An idea for those who desire a more hands-on approach to making /

welding up their own MB exhaust flange/ header.

Sometimes the factory exh. flanges just don't hold up.

Your local hardware store likely carries 1/8" thick X 2.5" steel washers.

Most already have a .750" diameter center hole.

There are also 3/16" washers; make sure they're at least Grade 5.

These washers are quite heavy duty and will suit the purpose.

Avoid cad plated soft washers for MIG use.

*Hack, chop, drill your way to a heavy exhaust flange that will support nearly

any diam. tube you need.

Factory exhaust tubing runs 22-23mm [7/8" OD] with approx. .080" wall.

The ones I measured run .750" ID.

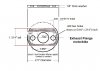

Included is my drawing for a DIY exhaust flange.

The job is easier with calipers, a drill press & cutoff wheel.

To extended the header use 3/4 inch [.750" OD] black plumber pipe - its super heavy duty.

Threaded 3/4" pipe welded to the front half, is ideal to extend the BGF Voodoo pipe (from center nut to rear end).

That heavy 3/4" ID threaded nut can save a lot of assembly time.

B Method: trace out an exhaust gasket & proceed to *H/C/D.

welding up their own MB exhaust flange/ header.

Sometimes the factory exh. flanges just don't hold up.

Your local hardware store likely carries 1/8" thick X 2.5" steel washers.

Most already have a .750" diameter center hole.

There are also 3/16" washers; make sure they're at least Grade 5.

These washers are quite heavy duty and will suit the purpose.

Avoid cad plated soft washers for MIG use.

*Hack, chop, drill your way to a heavy exhaust flange that will support nearly

any diam. tube you need.

Factory exhaust tubing runs 22-23mm [7/8" OD] with approx. .080" wall.

The ones I measured run .750" ID.

Included is my drawing for a DIY exhaust flange.

The job is easier with calipers, a drill press & cutoff wheel.

To extended the header use 3/4 inch [.750" OD] black plumber pipe - its super heavy duty.

Threaded 3/4" pipe welded to the front half, is ideal to extend the BGF Voodoo pipe (from center nut to rear end).

That heavy 3/4" ID threaded nut can save a lot of assembly time.

B Method: trace out an exhaust gasket & proceed to *H/C/D.

Attachments

-

118.3 KB Views: 386

-

100.2 KB Views: 319

-

161.9 KB Views: 423

Last edited: