Hi folks,

I've been lurking here a bit, gathering info on what kind of engine I could put on my old mountain bike. I can't afford one of the Huasheng/Honda 4-stroke kits right now, and I've heard all kinds of things about the Chinese 2-strokes exploding after a few miles. So when I saw a 3 hp Briggs & Stratton motor on craigslist for $30, I decided to build my own. My goal for this project is to keep the budget under $100.

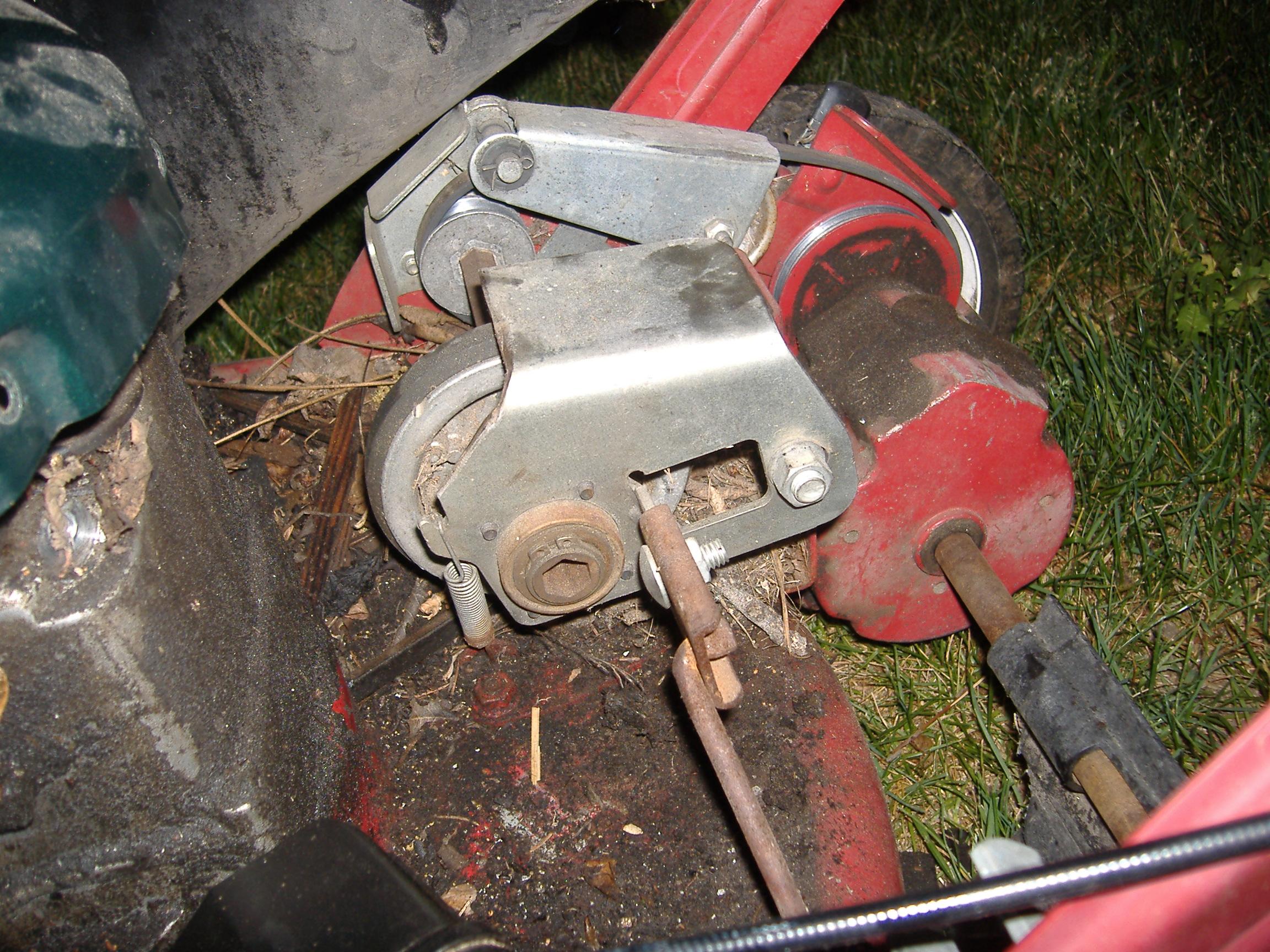

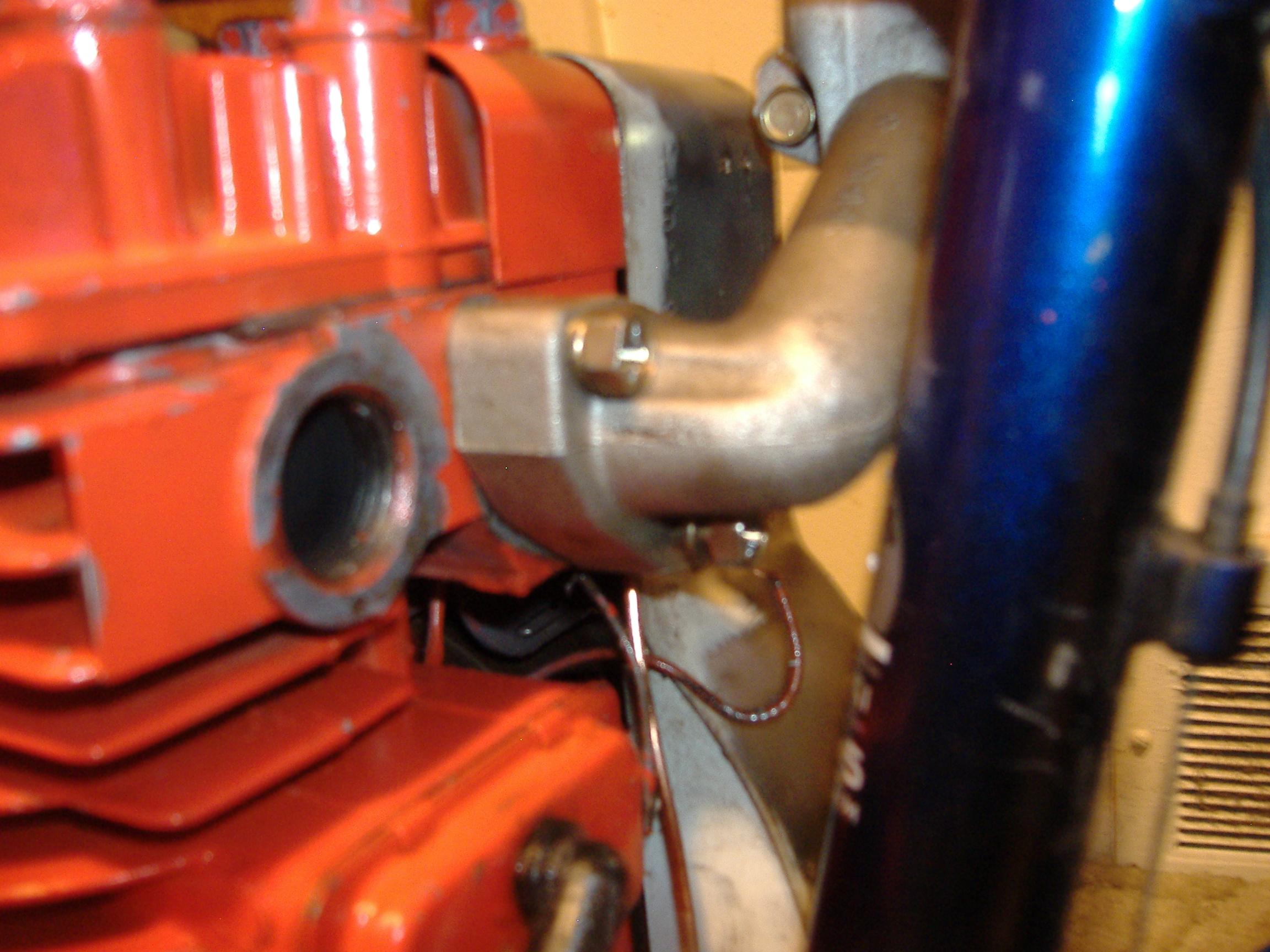

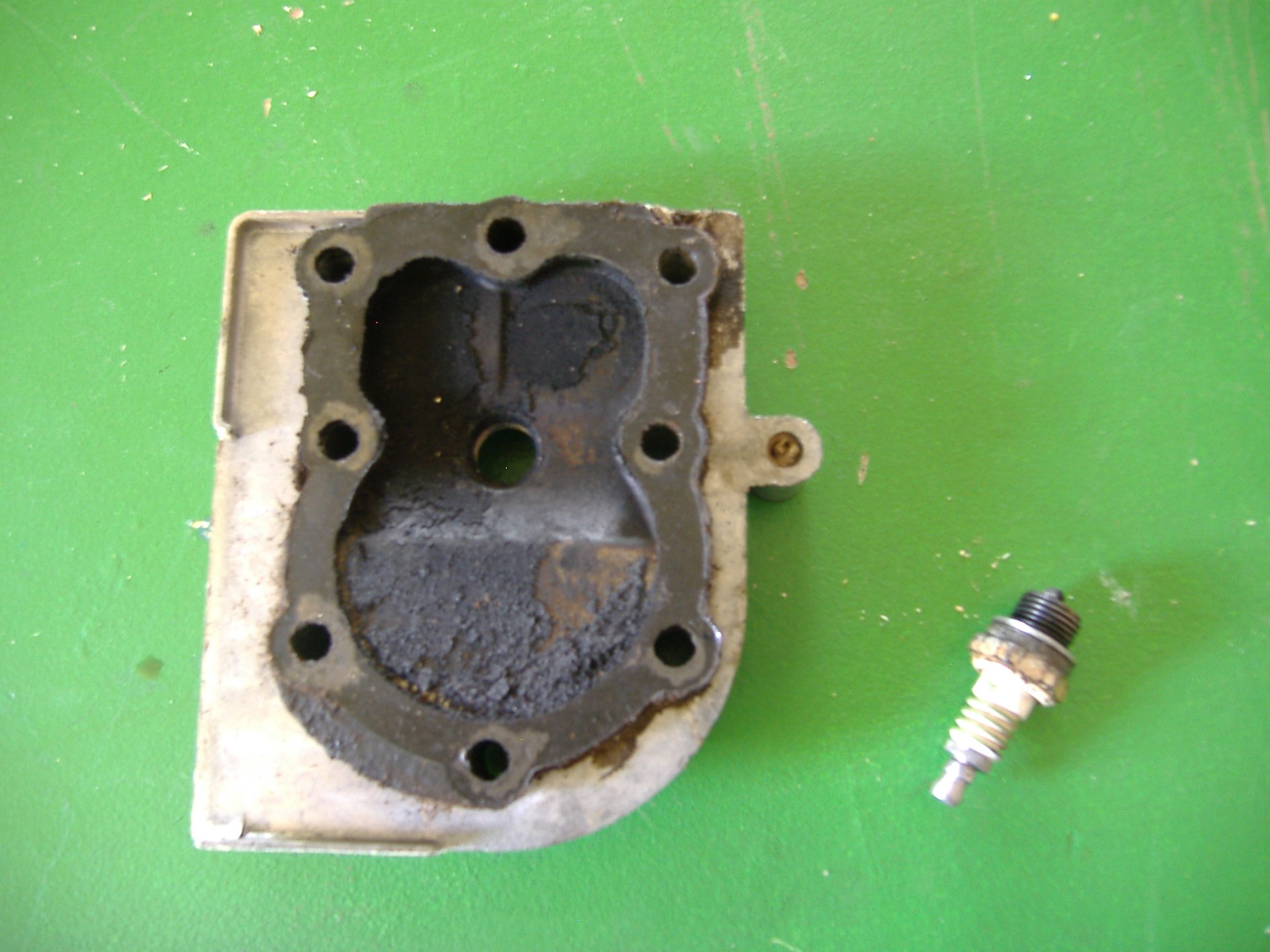

My plan right now is to get the motor mounted in the frame, and figure other stuff out later. The engine doesn't quite fit, so I'm going to cut some notches in the bottom of the engine for clearance, near the bolt holes for mounting the engine. Then I'll make some motor mounts, either by sand-casting them out of aluminum or by borrowing a welder and fabbing them from steel. I'll probably have to re-route the intake and exhaust too, maybe going to a float-type carburetor.

