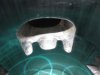

well i might to edit lol. what do u think t? have you seen ports at diff heights ???

ex ports yes but i think im perhaps barking up the wrong tree.

i will need to think about it more as im in the middle of cyl reed work w is different »when discusing yours. i will watch anyway as i have got this far in 8 months.

i feel uselessly unable to get help sometimes. i wish to broaden the GP MX minded thinking. its very hard sometimes without purchasing the sweet ass books available.

please pardon my candid 10 minute old ideas if it is not working.

ex ports yes but i think im perhaps barking up the wrong tree.

i will need to think about it more as im in the middle of cyl reed work w is different »when discusing yours. i will watch anyway as i have got this far in 8 months.

i feel uselessly unable to get help sometimes. i wish to broaden the GP MX minded thinking. its very hard sometimes without purchasing the sweet ass books available.

please pardon my candid 10 minute old ideas if it is not working.

Last edited: