You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1900's Clone

- Thread starter cyclone

- Start date

eDJ

Member

This is something I posted to awhile back with making a retro replica.

We were talking Point Beach Schwinn's a few months back.

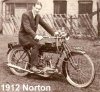

I find plenty of people building the old speedway & board track racers

but the idea of having a tricked out 1900's bike is quite intriguing.

Up until a couple months ago there were plenty of old springer and girter

bicycle front forks from original 1940 & 50 bicycles. They were expensive enough then but they were originals. I'm guessing with the economic downturn they fear not getting the auction bids they want.

But I've gone to the Public Library to look at many of the old Harley & Indian

bikes of that period with pedals.

As I look at your frame.....I seem to remember Norman welding bolts with blue truck suspension bushings to mount the motor to. On that bottom extension plate such a weld up of a piece of frame to the plate could establish the front

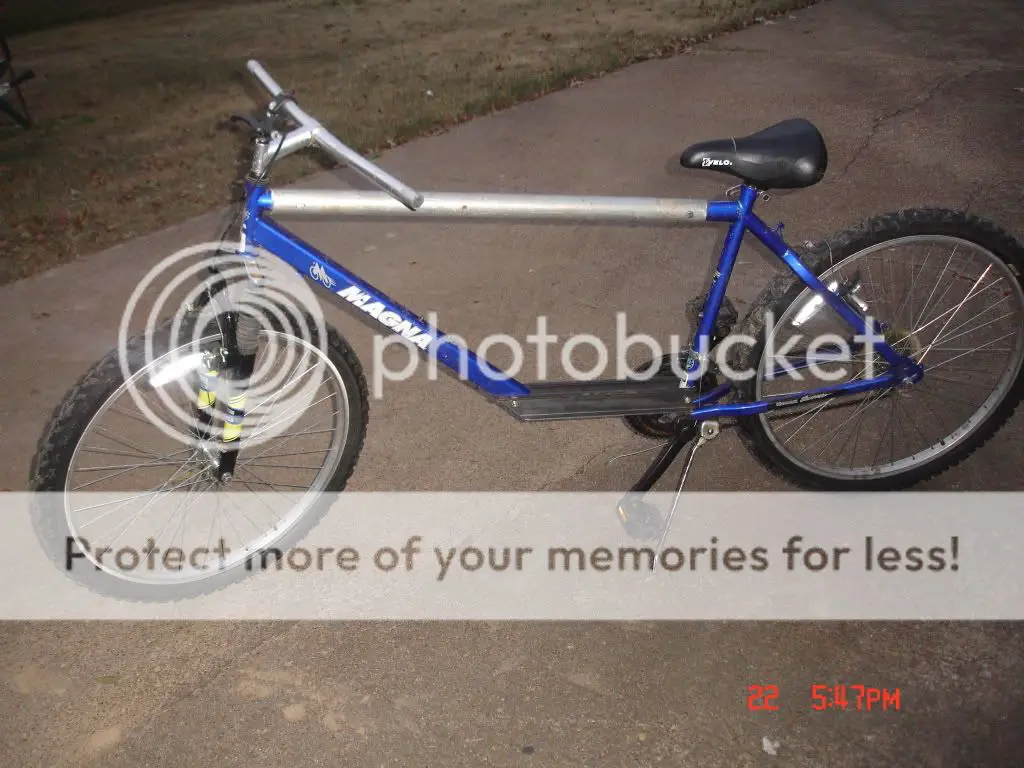

engine mount. But the channel extension you bolted up above the pedal crank housing is an interesting solution. I was only considering an extension of 6 to 8 inches at the most. The first photo was what I mocked up to visualize such a basic build from a Point Beach.

Were you thinking of using a Chinese motor, a Briggs, or Honda ? Harbour Freight now has a motor on sale for $100 which could be used with a centruigul clutch. They are 6.5 hp limit 1 w/cupon. I've estimated the materials I would use would cost $500+ for my build.

We were talking Point Beach Schwinn's a few months back.

I find plenty of people building the old speedway & board track racers

but the idea of having a tricked out 1900's bike is quite intriguing.

Up until a couple months ago there were plenty of old springer and girter

bicycle front forks from original 1940 & 50 bicycles. They were expensive enough then but they were originals. I'm guessing with the economic downturn they fear not getting the auction bids they want.

But I've gone to the Public Library to look at many of the old Harley & Indian

bikes of that period with pedals.

As I look at your frame.....I seem to remember Norman welding bolts with blue truck suspension bushings to mount the motor to. On that bottom extension plate such a weld up of a piece of frame to the plate could establish the front

engine mount. But the channel extension you bolted up above the pedal crank housing is an interesting solution. I was only considering an extension of 6 to 8 inches at the most. The first photo was what I mocked up to visualize such a basic build from a Point Beach.

Were you thinking of using a Chinese motor, a Briggs, or Honda ? Harbour Freight now has a motor on sale for $100 which could be used with a centruigul clutch. They are 6.5 hp limit 1 w/cupon. I've estimated the materials I would use would cost $500+ for my build.

Attachments

Last edited:

I was given a 3.5hp edger motor that runs. The frame was bought in a thrift store. I set on the bike, and 14" was as far as I could reach comfortably. I just found a Yazoo mower with a jackshaft set up for v-belt to chain. So far I have about $40 invested, and about 10 hrs. May have to get a new centrifical clutch. I too have been looking at the early teens motocycles. Lots of frame ideas in vintage motorcycle books. Good Luck!!!!!

xPosTech

The Old Master Motorized Bicycle Builder

<snip>

Were you thinking of using a Chinese motor, a Briggs, or Honda ? Harbour Freight now has a motor on sale for $100 which could be used with a centruigul clutch. They are 6.5 hp limit 1 w/cupon. I've estimated the materials I would use would cost $500+ for my build.

You have a coupon for a 6.5 HP motor? The best I can come up with is $129.99 w/15% off coupon $110.49. I've looked through my emails etc. but no item specific coupon for that motor.

If you have that coupon could you post it? I posted a 15% Off coupon here.

Thanks

Ted

eDJ

Member

xPosTech,

Yeah, Thursday 19'th the HF ad came in my weekend paper in the mail box.

This little paper contains grocery store ad's, Fast Food cupons, weekend events etc. I just happened to notice that motor is $99 dollars with the cupon.

Harbor Freight Tools - Quality Tools at the Lowest Prices

The cupon is good for 1 motor only. (and it says you can't duplicate it) But I'll post a copy for ya. If you have some blank news print paper and a good ink jet printer ya might just pull it off. Tear the edges of the cupon like you tore it out with your fingers instead of scissors and it may pass for an original. Art supply stores or perhaps even WalMart's art supplies sell 8 1/2 x 11 news print paper tablets for sketching for cheap.

As far as the engine, the steel cylinder liner, low oil pressure shut off, and ball bearing chrank indicate some quality features. 34 lbs is probably going to

require some frame reinforcement though, and a sturdy chain, gear, and rim set up to handle the motor's power.

Yeah, Thursday 19'th the HF ad came in my weekend paper in the mail box.

This little paper contains grocery store ad's, Fast Food cupons, weekend events etc. I just happened to notice that motor is $99 dollars with the cupon.

Harbor Freight Tools - Quality Tools at the Lowest Prices

The cupon is good for 1 motor only. (and it says you can't duplicate it) But I'll post a copy for ya. If you have some blank news print paper and a good ink jet printer ya might just pull it off. Tear the edges of the cupon like you tore it out with your fingers instead of scissors and it may pass for an original. Art supply stores or perhaps even WalMart's art supplies sell 8 1/2 x 11 news print paper tablets for sketching for cheap.

As far as the engine, the steel cylinder liner, low oil pressure shut off, and ball bearing chrank indicate some quality features. 34 lbs is probably going to

require some frame reinforcement though, and a sturdy chain, gear, and rim set up to handle the motor's power.

Is that thing held together with bolts!!! Yikes.

No kidding...SCARY. Dude, please don't leave it like that...those bolts, especially the ones on the bottom brackets are going to shear off or pull out of frame. Weld that sucker if at all possible. If you insist on taking the risk and using bolts than at least use 3/8" bolts with large washers and locking nuts and by all means double up each location.

If you haven't riden one of these motorized bicycles yet let me tell you it is a harsh ride. You WILL hit unseen potholes at 30 mph that will jar your fillings loose trust me we have all done it. You don't want your bike snapping in half at that speed you will be eating pavement.

eDJ

Member

Ok, I took two scans which should cover an 8 1/2 x 11 sheet. HF 1.jpg is the

side with the motor cupon you need. But you'll have to print the back of the sheet and HF 2.jpg is the back exactly as it would look. So if you can print both sides the finished print cupon should actually measure 1 3/4 high by 1 7/8 wide.

If you've seen Harbor's printed cupon ad's you should have an idea about the

tone the paper should be.

The cupon is folded across just above the $99.99 in red so the top folds down

toward the bottom. With this fold it will look just like it came out of the ad.

You'll have to blow these images up to where they print out at 8 1/2 x 11 on your printer. These images are 50% of their actual size so I could upload them. With your ink printer's software should allow you to double their size for the print set up so they will print the 8 1/2 x 11 or however you wish to do it. (I don't know how skillful you are at doing this stuff)

If you need, get someone to help ya, and good luck at HF when you give them the cupon. If you catch them busy that would probably be a good time to have the cupon and cash in hand to go into the line.

side with the motor cupon you need. But you'll have to print the back of the sheet and HF 2.jpg is the back exactly as it would look. So if you can print both sides the finished print cupon should actually measure 1 3/4 high by 1 7/8 wide.

If you've seen Harbor's printed cupon ad's you should have an idea about the

tone the paper should be.

The cupon is folded across just above the $99.99 in red so the top folds down

toward the bottom. With this fold it will look just like it came out of the ad.

You'll have to blow these images up to where they print out at 8 1/2 x 11 on your printer. These images are 50% of their actual size so I could upload them. With your ink printer's software should allow you to double their size for the print set up so they will print the 8 1/2 x 11 or however you wish to do it. (I don't know how skillful you are at doing this stuff)

If you need, get someone to help ya, and good luck at HF when you give them the cupon. If you catch them busy that would probably be a good time to have the cupon and cash in hand to go into the line.

Attachments

eDJ

Member

There are several talented welders around where I live. One does airframe welding with small gas torches. (real precision work) He drills a small hole on the low side of tube about 1/4 inch back from the weld before making the weld.

He showed me something called a "hydrogen weld" he likes for some reason. I don't know which rod stock he uses with it but the welds are said to be strong and enduring.

Harbor Freight now has that Fluxed Wire fed welder on sale for $99.99 also.

#98871 ( I don't think it requires a bottle of Co2 )

The Gas Welding acessories kit is on sale also for $94.99. You'll have to get tanks of gas to use from a supplier. Made by Chicago Electric and normally $130.00.

Depending on what someone would want to charge to weld for you you may

find this an alternative. Depending on how small of tanks of gas you can get too for the gas welder. But if you get into something with building 1900's replica motorcycles and dress them out to look vintage it may be worth the investment if you can. Harbor even has some inexpensive paint spray stuff too. This stuff kinda goes fads with the public, but if you had a Board Track bike and a 1900's motorcycle replica to ride around on and people showed interest you could consider building a few to offer for sale. (as used stuff)

He showed me something called a "hydrogen weld" he likes for some reason. I don't know which rod stock he uses with it but the welds are said to be strong and enduring.

Harbor Freight now has that Fluxed Wire fed welder on sale for $99.99 also.

#98871 ( I don't think it requires a bottle of Co2 )

The Gas Welding acessories kit is on sale also for $94.99. You'll have to get tanks of gas to use from a supplier. Made by Chicago Electric and normally $130.00.

Depending on what someone would want to charge to weld for you you may

find this an alternative. Depending on how small of tanks of gas you can get too for the gas welder. But if you get into something with building 1900's replica motorcycles and dress them out to look vintage it may be worth the investment if you can. Harbor even has some inexpensive paint spray stuff too. This stuff kinda goes fads with the public, but if you had a Board Track bike and a 1900's motorcycle replica to ride around on and people showed interest you could consider building a few to offer for sale. (as used stuff)

Humpty bikey

While I know your intentions are good the project bike frame in the pics will never work. The first thing is that you cannot weld aluminum and steel together. Even if it was all aluminum the entire frame would have to be heat treated after welding or else the welds will fail. Welding dissimilar aluminum alloys is also problematic. Even a highly trained welder with the best equipment would not attempt to make this frame a reality.

But you can achieve what you wish perhaps by brazing although you will have to use steel, which is a better choice for the type of weight you are proposing to throw on there in the form of a motor, there is info on that method here: Braze Your Own Bicycle Frame.

Good luck and be safe, not sorry.

I haven't welded since high school.Mainly oxy/acet with a little arc. What is the prefered method of welding bike frames? I also will have to buy or rent welding equipment.

While I know your intentions are good the project bike frame in the pics will never work. The first thing is that you cannot weld aluminum and steel together. Even if it was all aluminum the entire frame would have to be heat treated after welding or else the welds will fail. Welding dissimilar aluminum alloys is also problematic. Even a highly trained welder with the best equipment would not attempt to make this frame a reality.

But you can achieve what you wish perhaps by brazing although you will have to use steel, which is a better choice for the type of weight you are proposing to throw on there in the form of a motor, there is info on that method here: Braze Your Own Bicycle Frame.

Good luck and be safe, not sorry.

xPosTech

The Old Master Motorized Bicycle Builder

<snip>

You'll have to blow these images up to where they print out at 8 1/2 x 11 on your printer. These images are 50% of their actual size so I could upload them. With your ink printer's software should allow you to double their size for the print set up so they will print the 8 1/2 x 11 or however you wish to do it. (I don't know how skillful you are at doing this stuff)

If you need, get someone to help ya, and good luck at HF when you give them the cupon. If you catch them busy that would probably be a good time to have the cupon and cash in hand to go into the line.

Thanks eDJ

On the printer - I used my inkjet so seldom that whenever I wanted to print color I would have to buy cartridges. The ones in the printer would dry up between jobs.

I kept my eyes open and found a Konica Magicolor 2630 DL ($70 @ Goodwill with my discounts) that prints beautiful 2400 DPI color. It came with an ethernet adapter so I use it on my LAN. I sold the HP to a friend for $40.

I'm an ex Houston Post (newspaper) computer tech. I tell everybody via my user name. No, I don't have any trouble printing.

On the coupon - With the way they treat me (and I'm sure all repeat customers - at least this store/manager) all I'll need is the coupon number under the bar code. In the instructions for printing out coupons on their website (somewhere) it says if you can't print the barcode legibly or completely, make sure the number is man-readable. They use the same number for all who use the coupon, otherwise the logistics would overwhelm their servers.

He wrote me a raincheck for the coupon which I posted - they didn't have the motor in stock

I'm one of those "I want what I want when I want it" types. Sometimes I think my impulse buying at HF pays their light bill. I really should make out a list before I go and only get the stuff I want. Make that only what I need.

Shoot - want . . . need . . . same thing, huh?

Ted

Bikeguy Joe

Godfather of Motorized Bicycles

Re: Humpty bikey

Several good points.

You cannot even rivet with dis-similar metals or use steel bolts through aluminum without causing problems.

Maybe use that bike for a conceptual model?

While I know your intentions are good the project bike frame in the pics will never work. The first thing is that you cannot weld aluminum and steel together. Even if it was all aluminum the entire frame would have to be heat treated after welding or else the welds will fail. Welding dissimilar aluminum alloys is also problematic. Even a highly trained welder with the best equipment would not attempt to make this frame a reality.

But you can achieve what you wish perhaps by brazing although you will have to use steel, which is a better choice for the type of weight you are proposing to throw on there in the form of a motor, there is info on that method here: Braze Your Own Bicycle Frame.

Good luck and be safe, not sorry.

Several good points.

You cannot even rivet with dis-similar metals or use steel bolts through aluminum without causing problems.

Maybe use that bike for a conceptual model?

eDJ

Member

I've got three steel 10 spd frames laid by now to work with. (2 26" and 1 24") I've been looking at them for months and been kinda stumpted on conecting the diagonal tube to get the angle right.....just to extend the frame 6 to 8 inches.

I like cyclone's idea as it is a fresh approach and would lend a mounting platform

for other types of motors and still buy room for the pedals to rotate. I'm wondering about a second tube under the upper one to lend more structural strength to this extension.

Being all steel, the welding and bracing may be accomplished easily enough.

But, I'd still want to use some sort of spring suspension forks on the front

of an extended frame bike.

I like cyclone's idea as it is a fresh approach and would lend a mounting platform

for other types of motors and still buy room for the pedals to rotate. I'm wondering about a second tube under the upper one to lend more structural strength to this extension.

Being all steel, the welding and bracing may be accomplished easily enough.

But, I'd still want to use some sort of spring suspension forks on the front

of an extended frame bike.