Crazy Horse

Dealer

This is how I Stretch / Convert most styles of StingRay Choppers or Clone OCC Chopper into a Schwinn XL Chopper or the Schwinn XXL Chopper style build.

Here's a Parts & Tools list that you'll need to get started:

Tools and Equipment:

For cutting the frame up use a hack saw, reciprocating saw ( Sawzall ), angle grinder, or steel chopsaw for the straightest cut.

For welding the frame back together, a welding shop or your own personal welder.

I use 1-3/4" round steel tubing for the top tube, and downtube from headtube.

I'd suggest sleeving slightly smaller steel tubing inside the 1-3/4" steel tubing for extra strength for the new extended steel tubing that you'll be using on the top tube which runs from the headtube to the rear triangle and the for the new extended tubing which you'll be using on the steel tube which runs from the headtube to the bottom bracket also known to some builders as the pedalcrank.

I use 1-1/2" X 4" X 16-gauge rectangular steel tubing for the bottom tube.

You can build this Stretched Chopper as an XL Chopper with a 22" bottom tube, or you can build this Stretched Chopper as an XXL Chopper with a 30" bottom tube.

Notice: Remember your leg length should determine the amount of Stretch you decide on, 5-7-inches to 6-feet tall you'd want to only add a 22-inch bottom tube. 6-feet or taller go for the XXL Stretch Chopper with bottom tube measurement of 30-inches.

You also need 2 stock 20-inch StingRay or OCC Style Chopper Bicycles to chop for your build. Or just one if you can source the 1-3/4" round steel tubing.

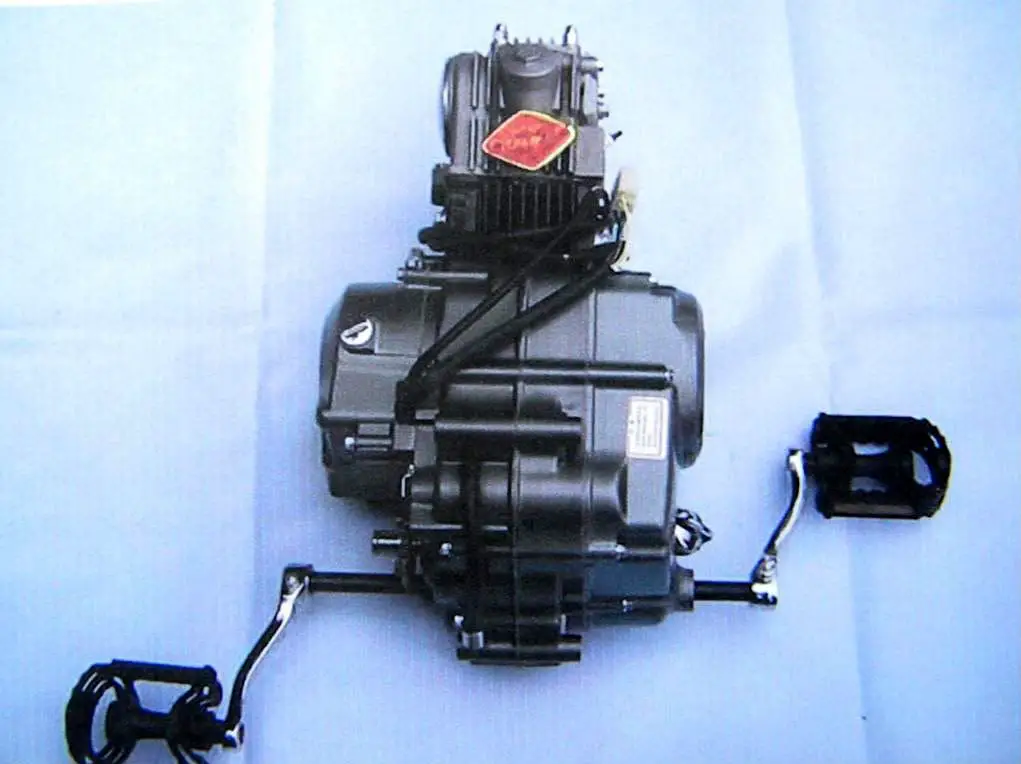

I prefer using the 1-1/2" X 4" X 16-Gauge Rectangular Steel Tubing for the bottom tube so that I can easily add a Honda crf50 or Pitbike, and or kids ATV ( 49cc - 125cc ), engine's to the square / Rectangular bottom tube.

I'll be posting a few how to pictures showing you where I cut my frames, and other pictures as I go through the build.

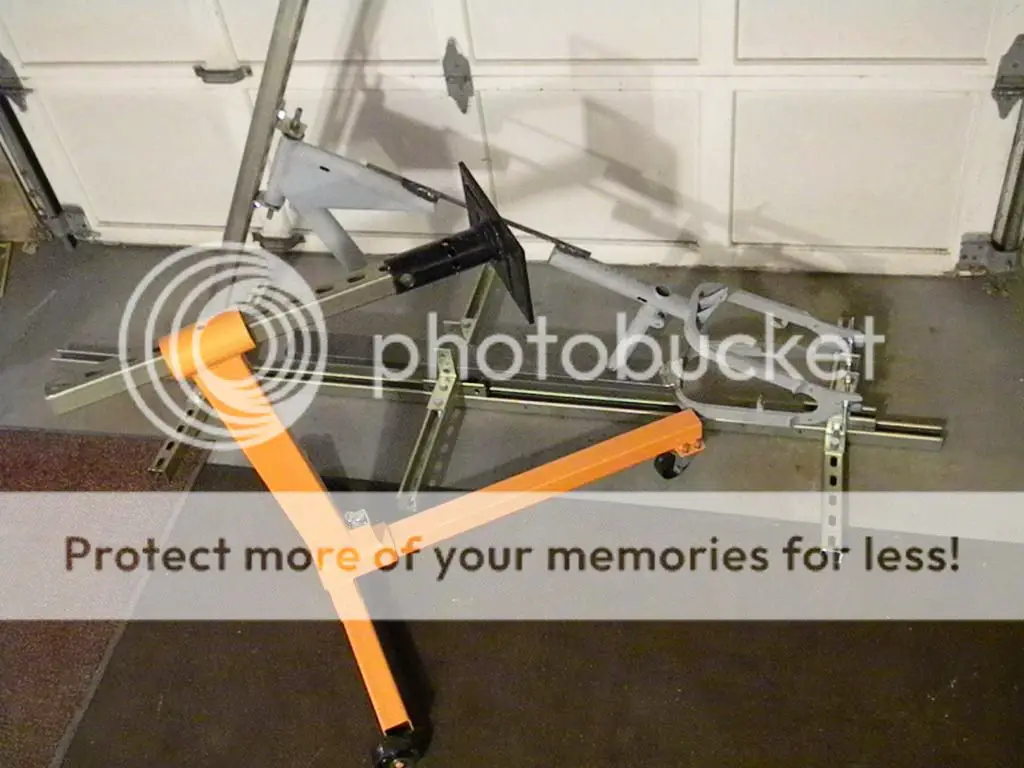

Here's what a stock / regular sized 20-inch StingRay Chopper frame with a 14.50-inch bottom tube looks like next to a XXL Chopper with bottom tube measurement of 30-inches . Notice the Xl Chopper Bicycles have a bottom tube measurement of 22.50-inches.

Here's what the Round Steel Tubing and Rectangular Steel Tubing I use looks like.

This what you'll be aiming for if you go for the 30-inch stretch for a XXL Chopper.

To be continued soon....I have to upload pictures of where I cut the frame, then I can post them.

Here's a Parts & Tools list that you'll need to get started:

Tools and Equipment:

For cutting the frame up use a hack saw, reciprocating saw ( Sawzall ), angle grinder, or steel chopsaw for the straightest cut.

For welding the frame back together, a welding shop or your own personal welder.

I use 1-3/4" round steel tubing for the top tube, and downtube from headtube.

I'd suggest sleeving slightly smaller steel tubing inside the 1-3/4" steel tubing for extra strength for the new extended steel tubing that you'll be using on the top tube which runs from the headtube to the rear triangle and the for the new extended tubing which you'll be using on the steel tube which runs from the headtube to the bottom bracket also known to some builders as the pedalcrank.

I use 1-1/2" X 4" X 16-gauge rectangular steel tubing for the bottom tube.

You can build this Stretched Chopper as an XL Chopper with a 22" bottom tube, or you can build this Stretched Chopper as an XXL Chopper with a 30" bottom tube.

Notice: Remember your leg length should determine the amount of Stretch you decide on, 5-7-inches to 6-feet tall you'd want to only add a 22-inch bottom tube. 6-feet or taller go for the XXL Stretch Chopper with bottom tube measurement of 30-inches.

You also need 2 stock 20-inch StingRay or OCC Style Chopper Bicycles to chop for your build. Or just one if you can source the 1-3/4" round steel tubing.

I prefer using the 1-1/2" X 4" X 16-Gauge Rectangular Steel Tubing for the bottom tube so that I can easily add a Honda crf50 or Pitbike, and or kids ATV ( 49cc - 125cc ), engine's to the square / Rectangular bottom tube.

I'll be posting a few how to pictures showing you where I cut my frames, and other pictures as I go through the build.

Here's what a stock / regular sized 20-inch StingRay Chopper frame with a 14.50-inch bottom tube looks like next to a XXL Chopper with bottom tube measurement of 30-inches . Notice the Xl Chopper Bicycles have a bottom tube measurement of 22.50-inches.

Here's what the Round Steel Tubing and Rectangular Steel Tubing I use looks like.

This what you'll be aiming for if you go for the 30-inch stretch for a XXL Chopper.

To be continued soon....I have to upload pictures of where I cut the frame, then I can post them.

Last edited: