This year, a few classmates and I are in the power mechanics class. In this class, we are fabricating a car for the MTEEA supermileage challange this year, at brainerd international raceway. I figured that I would start a build thread here to get some opinions, and possibly some help with any problems that may rear up.

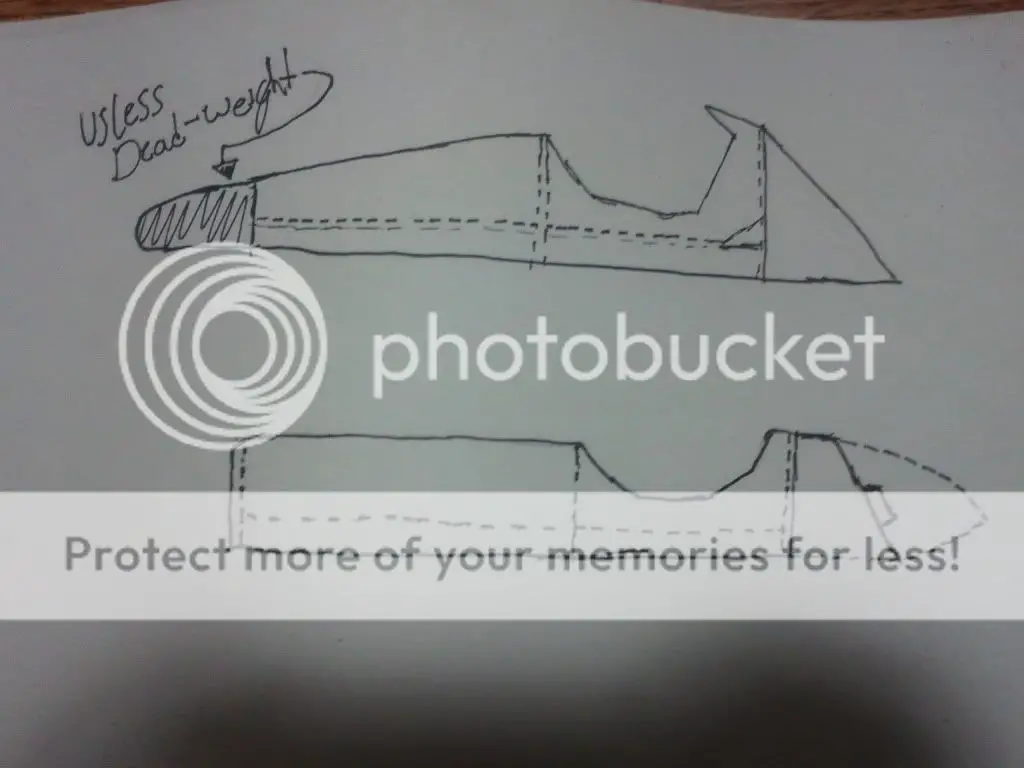

Here's our car

And here is warren, known as choppercrazy on here, working on the air intake for the carburetor.

We're going to work on running a 3 speed sturmy archer hub with an 80 tooth drive sprocket over the cog on the hub, so we would be able to use the three different gears in the race to try to save a bit more gas. Also in our agenda, we are going to get rid of the dorky stock pancake muffler and put a lower resistance one on it, and do a cold air intake from outside of the car. We are using a 2.4 hp briggs engine, with a 10 tooth #35 chain clutch. I'll try to post pictures of our progress, and updates on how we do at B.I.R this year.

Cheers, ccd.

Here's our car

And here is warren, known as choppercrazy on here, working on the air intake for the carburetor.

We're going to work on running a 3 speed sturmy archer hub with an 80 tooth drive sprocket over the cog on the hub, so we would be able to use the three different gears in the race to try to save a bit more gas. Also in our agenda, we are going to get rid of the dorky stock pancake muffler and put a lower resistance one on it, and do a cold air intake from outside of the car. We are using a 2.4 hp briggs engine, with a 10 tooth #35 chain clutch. I'll try to post pictures of our progress, and updates on how we do at B.I.R this year.

Cheers, ccd.