Got some goodies on the way and got my Rocket CDI today in the mail, I'll install it and see how it goes after I put my engine back together so I can get a "stock" baseline before I duplicate it and upgrade some of the resistors to a higher watt rating and get some different caps & a 10 turn precision pot to change the timing curve.

For a carb, I went with the Tillotson HS254B since it has the same 21mm bore with a 19mm venturi. I also got some aluminum bar stock coming in so I can make a manifold adapter and possibly design a reed box, I may need some more bar stock for the reed box depending on the design I come up with and what reed cage will work best. I'm thinking the GY6 scooter reeds will work with the Tilly carb I ordered, then mill the intake side of the cylinder down to mount at the intake port similar to the Arrow setup, then buy another set of cases or bottom end with a 40mm crank to cut an opening on for a true case inducted setup. With the Tilly or Walbro floatless type carbs, we're not limited to runnnig them completely side draft so it will be possible to mount it at a 45 degree down draft eliminating any bends in the intake tract which would offer a more compact high performance induction system for bikes like mine with limited frame space.

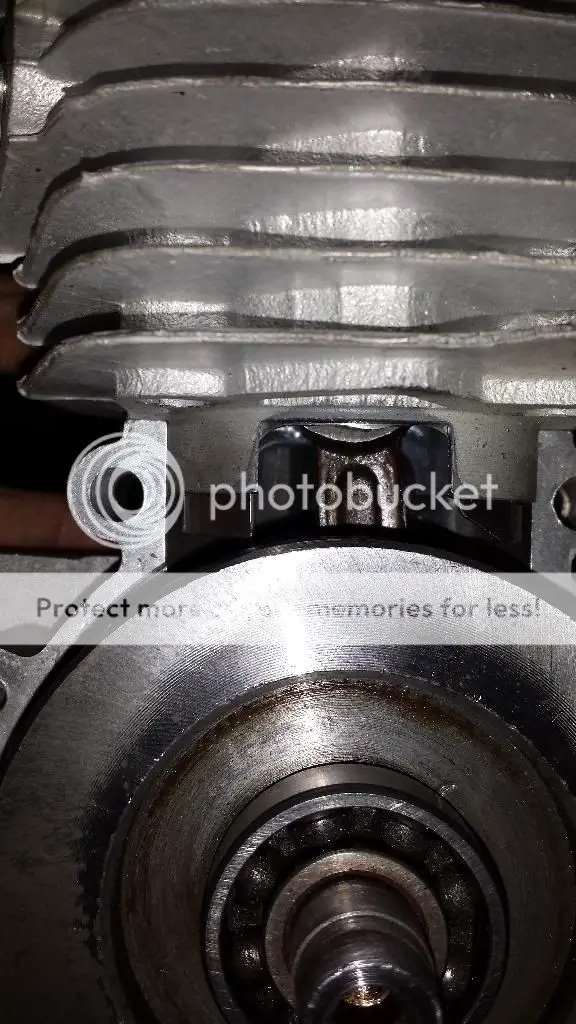

I like the idea of the teflon bushings on the lower end as they would effectly keep the bearings from creeping out of their bores under extreme conditions without any way to harm the engine as well as like you mentioned it could help prevent the crank from bending from the stress of high power and rpm, these could also be made oversized to help occupy space and add some case compression, they may need to be chamfered a little tho if oversized to allow some of the fuel/oil mix to reach the bearings. oversizing them may also help dampen out any high rpm harmonics as well, depending on size, shape, and how much room there is in there...

For a carb, I went with the Tillotson HS254B since it has the same 21mm bore with a 19mm venturi. I also got some aluminum bar stock coming in so I can make a manifold adapter and possibly design a reed box, I may need some more bar stock for the reed box depending on the design I come up with and what reed cage will work best. I'm thinking the GY6 scooter reeds will work with the Tilly carb I ordered, then mill the intake side of the cylinder down to mount at the intake port similar to the Arrow setup, then buy another set of cases or bottom end with a 40mm crank to cut an opening on for a true case inducted setup. With the Tilly or Walbro floatless type carbs, we're not limited to runnnig them completely side draft so it will be possible to mount it at a 45 degree down draft eliminating any bends in the intake tract which would offer a more compact high performance induction system for bikes like mine with limited frame space.

I like the idea of the teflon bushings on the lower end as they would effectly keep the bearings from creeping out of their bores under extreme conditions without any way to harm the engine as well as like you mentioned it could help prevent the crank from bending from the stress of high power and rpm, these could also be made oversized to help occupy space and add some case compression, they may need to be chamfered a little tho if oversized to allow some of the fuel/oil mix to reach the bearings. oversizing them may also help dampen out any high rpm harmonics as well, depending on size, shape, and how much room there is in there...