For the transmission, I'm going with a belt drive like a Whizzer, with a smaller wheel rim as the rear pulley. I can either use a centrifugal clutch with a pulley or use an adjustable tensioner to engage or disengage the belt. With a 3.2" engine pulley this will give me a speed of 35 mph at 3,000 rpm. Not the best gear ratio, but maybe I'll add a jackshaft or a gear reduction later.

So, what do you think? Should I go with a centrifugal go-kart clutch or make my own manual friction clutch?

I've been lurking here a bit, gathering info on what kind of engine I could put on my old mountain bike. I can't afford one of the Huasheng/Honda 4-stroke kits right now, and I've heard all kinds of things about the Chinese 2-strokes exploding after a few miles. So when I saw a 3 hp Briggs & Stratton motor on craigslist for $30, I decided to build my own. My goal for this project is to keep the budget under $100.

My plan right now is to get the motor mounted in the frame, and figure other stuff out later. The engine doesn't quite fit, so I'm going to cut some notches in the bottom of the engine for clearance, near the bolt holes for mounting the engine. Then I'll make some motor mounts, either by sand-casting them out of aluminum or by borrowing a welder and fabbing them from steel. I'll probably have to re-route the intake and exhaust too, maybe going to a float-type carburetor.

For the transmission, I'm going with a belt drive like a Whizzer, with a smaller wheel rim as the rear pulley. I can either use a centrifugal clutch with a pulley or use an adjustable tensioner to engage or disengage the belt. With a 3.2" engine pulley this will give me a speed of 35 mph at 3,000 rpm. Not the best gear ratio, but maybe I'll add a jackshaft or a gear reduction later.

So, what do you think? Should I go with a centrifugal go-kart clutch or make my own manual friction clutch?

Attachments

-

719 KB Views: 1,875

-

514.5 KB Views: 1,932

Last edited: