Has anyone heard of the scale miniature motorcycle engines, and or ordered the plans for one.

I found this company online that sells the plans to build a vintage or scale motorcycle engine.

Jerry E. Howell Model Project Plans & Kits

Outpost Enterprises, LTD - 695 Godfrey Road - Hollansburg - Ohio 45332 - USA

(World Wide Supplier of Quality Model Project Plans & Kits Since 1992)

"Howell V-Twin" 4-Cycle Gas Engine: JEH - "Howell V-Twin" Engine page

Here's some info about this V-Twin Engine Build Kit 32cc.

This is a V-Twin engine that is machined entirely from bar stock. It has no prototype as it is entirely my own design. Being a single crank pin 90 degree engine, it is extremely smooth and vibration free. V type engines other than 90 degree can not be balanced except with special balancer shafts, etc. that you wouldn't want! Witness the vibrating 45 degree motorcycle engines...... The engine is a long stroke, moderate speed design which provides plenty of torque. A robust cooling system allows the engine to run indefinitly with a load and never overheat.

Cylinders are of cast iron. Crankshaft is steel. Most of the rest of the engine is of aluminum alloy. Knife and fork aluminum alloy connecting rod ends operate on a single hardened crank pin. This configuration produces an interesting exhaust sound! An internal oil pump ensures that lots of oil gets to all the internal moving parts. The crankcase holds two ounces of oil.

The engine is equipped with ball bearings on all rotating shafts. A sheet metal shroud on each cylinder/head directs cooling air from a pair of belt driven fans. Dual 2-Jet Throttles have oiled foam air cleaners. The valve rocker arms have ball bearing rollers on the valve stem end and clevises with lock nuts on the push rods for valve clearance adjustment on the other end of the rocker arms. The valve train is designed so that there is no side thrust on the tappets or the rocker arms which causes undue wear on other engines.

The engine operates without any oil getting on the outside due to "O" ring seals at all joints and an efficient crankcase check valve ventilation system which maintains negative crankcase air pressure.

The ignition system is twin Hall sensor and twin TIM-6 electronic ignition modules and two model engine coils operating on 6 volts. Each cylinder is treated as a seperate engine and this precludes the need for a distributor. The spark advance/retard is easily adjusted during operation. Spark plugs are the low cost 10mm NGK CM-6.

This is NOT a beginners project, but anyone who is particular about his work, has built a few other successful internal combustion engines and has a 7 inch or larger lathe and a milling machine with a 6 inch rotary table should not have any problems building this engine.

Besides just being a nice engine to have and operate, this engine would be great fun on a bicycle or in a radio controlled boat, car, tank, etc.! This is a small "real world" industrial quality engine capable of doing "long hours" of hard work. My engine operates all day long at shows driving a generator and is stopped only long enough for refueling.

The plans include all engine features in the photos (except the mounting rails) including the throttles, cooling fans and air shrouds, plus an ignition system schematic diagram and timing gear cutting charts.

The quality CAD generated and laser printed plans set consists of 41 sheets of drawings and 3 sheets of construction notes.

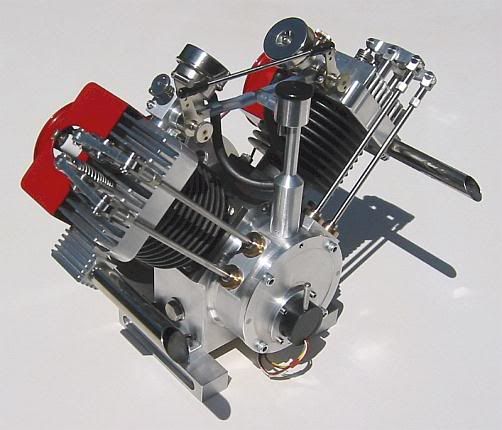

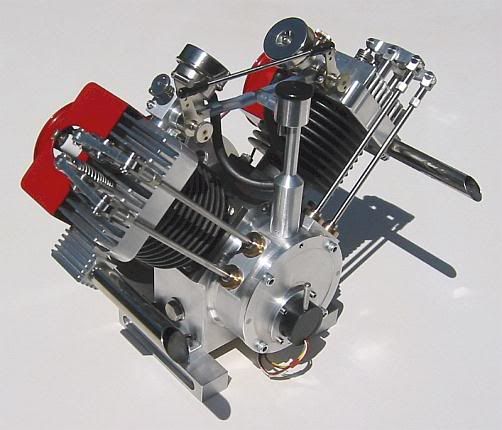

Here's few pic's to drool over.

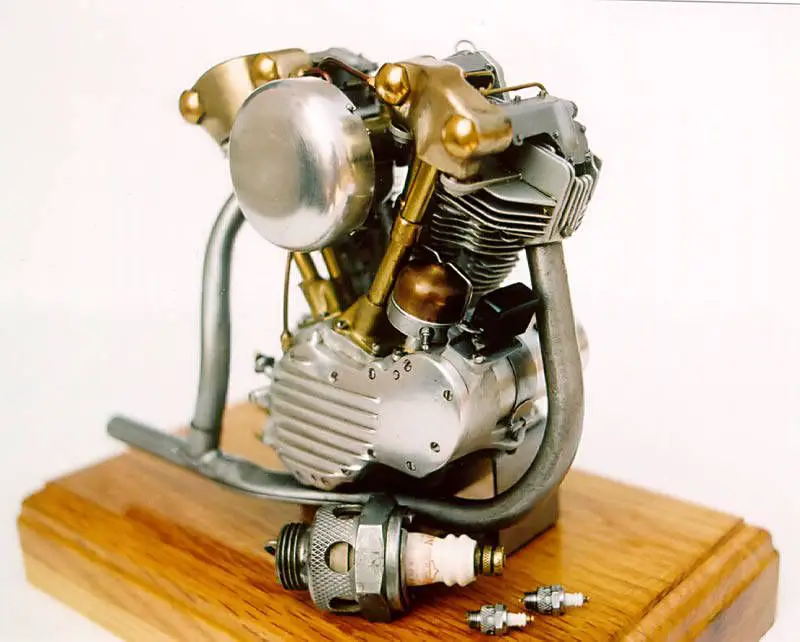

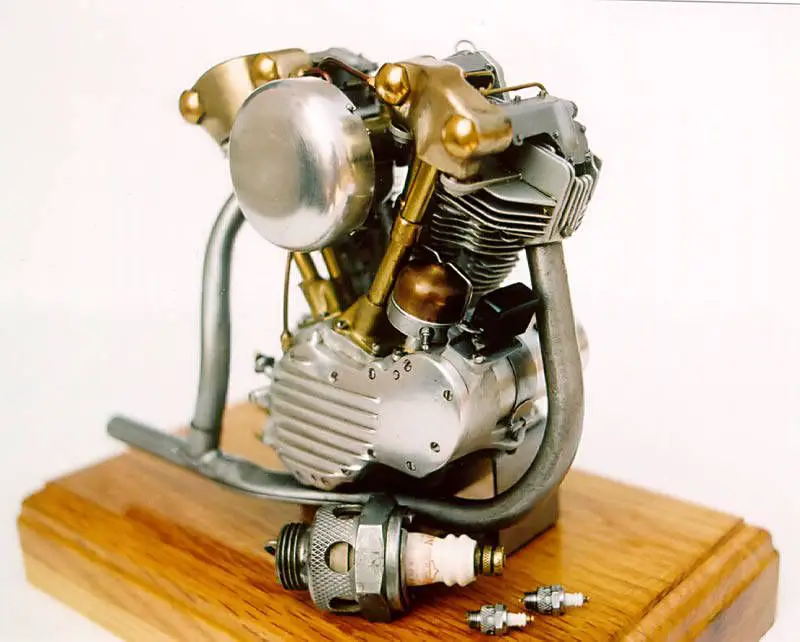

Here is forum members Cam & jdmpunks of Acme Motor Bikes 2-stroke mini v-twin engine below.

I wonder just how difficult it really would be to fabricate one of these CNC Milled engines, anyone here in the forum know anything about this manufacturing process? Jim ( Creative Engineering ), maybe?

I've only just begun my research on this type of engine manufacturing using the CNC Machining Process!

Just imagine how much information can be found with just our forum members searching the web, and or forum members who are experienced machinists that can further educate our forum members about building Scaled fully functional V-Twin engines.

This can't be to expensive to build as many others on Youtube have posted videos of their engines running.

Please do help share in this research / information about scaled engines, that you have found or know about!

Any forum members up for this that is building your own vintage style engine. Bairdco, I'm sure you already know of these engines and have been on it!

Peace Crazy Horse.

Peace Crazy Horse.

I found this company online that sells the plans to build a vintage or scale motorcycle engine.

Jerry E. Howell Model Project Plans & Kits

Outpost Enterprises, LTD - 695 Godfrey Road - Hollansburg - Ohio 45332 - USA

(World Wide Supplier of Quality Model Project Plans & Kits Since 1992)

"Howell V-Twin" 4-Cycle Gas Engine: JEH - "Howell V-Twin" Engine page

Here's some info about this V-Twin Engine Build Kit 32cc.

This is a V-Twin engine that is machined entirely from bar stock. It has no prototype as it is entirely my own design. Being a single crank pin 90 degree engine, it is extremely smooth and vibration free. V type engines other than 90 degree can not be balanced except with special balancer shafts, etc. that you wouldn't want! Witness the vibrating 45 degree motorcycle engines...... The engine is a long stroke, moderate speed design which provides plenty of torque. A robust cooling system allows the engine to run indefinitly with a load and never overheat.

Cylinders are of cast iron. Crankshaft is steel. Most of the rest of the engine is of aluminum alloy. Knife and fork aluminum alloy connecting rod ends operate on a single hardened crank pin. This configuration produces an interesting exhaust sound! An internal oil pump ensures that lots of oil gets to all the internal moving parts. The crankcase holds two ounces of oil.

The engine is equipped with ball bearings on all rotating shafts. A sheet metal shroud on each cylinder/head directs cooling air from a pair of belt driven fans. Dual 2-Jet Throttles have oiled foam air cleaners. The valve rocker arms have ball bearing rollers on the valve stem end and clevises with lock nuts on the push rods for valve clearance adjustment on the other end of the rocker arms. The valve train is designed so that there is no side thrust on the tappets or the rocker arms which causes undue wear on other engines.

The engine operates without any oil getting on the outside due to "O" ring seals at all joints and an efficient crankcase check valve ventilation system which maintains negative crankcase air pressure.

The ignition system is twin Hall sensor and twin TIM-6 electronic ignition modules and two model engine coils operating on 6 volts. Each cylinder is treated as a seperate engine and this precludes the need for a distributor. The spark advance/retard is easily adjusted during operation. Spark plugs are the low cost 10mm NGK CM-6.

This is NOT a beginners project, but anyone who is particular about his work, has built a few other successful internal combustion engines and has a 7 inch or larger lathe and a milling machine with a 6 inch rotary table should not have any problems building this engine.

Besides just being a nice engine to have and operate, this engine would be great fun on a bicycle or in a radio controlled boat, car, tank, etc.! This is a small "real world" industrial quality engine capable of doing "long hours" of hard work. My engine operates all day long at shows driving a generator and is stopped only long enough for refueling.

The plans include all engine features in the photos (except the mounting rails) including the throttles, cooling fans and air shrouds, plus an ignition system schematic diagram and timing gear cutting charts.

The quality CAD generated and laser printed plans set consists of 41 sheets of drawings and 3 sheets of construction notes.

Here's few pic's to drool over.

Here is forum members Cam & jdmpunks of Acme Motor Bikes 2-stroke mini v-twin engine below.

I wonder just how difficult it really would be to fabricate one of these CNC Milled engines, anyone here in the forum know anything about this manufacturing process? Jim ( Creative Engineering ), maybe?

I've only just begun my research on this type of engine manufacturing using the CNC Machining Process!

Just imagine how much information can be found with just our forum members searching the web, and or forum members who are experienced machinists that can further educate our forum members about building Scaled fully functional V-Twin engines.

This can't be to expensive to build as many others on Youtube have posted videos of their engines running.

Please do help share in this research / information about scaled engines, that you have found or know about!

Any forum members up for this that is building your own vintage style engine. Bairdco, I'm sure you already know of these engines and have been on it!

Peace Crazy Horse.

Peace Crazy Horse.