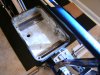

A little more progress. Fabed the engine mounting system I guess you would call it. The fuel tank is actually the mount. This engine had the cast aluminum tank. It was originally hung by a mount on the cylinders in the washer, so there are no mounting bosses on the tank, and the tank is painfully thin as it job was just to hold fuel. The mounts actually go through the tank floor. Angle iron plates spread the load over a large area, bolts are threaded into a center piece of angle on the bottom of the tank that fits perfectly into the two angle engine mounts(its on backwards in the pic). There is an adjustment bolt at the back of the tank to adjust belt tension by sliding the engine. All of this is locked into position by plates tightened against the angle engine mounts(shorter bolts of course!). The tank pieces will be sealed/bonded to the tank with JB weld. Its very substantial if the tank takes it, don't think it an issue with the low HP produced. Also got the exhaust started will, be 3/4 copper paralleling the front down tube to get the exhaust down on the road near the bottom bracket. Don't want it any where near me at a 16:1 mix ratio! Was a real trick to get it to clear the frame.