Sleeving the holes will help a lot , but I am not going to say it will be okay that's your call. I have a Briggs powered bike and with everything on it it ends up being a very heavy bike.

Electra Super Deluxe w/briggs flathead.

- Thread starter Mr.GhettoRig

- Start date

i think you need to gusset the frame where you drilled the huge holes in it with 1/8 inch steel plate or L channel to add strength before you even try to weld it and avoid pot holes like the plague

Frames are cut and stretched / rewelded all the time but they NEVER leave the holes.You could think about cutting out the holed part and having a plug replacement welded in its place. If you have a local school shop willing to play for free; otherwise.... ( insert funeral music here ) Im thinking your hosed. Search and research BEFORE picking up power tools

so maybe, cut the chunk of piping off that has the holes. Then sleeve and reweld it so it will be back to "normal" and then just weld a plate in there for the engine? how well does a welded on plate hold on? though it's probably better for the engine to come loose than the frame to snap.

And yeah I defiantly need to get in the habit of researching before hand. Otherwise I'm gonna find myself short on materials, cash, and/or limbs.

I'll fix it, hopefully soon.

And yeah I defiantly need to get in the habit of researching before hand. Otherwise I'm gonna find myself short on materials, cash, and/or limbs.

I'll fix it, hopefully soon.

Great start and good motor selection. I've built several Briggs powered bikes starting about 25 years ago and really like the power and sound of the 5hp flathead. You don't really need a massive engine mount, just some flat 1/8'' steel plates welded to the frame will do it. I've never had a frame crack. In fact the motor's triangulation actually strengthens the frame. I hope to see you finish this project.

OH hey there Msrfan, It was actually the admiration of those bikes that got me motivated to start this project in the first place. You did a really great job. I really like the briggs flathead as well, it's defiantly my favorite engine. Are you using the whizzer sheave on your bikes? how well do the spokes hold up to the abuse? or do you have a special wheel that can handle it?

I'm gonna call up the guy that helps me out with welding today and see if he can help me fix my mistake and also get to work on making that fake tank useable.

I'm gonna call up the guy that helps me out with welding today and see if he can help me fix my mistake and also get to work on making that fake tank useable.

