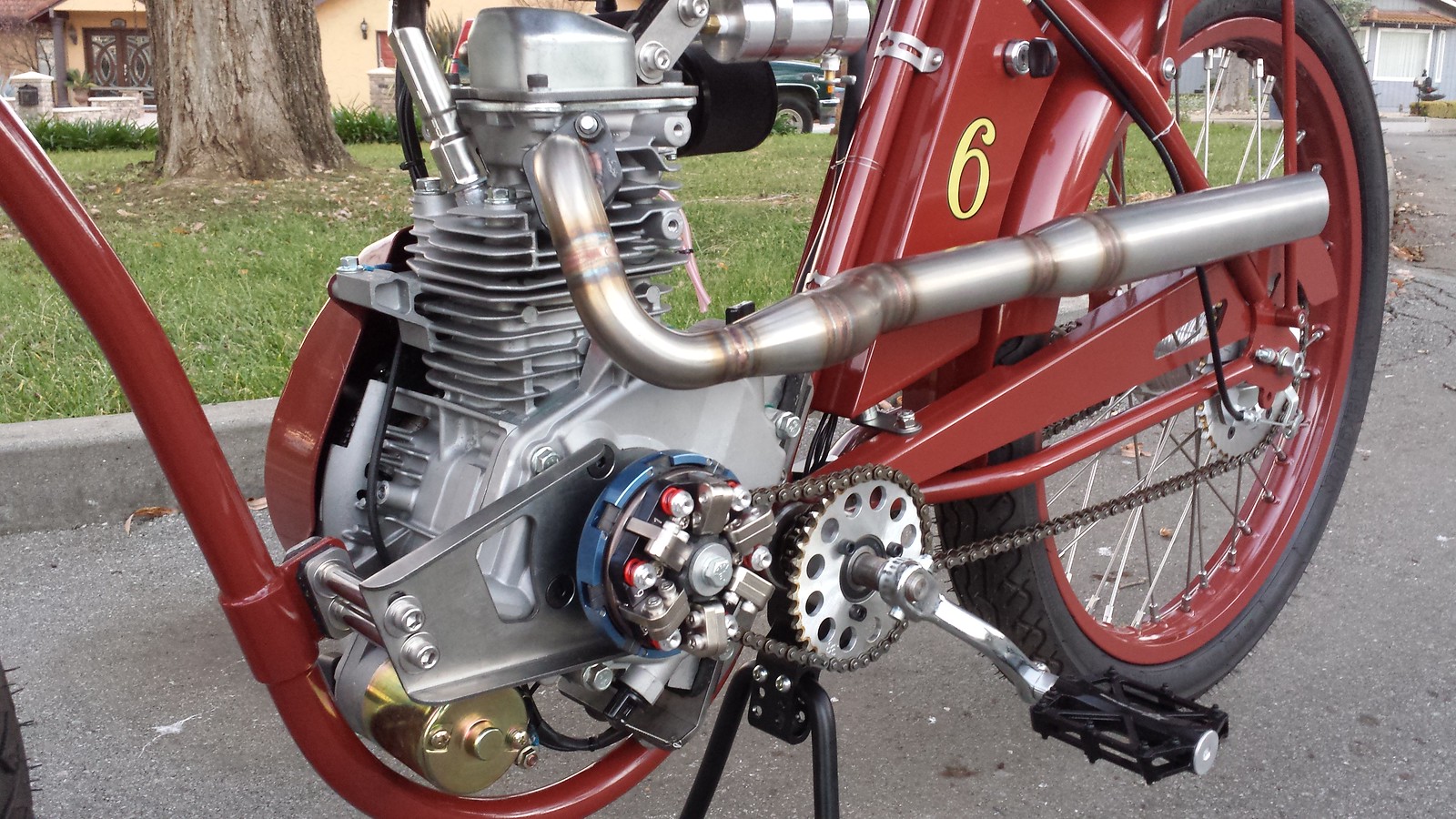

i was wondering if someone can explain what the jackshaft does and how the clutch assembly works, and what would be the best way to start the motor. i dont want a pull start.

thanks for your help, i will post the build here soon , still trying to find a hub and spoke size for my 21" motorcycle wheels. i am having trouble finding someone to help finding compatible parts. lots of people have the answer but few speak.

i need to figure out the wheels first to adjust my fork and frame to suit the width. if anyone know what moped hub could fit my 36 spokes dirt bike wheels or where to find appropriate spokes for whatever hub that would work please let me know..

i am stalled and cant just order hubs without really knowing. money is tight.

cheers!

the engine is pretty big, predator 212, so i wont need to pedal it whatsoever but would like to have the pedal to start the motor and rest my feet.

i was wondering if someone can explain what the jackshaft does and how the clutch assembly works, and what would be the best way to start the motor. i dont want a pull start.

thanks for your help, i will post the build here soon , still trying to find a hub and spoke size for my 21" motorcycle wheels. i am having trouble finding someone to help finding compatible parts. lots of people have the answer but few speak.

i need to figure out the wheels first to adjust my fork and frame to suit the width. if anyone know what moped hub could fit my 36 spokes dirt bike wheels or where to find appropriate spokes for whatever hub that would work please let me know..

i am stalled and cant just order hubs without really knowing. money is tight.

cheers!