So, while doing my electrical work on the flying horse, I noticed that only 2 strands of the blue wire were soldered to the tab...i had a 12"section of 12guage, 24 strand wire...wow what a difference...seems that more wire equals more power...I'm sold...i will be doing that to every mag coil I get...anyone else do this? I'm interested to hear your input...thanks...wickedest

Heavy guage wire

- Thread starter Wickedest1

- Start date

Seriously, I just did the same to my buddies bike and he went from a 32mph top speed to 38mph...found a police speed trap thingy and consistently got 38...my bike personally went from 23mph top speed to 29mph...consistently...please try this...so long as you can solder that is...

12 gauge? That's huge for these little ignition systems. 16 gauge is still overkill, but there is no harm in going bigger.

I commonly use 16 and 18 gauge when fabricating a motorcycle harness.

If LED lights are used I'll go as small as 22 gauge for hiding the wires and fishing them through the frame, ect.

Thanks for the tip, I may go bigger with my wires. I also question the integrity of the Chinese wire and especially the factory soldered connections.

I commonly use 16 and 18 gauge when fabricating a motorcycle harness.

If LED lights are used I'll go as small as 22 gauge for hiding the wires and fishing them through the frame, ect.

Thanks for the tip, I may go bigger with my wires. I also question the integrity of the Chinese wire and especially the factory soldered connections.

G'day Guys,

Integrity of your electrical connections is essential. The nature of electrical energy is that current flows at the outer surface of the conductor. One term for it in trade is "skin effect". The larger the cross sectional area of a conductor, the higher the current capacity of that wire/cable.

Another tip: When you use crimp terminals, DO NOT solder them. They are actually designed to be crimped and function better when crimped. If you solder them, you will find that (due to the amount of heat you need to apply to get the solder to flow on the crimp terminal) solder wicks it's way up your wire and makes the wire itself rigid. If you use the appropriate position on your crimping tool, the joint will hold and last just fine. Just look to ensure that when you strip back the insulation, you don't strip it too far or it will "bird cage". This will weaken the mechanical integrity of the electrical connection and reduce the current carrying capacity of your wire.

Brett.

Integrity of your electrical connections is essential. The nature of electrical energy is that current flows at the outer surface of the conductor. One term for it in trade is "skin effect". The larger the cross sectional area of a conductor, the higher the current capacity of that wire/cable.

Another tip: When you use crimp terminals, DO NOT solder them. They are actually designed to be crimped and function better when crimped. If you solder them, you will find that (due to the amount of heat you need to apply to get the solder to flow on the crimp terminal) solder wicks it's way up your wire and makes the wire itself rigid. If you use the appropriate position on your crimping tool, the joint will hold and last just fine. Just look to ensure that when you strip back the insulation, you don't strip it too far or it will "bird cage". This will weaken the mechanical integrity of the electrical connection and reduce the current carrying capacity of your wire.

Brett.

It also helps to sand off the varnish from the magneto body so that it will have a better 'ground' to the engine case.

Did it to a 3rd magneto today for a guy that weighs 285 and is 6'6"tall...he runs one of those onyx 29ers, and instantly upon first fire and ride the guy was sold...me too...36tooth rear sprocket on a29" wheel...whoo that dang bike hauls...may look at that for aswap bike......and I apologize its not 12guage its 14...and I've had to drill out the white plastic nut that the wires run through...

I don't think its the bigger gauge, but the better wire and connections then what the kits come with.

I always re-do the wiring on every kit, and you do notice a difference sometimes just by adding better terminals then what is provided with the kits.

I always re-do the wiring on every kit, and you do notice a difference sometimes just by adding better terminals then what is provided with the kits.

When I recieve my flying horse engine in a week I will try doing this. So I just change out all of the wires? Should I use stranded wire or solid? Nudge a noob in the right direction

The black is ground, white accessory, blue is your power to the cdi...i got rid of the white wire completely...just desoldered the "wire".from the solder tab...i used stranded wire solely for the flexibility...you may have to drill out the cap that screws into the engine block so the wires can fit...and I've only changed the magneto wires...I'm afraid to open the little black box (cdi)...and get an automotive spark plug wire...When I recieve my flying horse engine in a week I will try doing this. So I just change out all of the wires? Should I use stranded wire or solid? Nudge a noob in the right direction

Good luck...

Last edited:

Hey if done right you won't get wicking of the solder up the wire. Also a soldered connection is going to conduct far batter than a crimped one. If crimped connection are exposed to the weather they will fail faster than a soldered one. I base what I say by experience and knowledge.G'day Guys,

Integrity of your electrical connections is essential. The nature of electrical energy is that current flows at the outer surface of the conductor. One term for it in trade is "skin effect". The larger the cross sectional area of a conductor, the higher the current capacity of that wire/cable.

Another tip: When you use crimp terminals, DO NOT solder them. They are actually designed to be crimped and function better when crimped. If you solder them, you will find that (due to the amount of heat you need to apply to get the solder to flow on the crimp terminal) solder wicks it's way up your wire and makes the wire itself rigid. If you use the appropriate position on your crimping tool, the joint will hold and last just fine. Just look to ensure that when you strip back the insulation, you don't strip it too far or it will "bird cage". This will weaken the mechanical integrity of the electrical connection and reduce the current carrying capacity of your wire.

Brett.

Crimped connectors are used because they are cheap and fast to install. They make it easier to do replacements later also. Soldered connection last longer and can flow more amperage through the connection. They do not heat up as much as a crimped connection does and they are stronger.

Attachments

-

42 KB Views: 264

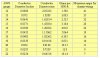

Just used google to find a chart of what I have in some of the books I own.Draco, I haven't a clue where you come up with all this great info but thanks for the table...

Here is a YouTube video that should help those that are not that well versed in soldering.

How to Do It: Basic Soldering

How to Do It: Basic Soldering

Is there any problem with using a bigger gauge wire? Im thinking say 16 gauge to 12 gauge wire. Will I lose any current from having a larger wire like that? Or will it give me the benefit of extra current flow?

A larger Wire Gauge will only let more current flow through it, but will not give you more current than there is current available from the source. In other words if the source only has 1 amp of current going to a larger gauge will not make it become 2 amps of current. But if you use to small of a wire gauge you will overheat the wire and cause a short or an open to happen. Hope that helps you out. Bottom line at some point you will just be wasting money on a larger gauge wire that isn't needed.Is there any problem with using a bigger gauge wire? Im thinking say 16 gauge to 12 gauge wire. Will I lose any current from having a larger wire like that? Or will it give me the benefit of extra current flow?

okay good to know, thanks for clarifying. So the results of a stronger running engine from having the stock wires replaced, posted about at the begining of this thread by the OP are true. So im thinking I should replace the wiring on my kit but once i reach a certain size of wire, it becomes unnecessary? Is that the basic idea?A larger Wire Gauge will only let more current flow through it, but will not give you more current than there is current available from the source. In other words if the source only has 1 amp of current going to a larger gauge will not make it become 2 amps of current. But if you use to small of a wire gauge you will overheat the wire and cause a short or an open to happen. Hope that helps you out. Bottom line at some point you will just be wasting money on a larger gauge wire that isn't needed.

Yep, that is it. Lets say what you are able to supply is 15 to 16amps you could use 18 gauge wire based on the chart I posted, but for safety I would use 16 gauge wire which can handle 22 amps based on the chart. Where 14 or 12 gauge wire would just be overkill and a waste of money.okay good to know, thanks for clarifying. So the results of a stronger running engine from having the stock wires replaced, posted about at the begining of this thread by the OP are true. So im thinking I should replace the wiring on my kit but once i reach a certain size of wire, it becomes unnecessary? Is that the basic idea?

Exactly.okay good to know, thanks for clarifying. So the results of a stronger running engine from having the stock wires replaced, posted about at the begining of this thread by the OP are true. So im thinking I should replace the wiring on my kit but once i reach a certain size of wire, it becomes unnecessary? Is that the basic idea?

Bigger is not necessarily better when big enough passes more than enough current for optimum performance. If you want to use 1/0 gauge Monster Audio power cable you can, but any benefit will only be for looks. 16 or 14 gauge wire is more than big enough.