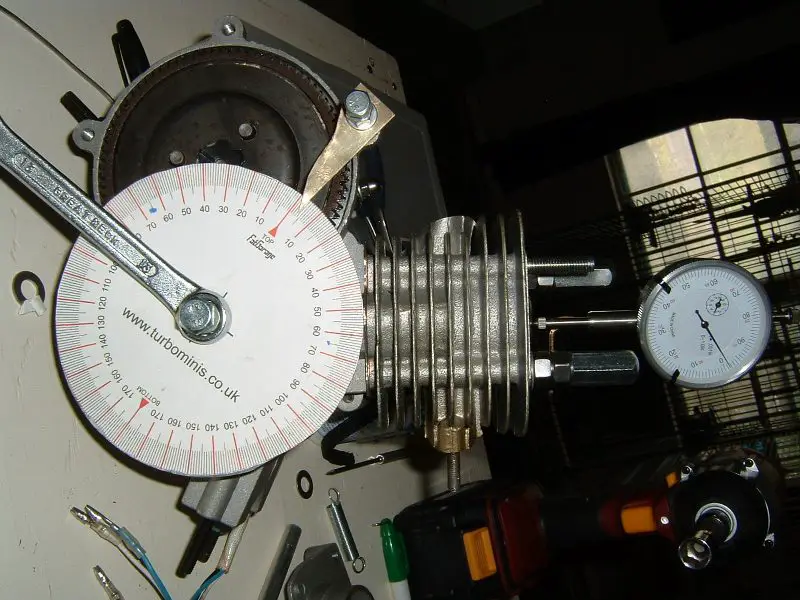

Here are some specs that basically tell what the set up in this engine is, lots of put together and tare down and repeat, but I finally wound up with what you see below.

1. head gasket thickness - .040"

2. Rectangular Transfer port Pk80 standard height jug

3. Jug Deck Height reduced .080

4. two different thickness base gaskets one is .020" and the other is .040", total base gasket thickness is 1.6mm

5. Piston has small amount of ramping on exhaust side and the skirt is notched on intake side to reveal an almost completely open port at TDC.

6. Squish clearance between piston and squish ring of Diamond head is 0.70mm

I 'm not sure when I'll have this engine on the bike and running since I'm trying to get the "Taffy Bike" farther along, I justr kept looking at those two dax GT5 type lowers sitting in the box and I want to know how they're gonna perform compared to the 40mm stroke version that I have and really like.

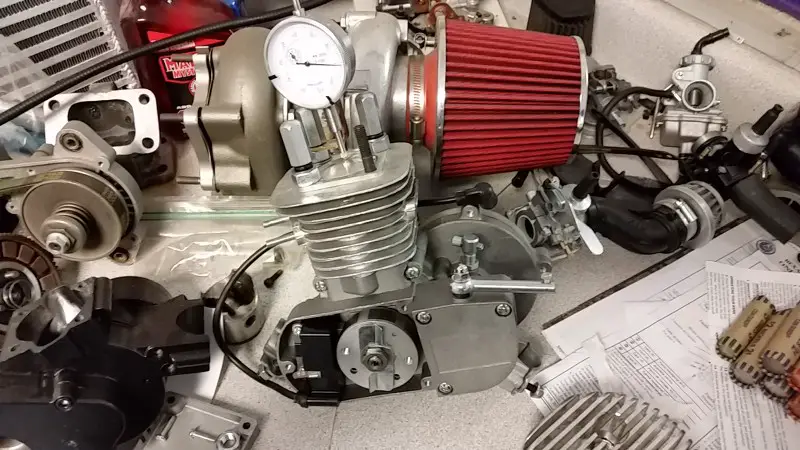

But anyway, below are a couple pix of the dax 38mm stroke I built up last week so when I have a chance I'll be doing an engine swap on one of my bikes to see how this engine is gonna feel as far as vibes go and what the overall power is gonna be.

1. head gasket thickness - .040"

2. Rectangular Transfer port Pk80 standard height jug

3. Jug Deck Height reduced .080

4. two different thickness base gaskets one is .020" and the other is .040", total base gasket thickness is 1.6mm

5. Piston has small amount of ramping on exhaust side and the skirt is notched on intake side to reveal an almost completely open port at TDC.

6. Squish clearance between piston and squish ring of Diamond head is 0.70mm

I 'm not sure when I'll have this engine on the bike and running since I'm trying to get the "Taffy Bike" farther along, I justr kept looking at those two dax GT5 type lowers sitting in the box and I want to know how they're gonna perform compared to the 40mm stroke version that I have and really like.

But anyway, below are a couple pix of the dax 38mm stroke I built up last week so when I have a chance I'll be doing an engine swap on one of my bikes to see how this engine is gonna feel as far as vibes go and what the overall power is gonna be.