Well that is just silly, I use all kinds of switches on my motorized bicycles and many other things and they all work as intended, if the 'slightest vibration makes them fail' is the problem you have then either your bike vibrates like an unbalanced blender or you are using Wallmart quality switches.KC, the problem switches is that with the slightest is vibration you lose contact which in turn will cause a erotical performance and possible engine damage. It's been tried before.

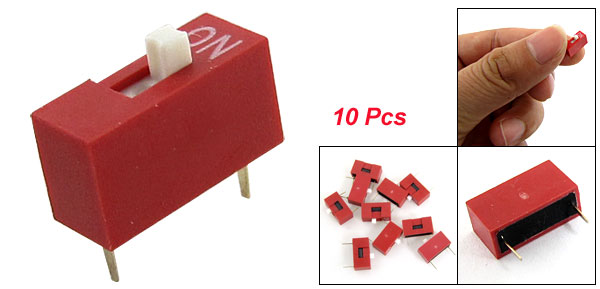

I use quality switches be it toggle, DIP or Keylock and after 30 years of dinking with little PC Motherboard jumpers I'll use DIP switches like this, 10 for $6, when I build mine.

I am regretting throwing out all of my PC board making equipment (except the drill press, tiny drill bits and black light) when I moved as I had everything for photo-etching PCB's and made over 100 little devices from my own PC design to finished product.

It's not cheap to get started nor easy to do, and it's messy, especially the etching solvent as it is designed to eat copper so it eats everything it touches.

Not worth it for the hobbyist to make one item but well worth it if you want to build 50 or more a year of something as you can lay out several on a sheet of copper covered PCB and etc a few all at once and cut them out and drill 'em.

Last edited: