What is the best route to go to change out the cheap bolts on the engine mounts? Is it better to go with a bolt into the motor or the threaded bar way? Any help is appreciated.

Changing mounting studs.

- Thread starter Beej

- Start date

I like the idea of the allen bolts, what size and length is needed for a 1 1/2 inch down tube frame?

i changed the bolts on mine today. i used high tensile steel nuts and bolts.

(6mmx25mm bolts for the carby and exhaust,6mmx50mm for the bracket)

only good for the front bracket the back needs longer, i couldnt find any.

i just bolted them into the head with some threadloc and took the ends off

with a cutting wheel on the grinder. maybe a bit over board on the carby

and exaust but everything feels strong and tight.cost 20 bucks from a hardware shop.

got some 8mm for the head but there imperial thread.

threaded bar cold be an option, im not sre on its strength qualities though.

my neighbor uses long allen bolts,they would be good to.

(6mmx25mm bolts for the carby and exhaust,6mmx50mm for the bracket)

only good for the front bracket the back needs longer, i couldnt find any.

i just bolted them into the head with some threadloc and took the ends off

with a cutting wheel on the grinder. maybe a bit over board on the carby

and exaust but everything feels strong and tight.cost 20 bucks from a hardware shop.

got some 8mm for the head but there imperial thread.

threaded bar cold be an option, im not sre on its strength qualities though.

my neighbor uses long allen bolts,they would be good to.

Use all thread, that way the studs can be locktited in. Don't ever use locktite on a bolt on these engines. I use metric 6 and 8mm grade 8.8 (the sane as US grade 5) anything stronger is overkill as the casting can't take what you can put on a grade 8.8

Double nut or nylon locking nuts all the way around. Use proper torque. 50-60 INCH pounds on 6mm and 150-204 INCH pounds on 8mm.

I have never in 5 builds, had a stud break or a stud hole strip. This is one of the mods I recommend 100% of the time as "out of the box" to do things.

Double nut or nylon locking nuts all the way around. Use proper torque. 50-60 INCH pounds on 6mm and 150-204 INCH pounds on 8mm.

I have never in 5 builds, had a stud break or a stud hole strip. This is one of the mods I recommend 100% of the time as "out of the box" to do things.

If you are referring to me...yes with studs I use RED lock tite. Using bolts I would not use RED. RED dries so well that at times you need heat to remove a fastener. Heating a stud for removal is not a problem whereas a bolt might be. I use RED on every stud.y would u tell people not to use locktite that just seems silly as i use red locktite on everything and havent had any complications yet it stops the **** from fallin off lol

Just a word of caution to anyone using the red lable Loctite: If the time comes when you need to remove that fastener, you're going to have problems. Especially if it is a steel fastener into an aluminum casting. Read the instructions that come with Loctite and it will clearly tell you that heat will be required to free the adhesion of red Loctite.

Applying too much heat to the engine case can warp or otherwise damage it. Yes, the product will keep things from loosening but there'll come a time when something needs to come apart for whatever reason and that's where the fun begins.

Loctite has other products better suited to our uses. Do a little research before using red lable Loctite.

Tom

Applying too much heat to the engine case can warp or otherwise damage it. Yes, the product will keep things from loosening but there'll come a time when something needs to come apart for whatever reason and that's where the fun begins.

Loctite has other products better suited to our uses. Do a little research before using red lable Loctite.

Tom

i have done 30 builds and have never needed to use locktite.

these are cast allm blocks and if you use excissive tightening ou will break the mounts, break off bolts or strip the holes.

using 'hard' steel bolts in the motormounts is begging for trouble.

just tighten the bolts tight enough for the motor to sit solid.... then double nut all mount nuts.

i have never had a build come loose break or strip.

stay dry

gubba

these are cast allm blocks and if you use excissive tightening ou will break the mounts, break off bolts or strip the holes.

using 'hard' steel bolts in the motormounts is begging for trouble.

just tighten the bolts tight enough for the motor to sit solid.... then double nut all mount nuts.

i have never had a build come loose break or strip.

stay dry

gubba

I'm with you, gubba on most things.i have done 30 builds and have never needed to use locktite.

these are cast allm blocks and if you use excissive tightening ou will break the mounts, break off bolts or strip the holes.

using 'hard' steel bolts in the motormounts is begging for trouble.

just tighten the bolts tight enough for the motor to sit solid.... then double nut all mount nuts.

i have never had a build come loose break or strip.

stay dry

gubba

Installed and torqued properly there is really no reason to have to use any thread locking products. Over and under tightening, improperly seated and/or damaged fasteners are the main reasons for the trouble you'll see reported here.

I will disagree with your assumption that using hardened steel fasteners will cause trouble. Grade 5 or 8 fasteners, properly torqued will not compromise the aluminum castings. Yes, over tighten them and the aluminum threads will go away but that's true with even the softer stuff. Where guys get into trouble is with ill fitting motor mounts that allow the vibration to work on the threads and fasteners resulting in something letting go eventually. With harder fasteners, its usually the castings.

Tom

Do you have anything between the down tube and the engine mount. People have found it best to have the engine mount mounted directly to the seat/down tube, this will transfer the vibration throughout the bike. On my first build I had such a vibration that my hands were numb for 30 minutes after riding 10 miles. Eventually the frame broke in two (I had drilled a hole in the frame), and had to change frames until I repaired the broke frame. When I mounted the engine on a different frame 90% of the vibration disappeared......much to my delight. Mounting procedures the same, and transferred the wheels to the second frame. Just thought I'd pass that experience along.yes i was was referring to you Al. But i think I have a poorly balanced crank as even red locktite on my 5/16 allenhead bolts still needed to be retightened a couple times now, plus thing feels like im riding a bee hive at high rpms.

HERE"S WHAT I DID:

When I first started mounting HT motors, I think i had studs crack on me 3 times. So from personal experience (not to mention the frustration and of degradation burning a hole through my wallet), I came up with a sensible solution:

First and foremost, it is absolutely without a doubt mandatory that you replace the piece of sh*t studs used to mount the engine to the frame. The studs need to be replaced with 8.8 grade steel studs. Conveniently, the head bolts sold by Sick Bike Parts are the same size as the mounting studs. I cut them down for the correct size. (I even had enough left over the replace the studs for my expansion chamber.)

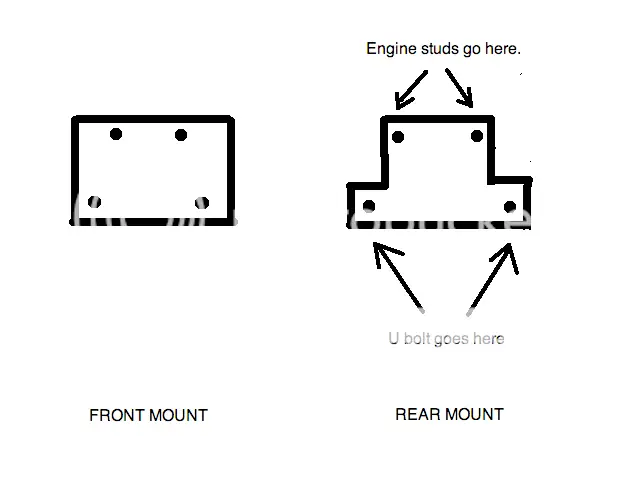

Next, I bought TWO of the U bolt mounts from Bikeberry: []Bicycle Engine Kit - Gas Powered Bicycle - Bike Motor Kit - Bicycle Engines - Grubee - Beach Cruisers - Bikeberry - BikeBerry.com

Both are used to mount the engine. The rear mounting plate had be cut down on the sides to make clearance for the chain and the clutch housing. I used an angle grinder to accomplish this. If you don't have an angle grinder, use a dremel or even a hack saw and remember to file down the ruff edges.

After you have the prep work done on the mounting plates, Your ready to mount the plates to the bike, and the engine to plates. I had to cut one of the U bolt down to size making it resemble more of a "J" to properly lighten down the the plates. Be careful not to cut too much off other wise you'll have a h*ll of time trying to get both sides of the bolt to line up correctly with the holes on the plate. Make sure that on both mounts you get both plates to make as much surface contact with the frame as possible for the least amount of vibration when riding.

