Well in having conversation with a very knowledgeable guy in this hobby he told me that these engines with the cranks marked ZAE50 are the best of the cranks in these engines, they're normally the most true and the best balanced of all of the cranks out there, the engine do require a few tweaks here and there to get lined up properly, but make the best overall engines.

I found the lower of this engine to look excellent and it has one of the better looking pistons that is marked with a # 2 on top with an arrow opposite it on the other side.

What I found I do not like about the particular engine I got is the Jug/cylinder.

It is the worst I have even had as far as the ports are concerned all of the ports are the smallest I have seen on any jug I have ever had, other than that it looks OK, but no way I think this jug could be made into a great performer very easily, it would take a lot of grinding just to get it equal with most of the others I've seen before they had anything done to them, ports are fairly clean but just very small, I know the larger counter weights in these HB engines cause them to have higher crank case pressure/primary compression and that may help force the charge through these small transfers but the intake and exhaust ports being so narrow is going to really limit the rpm potential.

I'm gonna do some work on these just to get them cleaned better and I will likely widen them some and grind a radius in the narrow side corner of the transfers so the air/fuel charge wont be slamming into a blunt surface when it leaves the case headed fro the combustion chamber, maybe that will help it breathe a little better for good mid range power and torque and let it wind up a little better on the top end also.

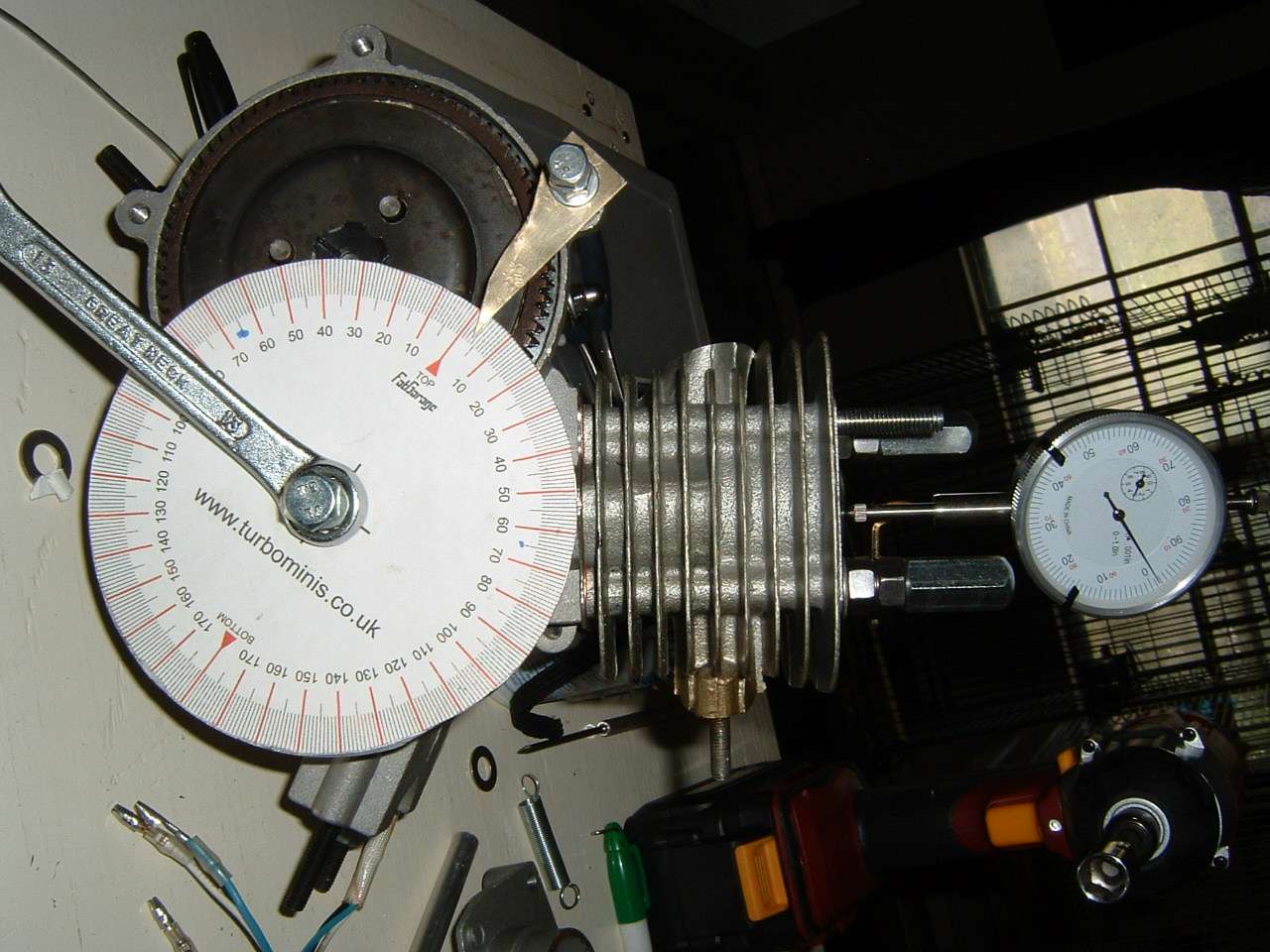

Pics show what I'm talking about with these tiny ports.

Map

I found the lower of this engine to look excellent and it has one of the better looking pistons that is marked with a # 2 on top with an arrow opposite it on the other side.

What I found I do not like about the particular engine I got is the Jug/cylinder.

It is the worst I have even had as far as the ports are concerned all of the ports are the smallest I have seen on any jug I have ever had, other than that it looks OK, but no way I think this jug could be made into a great performer very easily, it would take a lot of grinding just to get it equal with most of the others I've seen before they had anything done to them, ports are fairly clean but just very small, I know the larger counter weights in these HB engines cause them to have higher crank case pressure/primary compression and that may help force the charge through these small transfers but the intake and exhaust ports being so narrow is going to really limit the rpm potential.

I'm gonna do some work on these just to get them cleaned better and I will likely widen them some and grind a radius in the narrow side corner of the transfers so the air/fuel charge wont be slamming into a blunt surface when it leaves the case headed fro the combustion chamber, maybe that will help it breathe a little better for good mid range power and torque and let it wind up a little better on the top end also.

Pics show what I'm talking about with these tiny ports.

Map

Attachments

-

108.2 KB Views: 450

-

224.1 KB Views: 399

-

188.9 KB Views: 459

-

204 KB Views: 403

-

183.7 KB Views: 399

you need to get the half breed engine from freds cr machine i am totaly impressed about his porting job on them and the addition of the two boost ports

you need to get the half breed engine from freds cr machine i am totaly impressed about his porting job on them and the addition of the two boost ports