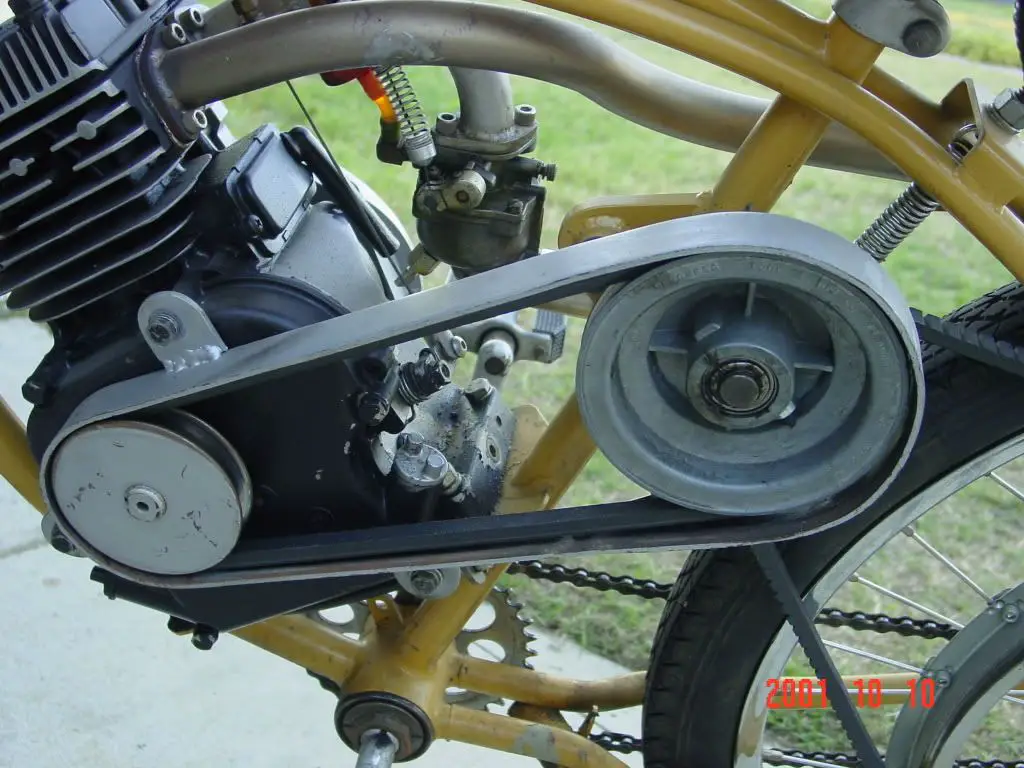

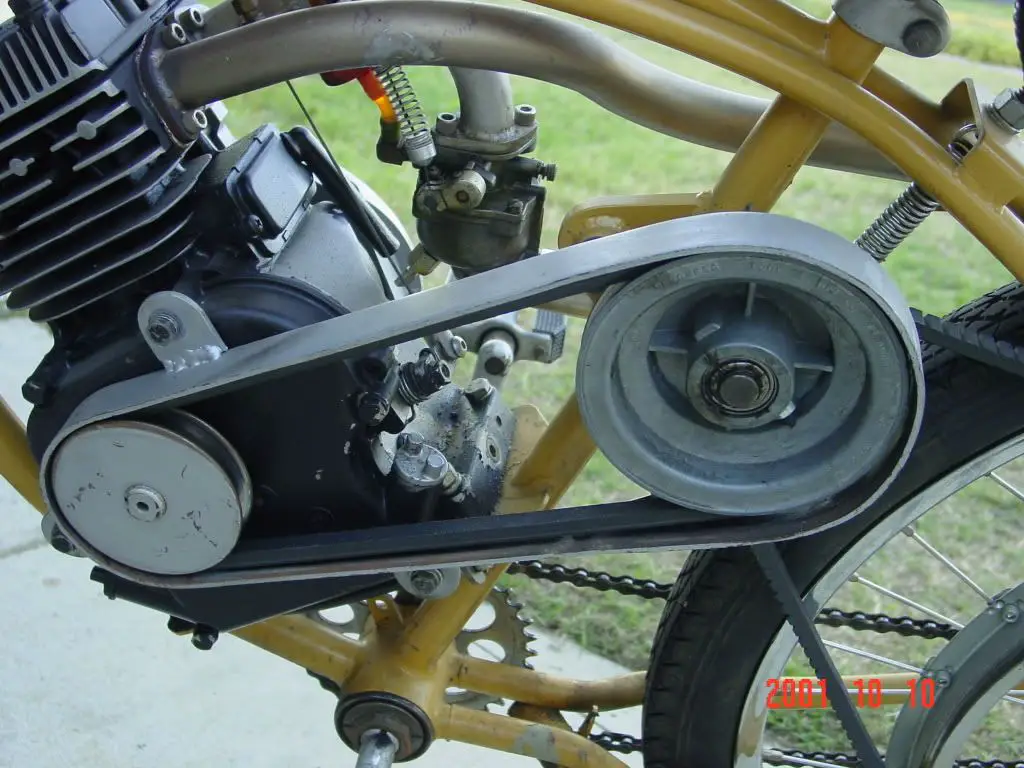

Thanks. The rear pulley strengthens the wheel by tying the spokes together. I always use a good steel rim like a Schwinn S-2, or a heavy single wall. Worksman is another super strong wheel but very heavy. .105 minimum spoke size or larger is the way to go with a cross four or cross three pattern. Never had a wheel problem, even on my race bike.

Good luck with your fab work. I'll be watching this build closely as I always get inspiration for future projects.

Good luck with your fab work. I'll be watching this build closely as I always get inspiration for future projects.

I was looking at worksmans the other day, they're pricey but seem like the way to go. First concern is getting my frame repaired and motor mounted. Then I'll get at least the rear wheel to start and that whizzer sheave so I can get my frame modified to fit everything. I wanna try and get all or most of the welding related stuff done in the next couple weeks during break. Because juggling work, school, and projects makes it harder to get things done.

Ordered a steel 12 gauge spoke coaster brake rear wheel. I didn't end up going with the worksman because I found a decent heavy duty one from link I found on this site. I plan on going with disc breaks on the front to go with the monark springer fork.

How well do disc breaks work for you guys? I've never had a bicycle with disc breaks so I don't have much experience with them, but from what I've read they seem to be the best way to go.

Also I know I'm getting ahead of myself but I drew up a finished sketch and spent an hour or two creating a fully changeable paint scheme and finished product picture. this is just the theme I threw together for now but i'll probably change as the project progresses.

How well do disc breaks work for you guys? I've never had a bicycle with disc breaks so I don't have much experience with them, but from what I've read they seem to be the best way to go.

Also I know I'm getting ahead of myself but I drew up a finished sketch and spent an hour or two creating a fully changeable paint scheme and finished product picture. this is just the theme I threw together for now but i'll probably change as the project progresses.

Alrighty, it's been awhile since I've updated this, and the game plan my have changed a time or two.

First off, Got my engine put together with a tec h50 carb and one of a kind trophy velocity stack. haha all she needs is an air filter and a compression release mechanism for easy pedal starting.

the rest of the bike has undergone a few changes as well. Vintage Brooks seat, Tomos Moped forks, chopped rear fender, got my chain cover cut to fit but not mounted yet (waiting till after I fix my frame holes), and a real whizzer sheave instead of the 20" bicycle rim.

First off, Got my engine put together with a tec h50 carb and one of a kind trophy velocity stack. haha all she needs is an air filter and a compression release mechanism for easy pedal starting.

the rest of the bike has undergone a few changes as well. Vintage Brooks seat, Tomos Moped forks, chopped rear fender, got my chain cover cut to fit but not mounted yet (waiting till after I fix my frame holes), and a real whizzer sheave instead of the 20" bicycle rim.

Last night I got a few hours in the garage and decided to make my headlight mount. Currently the bulb is dead and the casing has holes drilled in the side, but I'll have all that fixed up before too long.

hopefully in the next week or so I can get the down tube cut out and weld in a new "swoop" one so the engine can sit straight up and down. The only parts I have yet to gather are two moped drum hubs, and a cap/bung kit for my tank. I know I'm slow but hopefully soon It'll be out on the road, I can't wait.

hopefully in the next week or so I can get the down tube cut out and weld in a new "swoop" one so the engine can sit straight up and down. The only parts I have yet to gather are two moped drum hubs, and a cap/bung kit for my tank. I know I'm slow but hopefully soon It'll be out on the road, I can't wait.

got my chopped fender mounted... took an hour or two longer than it really should have but I got it done finally.

Basically it's mounted with a bent machine screw, with two nuts securing it to the fork plate, and an extremely ugly bracket that holds the screw to the headlight mount as well. It's ugly but it seems to hold up and the wheel doesn't hit the fender this time. I'll clean it all up later on.

Gettin'er done little bits at a time, hopefully I'll be able to get the frame cut up and fixed by this weekend.

And also I ordered two drum hubs. rear is a Motobecane, and the front is a Puch repro, so brakes shouldn't be as much of a concern once they get here.

Basically it's mounted with a bent machine screw, with two nuts securing it to the fork plate, and an extremely ugly bracket that holds the screw to the headlight mount as well. It's ugly but it seems to hold up and the wheel doesn't hit the fender this time. I'll clean it all up later on.

Gettin'er done little bits at a time, hopefully I'll be able to get the frame cut up and fixed by this weekend.

And also I ordered two drum hubs. rear is a Motobecane, and the front is a Puch repro, so brakes shouldn't be as much of a concern once they get here.

keep on it, a little at a time 1 day a week and before you know it.. another way is put it in the front room... but that can have its drawbacks, guys will dig it, wife/girlfriends just dont get it. ya i got a indian stayin in the office room, the feather kind, not the dot kind.

Brakes came in today, the rear is a lot bigger than I was expecting and the front one doesn't seem to have a place to attach a mounting bracket, unless you're supposed to attach your own in place of one of those red caps? I'm a newb when it comes to moped parts. also they didn't come with wheel nuts and the rear didn't come with a sprocket, so I'll have to order those separately and hope they get here by the time I have my new front wheel. but overall I'm mostly satisfied, once it's all set up I should have no problem stopping. I also have the kill switch all wired up, but other than that I still haven't made much progress. tomorrow is payday so I'll have a few more parts on the way soon, and if I can ever find a weekend off of work I'll be able to finally fix my frame. anyway, here's a fuzzy pic of the brakes.

Okay Ghetto, the red caps are to be removed to inspect brake shoe wear and then replaced to keep dirt out of the drum. Moped forks usually come with a rectangle piece of metal welded to the lower leg near the axle that slips into the groove on your front drum brake plate and doubles as a fender strut mount. I see yours has the groove, so if your forks don't fit into it, you have to make a piece that reaches the groove and weld it onto your forks. I just took a look at the photo of your forks and see the nub that fits the brake drum that originally came with the Tomos forks. If the nub doesn't fit your brake, you will have to enhance it until it does. It's very important that the slip fit connection from the forks to the brake hub is solid. A lot of us have been over the bars due to neglecting this area. The spokes should swing outward from the center and fit the hub without changing lengths. Occasionally I have spoked a large flange hub and the threaded ends protruded a some past the nipple and I had to grind a little off. Moped axles are normally either 11mm X 1mm diameter and pitch, or 12mm X 1mm. Kind of a fine pitch but you may find them at industrial hardware stores or obviously a moped shop if there's one available. Keep going and you'll have'r done in no time.