I know most experienced builders say to avoid trying to dampen vibration and mount the motor solidly. But I think I have a twist to previously mentioned methods that may actually work, and not result in broken mounting studs. Bear in mind that;

- studs have been replaced with US made 6mm all thread

- the pads are designed to absorb vibration transfer from skateboard trucks to the rider

A typical motorcycle motor mount uses rubber or urethane between two metal plates. This method seems very similar to my non-engineering mind. Why will it work or not work? OK, let me have it!

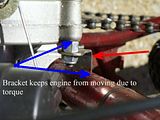

See pic. Thanks!

- studs have been replaced with US made 6mm all thread

- the pads are designed to absorb vibration transfer from skateboard trucks to the rider

A typical motorcycle motor mount uses rubber or urethane between two metal plates. This method seems very similar to my non-engineering mind. Why will it work or not work? OK, let me have it!

See pic. Thanks!

Attachments

-

85.9 KB Views: 692