SoSauty

New Member

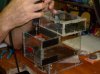

August, time to vamp up our race bikes! The E-crowd is talking up Sept15 as ‘the world championship’ of motorized bikes and there's Oct race at Grange as well. I even heard there was some crazy guy driving down from Michigan. So, a day to build, a day to post, here goes:

For me, running mid-pack with a tire just in front, someone else’s tire under an elbow, is more fun than leading a race if out in front alone. So I’m bumping this mid-size 9-Continental 2806 to its’ limit (maybe beyond); gonna chase me some peppy 2 strokers.

http://www.ebikes.ca/store/store_motors.php

Issues: Replaced the dead headset and bouncy pogo forks with CaneCreek and RockShox forks on sale, $25 & $110. The fork was still too springy so set the lockout halfway; works. Also upgraded the mechanical front disk brake with a sweet ballbearing activated Avid B5.

For me, running mid-pack with a tire just in front, someone else’s tire under an elbow, is more fun than leading a race if out in front alone. So I’m bumping this mid-size 9-Continental 2806 to its’ limit (maybe beyond); gonna chase me some peppy 2 strokers.

http://www.ebikes.ca/store/store_motors.php

Issues: Replaced the dead headset and bouncy pogo forks with CaneCreek and RockShox forks on sale, $25 & $110. The fork was still too springy so set the lockout halfway; works. Also upgraded the mechanical front disk brake with a sweet ballbearing activated Avid B5.

Attachments

Last edited: