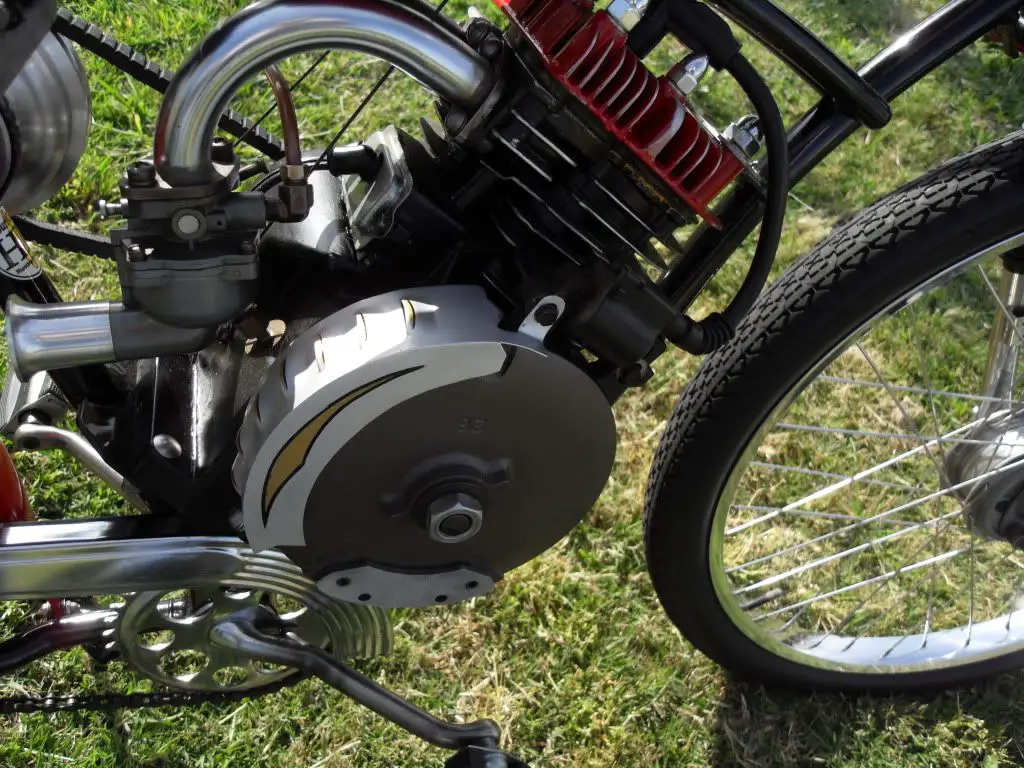

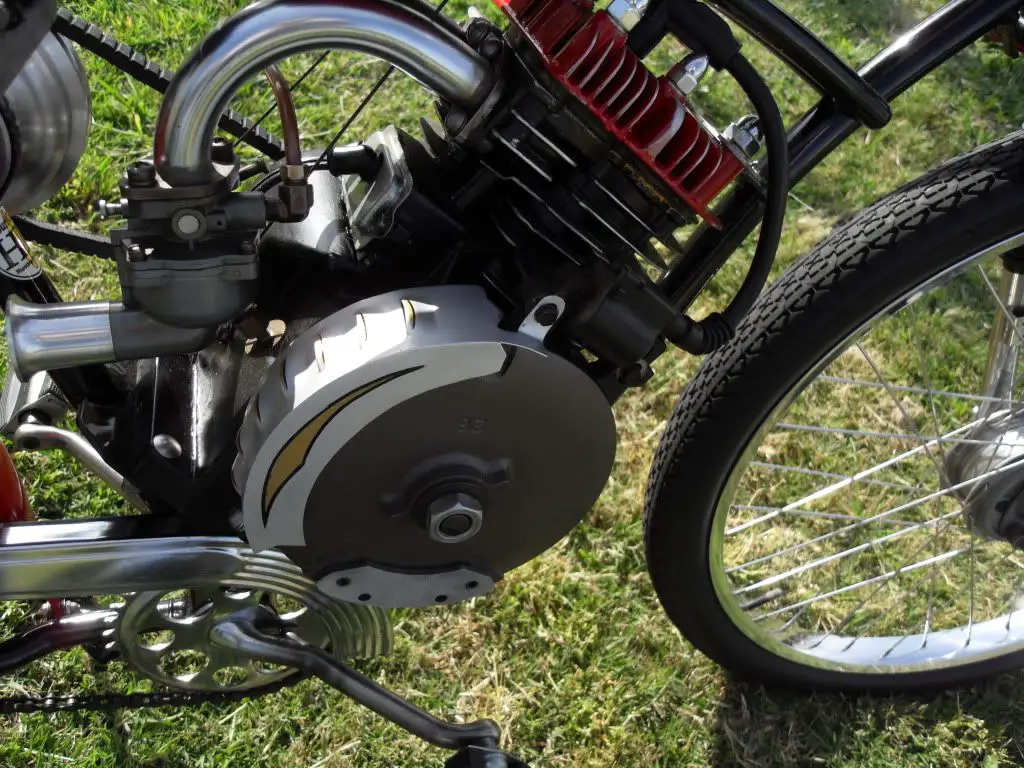

My friend, Dan, and I built this one about 4 years ago for him. This has all my latest ideas in one bike. Engine mounted Motobecane variator clutch, LED headlight and tailight with stoplight. Battery pack with charging system, weighted flywheel to make up for what we removed, all with his bobber look. A little port cleanup and it runs real strong. We had a heck of a time with the clutch. First we cut off the shaft holding the clutch and grafted it into a Briggs 5hp. The variator has three circuits. Starting shoes that fly out inside a drum when pedalling that starts turning the motor. We had to add 1/4" plates to those to make them heavy enough because moped motors turn at higher rpms. More shoes mounted onto the outside rim of that drum spring loaded to fly out in another drum that turns the wheels when the motor starts. We had to slot the springs so they would fly out easier. And finally steel balls on a ramp that squeezes the pulley halves together giving cvt ratios. Dan machined a new plastic part that holds twice the balls. It worked at last performs great. Batavus fuel tank, moped front drum break-forks-headlight-controls, and Honda ingnition coil. Now for the charging system. I had a brainstorm about using a Sturmey Archer Dynohub, so that's what we did. Dan machined a solid aluminum billet double pulley to accept the little alternator and 2 large bearings. Bulletproof. Riding on a hollow axle allows the wires to reach the frame nicely. Mounted on a double pivoting spring return bracket lets the whole mess swing forward and down when the front pulley closes, keeping consistent tension on both belts. Okay, the Dybohub puts out 6 volts when laced into a front wheel. Spinning it at motor speeds produces around 87 volts. After months of trying to figure out a rectifier-regulator I was walking down a row at the Golden West College swap meet and spotted a box full of charging modules for cell phones, etc. They're all 120 volts ac input, and the output varies but is always dc. So, with a little experimenting we put together a small battery pack, installed it into the headlight bucket and it's been keeping it charged perfectly. What a stroke of luck. There's an on-off switch hidden under the seat with the charging module. A small front sprocket to clear the engine and ease starting. It uses my standard internal compression release. Dan's had this bike up to 50mph on PCH, but it's just at home putting the neighborhood. The 5 on the forks stand for the fifth B&S bike build using my basic design. Got two more in the works. I will post as I go. Thanks for checking out my stuff. I love all the bikes I've seen on this forum.

What a sweet ride, I can just see myself cruising that one around. Awesome Thank You for sharing.

What a sweet ride, I can just see myself cruising that one around. Awesome Thank You for sharing.