And last but not least: DO NOT OVER TIGHTEN THE BOLTS USED TO FASTEN THE MOUNTING STUDS TO THE PLATE!! Use nylock nuts. No need for locktight. As an extra precaution, I left enough size/room on the mounting studs to use a regular nut to reinforce the nylock nut.

SO WHY DOES THIS WORK SO WELL?

The U Bolts take all of the pressure load off the mounting studs. Pressure paired with the vibration of the motor and the most common mistake of over-tightening nuts all spell the disaster leading to snapping studs in your block. And now you've just learned the gangsta way to properly mount.

Hope this helps you as well as some of the lurkers on the board.

RIDE SAFE.

wasabi

When I first started mounting HT motors, I think i had studs crack on me 3 times. So from personal experience (not to mention the frustration and of degradation burning a hole through my wallet), I came up with a sensible solution:

First and foremost, it is absolutely without a doubt mandatory that you replace the piece of sh*t studs used to mount the engine to the frame. The studs need to be replaced with 8.8 grade steel studs. Conveniently, the head bolts sold by Sick Bike Parts are the same size as the mounting studs. I cut them down for the correct size. (I even had enough left over the replace the studs for my expansion chamber.)

Next, I bought TWO of the U bolt mounts from Bikeberry: []Bicycle Engine Kit - Gas Powered Bicycle - Bike Motor Kit - Bicycle Engines - Grubee - Beach Cruisers - Bikeberry - BikeBerry.com

Both are used to mount the engine. The rear mounting plate had be cut down on the sides to make clearance for the chain and the clutch housing. I used an angle grinder to accomplish this. If you don't have an angle grinder, use a dremel or even a hack saw and remember to file down the ruff edges.

After you have the prep work done on the mounting plates, Your ready to mount the plates to the bike, and the engine to plates. I had to cut one of the U bolt down to size making it resemble more of a "J" to properly lighten down the the plates. Be careful not to cut too much off other wise you'll have a h*ll of time trying to get both sides of the bolt to line up correctly with the holes on the plate. Make sure that on both mounts you get both plates to make as much surface contact with the frame as possible for the least amount of vibration when riding.

And last but not least: DO NOT OVER TIGHTEN THE BOLTS USED TO FASTEN THE MOUNTING STUDS TO THE PLATE!! Use nylock nuts. No need for locktight. As an extra precaution, I left enough size/room on the mounting studs to use a regular nut to reinforce the nylock nut.

SO WHY DOES THIS WORK SO WELL?

The U Bolts take all of the pressure load off the mounting studs. Pressure paired with the vibration of the motor and the most common mistake of over-tightening nuts all spell the disaster leading to snapping studs in your block. And now you've just learned the gangsta way to properly mount.

Hope this helps you as well as some of the lurkers on the board.

RIDE SAFE.

wasabi

Last edited:

Yes I trash ALL OEM hardware. The cylinder studs are made out of the same junk, and in most cases are 8mm studs not the 6mm that the engine mount uses. Along with you stated the most important thing to remember is to mount the engine mounts on the tubes as perfectly as you can. Space between the mount and tube is a major cause of broken studs, stripped threads and cracked cases.

Also 6mm studs are torqued to 50-70 INCH pounds and 8mm 150-200 INCH pounds. I have used 50 and 150 on all my builds without issues.

Also 6mm studs are torqued to 50-70 INCH pounds and 8mm 150-200 INCH pounds. I have used 50 and 150 on all my builds without issues.

Thanks for the info on the torque specs.Yes I trash ALL OEM hardware. The cylinder studs are made out of the same junk, and in most cases are 8mm studs not the 6mm that the engine mount uses. Along with you stated the most important thing to remember is to mount the engine mounts on the tubes as perfectly as you can. Space between the mount and tube is a major cause of broken studs, stripped threads and cracked cases.

Also 6mm studs are torqued to 50-70 INCH pounds and 8mm 150-200 INCH pounds. I have used 50 and 150 on all my builds without issues.