been playing with the idea of machining a new cylinder for a 66cc china 2 stroke.

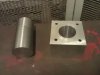

had a cylinder at work to weld up and machine a gouge in the wall and was thinking how much longer an iron sleeve would last. I checked around the shop and found some aluminum blocks large enough to make jugs out of.

idea is this, basically machine an aluminum block to same dims as stock jug except leave a lot more material for a sleeve. it looks to me that if the wall thickness on the factory jugs was a lot thicker you could just bore it out and drop in a sleeve. So if it is just a wall thickness issue then why cant i just make a new jug with a larger outside cylinder dia. to leave enough wall thickness for a sleeve?

if the stud/cylinder wall thickness will be an issue i could always make a spacer/adapter plate to allow for a wider bolt pattern.

-shrug- i havent really looked into it too much yet, figured i must be missing something since it seems simple and i havent heard of anyone doing it yet.

so what am i overlooking?

had a cylinder at work to weld up and machine a gouge in the wall and was thinking how much longer an iron sleeve would last. I checked around the shop and found some aluminum blocks large enough to make jugs out of.

idea is this, basically machine an aluminum block to same dims as stock jug except leave a lot more material for a sleeve. it looks to me that if the wall thickness on the factory jugs was a lot thicker you could just bore it out and drop in a sleeve. So if it is just a wall thickness issue then why cant i just make a new jug with a larger outside cylinder dia. to leave enough wall thickness for a sleeve?

if the stud/cylinder wall thickness will be an issue i could always make a spacer/adapter plate to allow for a wider bolt pattern.

-shrug- i havent really looked into it too much yet, figured i must be missing something since it seems simple and i havent heard of anyone doing it yet.

so what am i overlooking?

I can buy lots of engines, but not yet.

I can buy lots of engines, but not yet.