deacon

minor bike philosopher

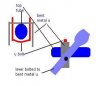

I'm pretty sure everyone has seen my design for mounting a ryobi engine The two rails that attach to the engine, the front harp, and the scissor hinges to keep it in line.

Now I wish to add this bit of information. How to mount it to the bike with no damage to the bike. No drilling or even scratches if you are careful. So here it is...

Engine to be rear mount friction drive

New parts added to old design

The rear mount harp secured with 1/4 double nuts and thread lock.

A par of hardware 6" "L" brackets make up the top of this harp. The lower bracket has to be cut off an inch or so to bring it in line with the axle width. The top one is not cut as the henge will rest on it.

The two side drops are used to secure the mount. The lowest hole is used for the brace that attaches to the bike's accesory hole above the axle or to the axle itself depending on whether or not there is an accessory hole.

The second brace runs from the top hole in the "L" bracket to the frame of the bike. It is secured with a pipe clamp bent so that it wraps around the bike frame and then bolts through the brace.

At this point our standard engine mount is attached to the frame with a henge that bolts to the top of the harp. The engine swings forward onto the tire. Standard springs and turnbuckles ect.

The motor raises and lowers by a lever attached to the bikes from near the handlebars.

The throttle is also part of this mechanism.... This arrangement will in no way change the bike and will be 100% removeable. All parts that are attached to the bike will have inner tube glued to them where they meet the bike frame.

This assembly will be secured to the bike with hose clamps to avoid any scratches wrap the bike tube with tape.

Now I wish to add this bit of information. How to mount it to the bike with no damage to the bike. No drilling or even scratches if you are careful. So here it is...

Engine to be rear mount friction drive

New parts added to old design

The rear mount harp secured with 1/4 double nuts and thread lock.

A par of hardware 6" "L" brackets make up the top of this harp. The lower bracket has to be cut off an inch or so to bring it in line with the axle width. The top one is not cut as the henge will rest on it.

The two side drops are used to secure the mount. The lowest hole is used for the brace that attaches to the bike's accesory hole above the axle or to the axle itself depending on whether or not there is an accessory hole.

The second brace runs from the top hole in the "L" bracket to the frame of the bike. It is secured with a pipe clamp bent so that it wraps around the bike frame and then bolts through the brace.

At this point our standard engine mount is attached to the frame with a henge that bolts to the top of the harp. The engine swings forward onto the tire. Standard springs and turnbuckles ect.

The motor raises and lowers by a lever attached to the bikes from near the handlebars.

The throttle is also part of this mechanism.... This arrangement will in no way change the bike and will be 100% removeable. All parts that are attached to the bike will have inner tube glued to them where they meet the bike frame.

This assembly will be secured to the bike with hose clamps to avoid any scratches wrap the bike tube with tape.