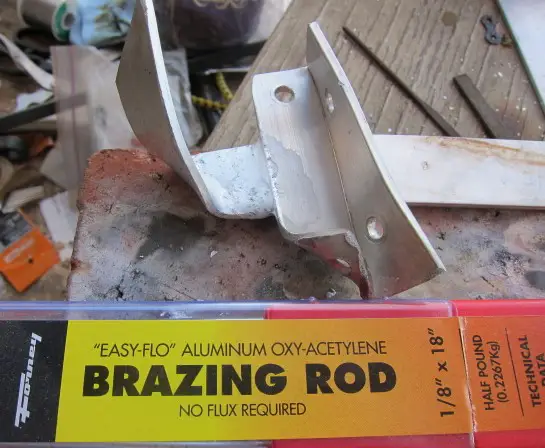

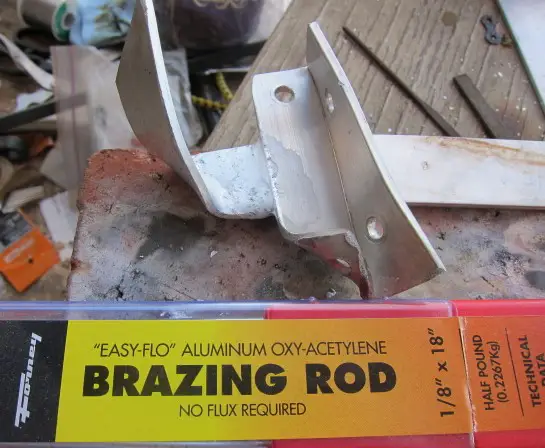

This is so cool. I saw this stuff on the internet but didn't buy because it was really expensive. Then I saw some at the hardware store and thought why not? Don't need oxy-acetylene, just propane and a stainless steel brush. You just heat the part, scratch the rod until it melts and then brush the melt to "tin" the area.

Then put the prepped parts together and scratch and flow more rod into the joint;

You can see how some of the stock has dissolved into the melt. That was encouraging, what I was looking for. But is it strong, will it hold? One way to find out eh, give it the "hammer test"

So I put the "cross" on the pavement and beat the crap out of it;

Not even one little crack. This is so cool! Just think of all the cool aluminum stuff you can do w/o a welder!

That was my first joint. Now I'm confident enough to build up the battery box for the Motoped

Then put the prepped parts together and scratch and flow more rod into the joint;

You can see how some of the stock has dissolved into the melt. That was encouraging, what I was looking for. But is it strong, will it hold? One way to find out eh, give it the "hammer test"

So I put the "cross" on the pavement and beat the crap out of it;

Not even one little crack. This is so cool! Just think of all the cool aluminum stuff you can do w/o a welder!

That was my first joint. Now I'm confident enough to build up the battery box for the Motoped