Well everyone,

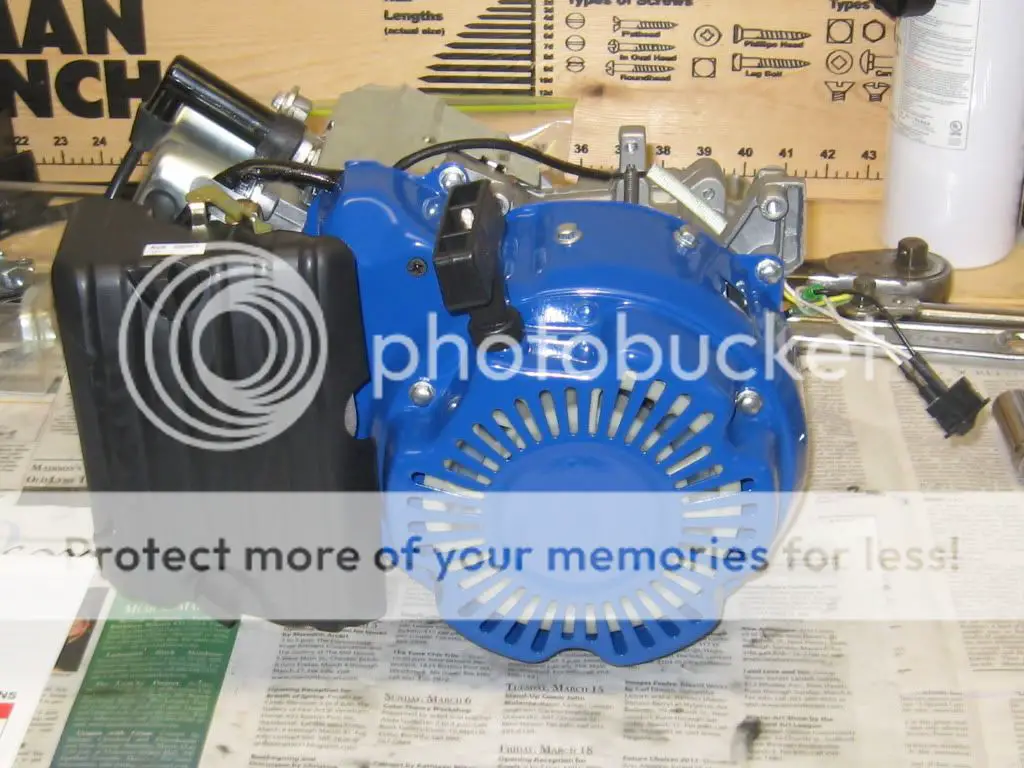

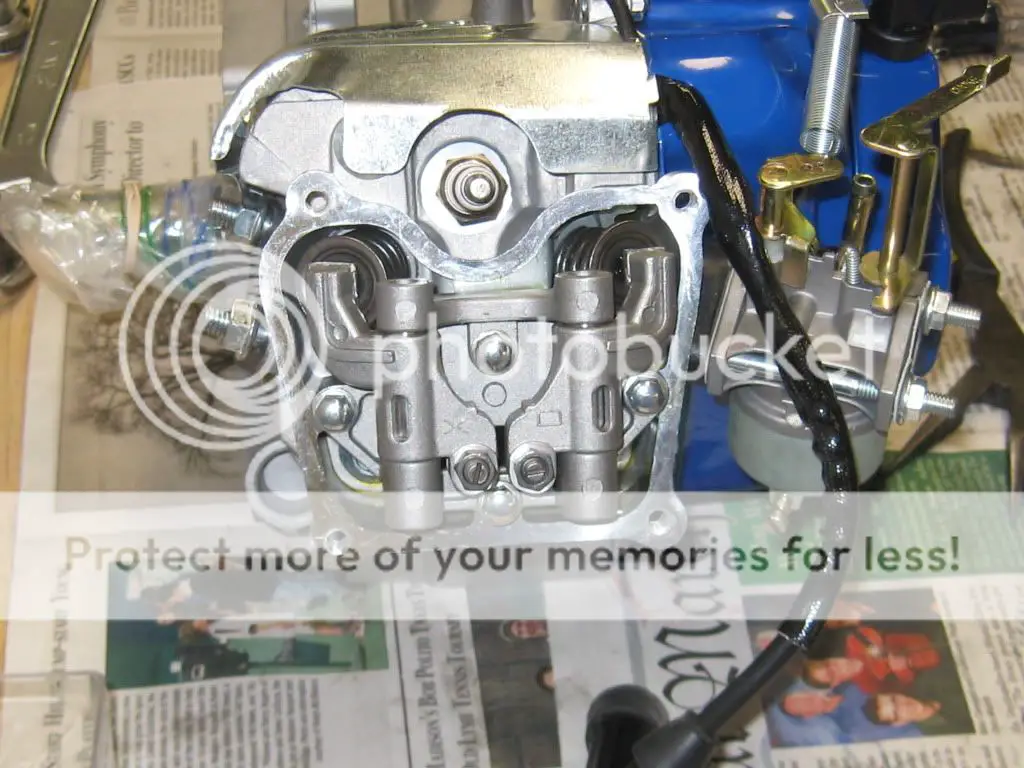

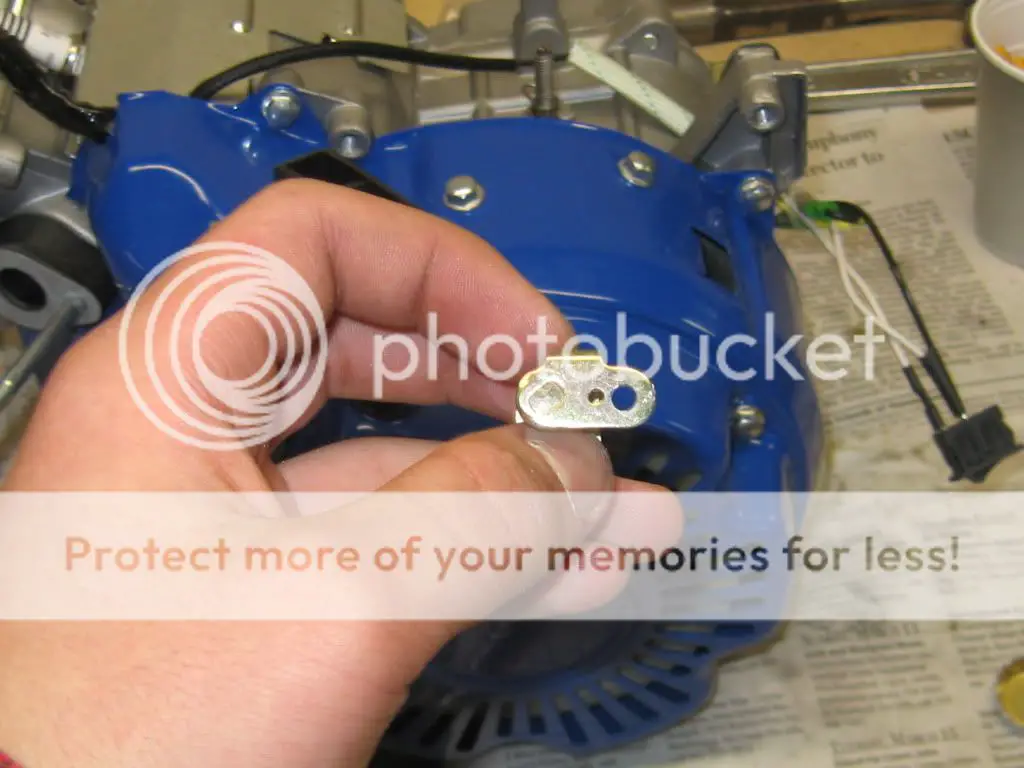

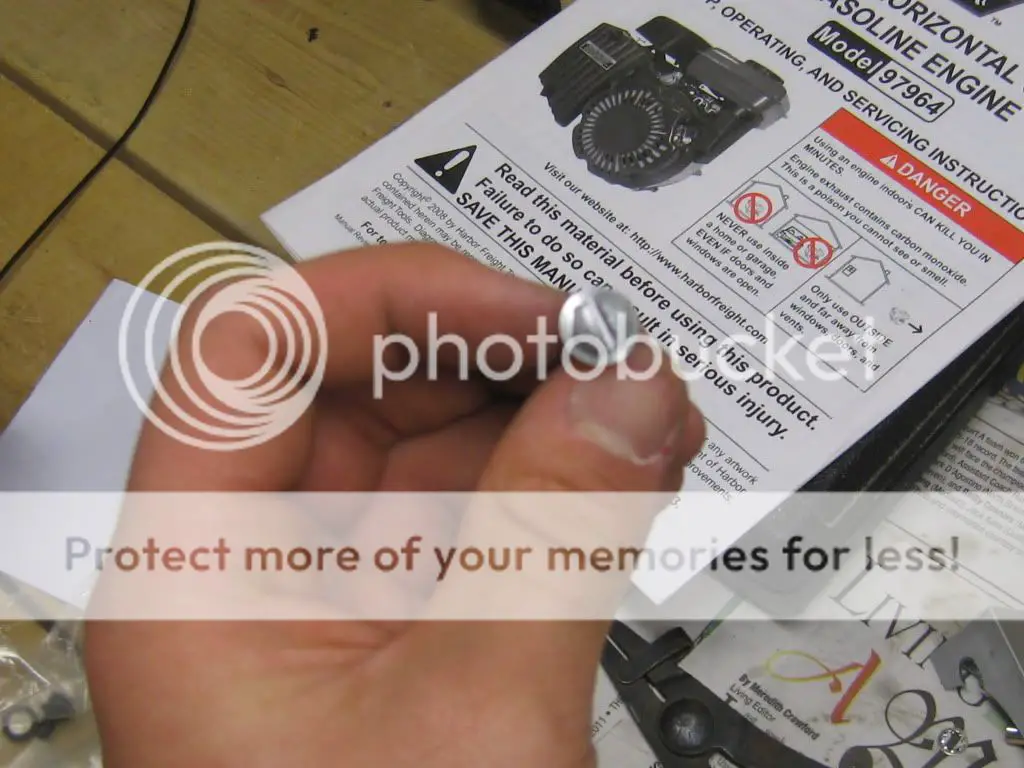

I'm starting my build for my Schwinn Riverside. I bought the HF 79cc Greyhound today at Harbor Freight with a 20% off coupon. It totaled $101 with CT tax. Not bad for a darn sturdy engine. I really like the look and design, it feels like you could throw it at people, kill them, and still have a working engine . Here are some pictures of what I did today. I removed the tank, muffler, and the external governing system. Please tell me someone if I removed too much of the governing system, I just left the shaft that comes out of the engine. I also have a side by side comparison of the cheap chinese spark plug, and a US made autolite double platinum which I gapped at .028" I hope to run this thing some time this week. I'm starting with normal castrol for break in, then switching to synthetic after. Also, I've heard that people have removed the low oil sensor, what is the advantage to that and how do you do it without making an engine that will not run at all ? Peace

. Here are some pictures of what I did today. I removed the tank, muffler, and the external governing system. Please tell me someone if I removed too much of the governing system, I just left the shaft that comes out of the engine. I also have a side by side comparison of the cheap chinese spark plug, and a US made autolite double platinum which I gapped at .028" I hope to run this thing some time this week. I'm starting with normal castrol for break in, then switching to synthetic after. Also, I've heard that people have removed the low oil sensor, what is the advantage to that and how do you do it without making an engine that will not run at all ? Peace

-LS

I'm starting my build for my Schwinn Riverside. I bought the HF 79cc Greyhound today at Harbor Freight with a 20% off coupon. It totaled $101 with CT tax. Not bad for a darn sturdy engine. I really like the look and design, it feels like you could throw it at people, kill them, and still have a working engine

. Here are some pictures of what I did today. I removed the tank, muffler, and the external governing system. Please tell me someone if I removed too much of the governing system, I just left the shaft that comes out of the engine. I also have a side by side comparison of the cheap chinese spark plug, and a US made autolite double platinum which I gapped at .028" I hope to run this thing some time this week. I'm starting with normal castrol for break in, then switching to synthetic after. Also, I've heard that people have removed the low oil sensor, what is the advantage to that and how do you do it without making an engine that will not run at all ? Peace

. Here are some pictures of what I did today. I removed the tank, muffler, and the external governing system. Please tell me someone if I removed too much of the governing system, I just left the shaft that comes out of the engine. I also have a side by side comparison of the cheap chinese spark plug, and a US made autolite double platinum which I gapped at .028" I hope to run this thing some time this week. I'm starting with normal castrol for break in, then switching to synthetic after. Also, I've heard that people have removed the low oil sensor, what is the advantage to that and how do you do it without making an engine that will not run at all ? Peace-LS

Thanks LS!!

Thanks LS!!