I have a skyhawk engine which I finally got running. After it starts and runs for about 15 to 30 seconds, the chain comes off of the rear sprocket. It seems that the engine actually tilts to the left (sprocket side), which causes the chain to be out of line between the engine sprocket and the rear sprocket. Does anyone have an idea why this happens and how to keep the engine from tilting? Everything seems to be tight, but it keeps happening. It almost seems like the rear clamp mount on the engine has a problem where it is connected to the engine itself. Has anyone ever had the mount break up inside the engine?

Chain keeps falling off sprocket

- Thread starter whitebright

- Start date

The engine must be straight up & down in the frame!

Also, the rear sprocket must spin as close to perfect as possible... No side to side wobble & centered with the axle.

Then make sure the chain tensioner is feeding the chain straight onto the sprocket without it snagging on the sprocket teeth.

Also, the rear sprocket must spin as close to perfect as possible... No side to side wobble & centered with the axle.

Then make sure the chain tensioner is feeding the chain straight onto the sprocket without it snagging on the sprocket teeth.

The rear sprocket does spin doesn't wobble and the tensioner is good. It is the engine that seems to move after the motor starts running for a few seconds. How do I keep the motor from moving. That seems to be the real problem. After you ride down the street 100 yards or so, the chain comes off and the motor has tilted, which has caused the chain to be out of line between the front and rear sprockets.

How are you mounting the motor? Ubolts? Can you take some pics of the mounts?

Take the nuts off, and check they stud isn't threaded.

Take the nuts off, and check they stud isn't threaded.

i am having the exact same prtoblem with mine everything is very tight but it strill moves thing ticks me off and the chain will not stay on, where did you get yours from

We really need to see some pictures of your mounts. If done properly there is really no way the engine can "tilt" if the mounts are tight against the frame and all the fasteners are intact. You're not mounting in rubber, are you? Or some other resilient material? The engine needs to be solid to the frame. Post a couple of close ups of your engine mounts and we'll take a look.

Tom

Tom

Last edited:

hey ive been through this and asked about options for this problem here.....the chain you guys are running is 410....the tensioner pully is meant for 415 chain....thats why the tensioner pully is so much wider than the chain.....ive had good luck with moving the tensioner as far away from the rear gear as possible so that the chain floating back and forth doesnt make it derail....grinding the square corners off of the drive gear helps too....dont let this beat you youll get it...you just got a hard size chain to work with

Add a muffler strap to hold muffler and engine tight to frame.

And check your mount studs and make sure they didn't come out.

And check your mount studs and make sure they didn't come out.

Try gasket paper under the motor mounts, wrap the frame a couple times if possible. Think of it like driving a car with bare rims verses tires, it'l give your mounts "traction".

Clean the frame & the mounts also if there's any grease or a lot of crud on/under them, but make sure it's dry before you set it up.

If you don't have gasket paper, then cut a piece of an old tire tube. It work work quite as well but it's better than nothing.

If you notice the engine starting to vibrate separate from the bike frame, then remove a layer or do whatever it takes to make a thinner layer of squishy stuff. The motor vibrating separately from the frame could result in the chain moving around too much, more vibration feeling, or motor mount studs snapping from bending back and fourth as the bouncing motor vibrates against the stationary frame. Learned that the hard way...

Clean the frame & the mounts also if there's any grease or a lot of crud on/under them, but make sure it's dry before you set it up.

If you don't have gasket paper, then cut a piece of an old tire tube. It work work quite as well but it's better than nothing.

If you notice the engine starting to vibrate separate from the bike frame, then remove a layer or do whatever it takes to make a thinner layer of squishy stuff. The motor vibrating separately from the frame could result in the chain moving around too much, more vibration feeling, or motor mount studs snapping from bending back and fourth as the bouncing motor vibrates against the stationary frame. Learned that the hard way...

Last edited:

I don't know if this is the same problem I had, but it sounds similar to a problem I had with the stock sprocket (44) and the 36 I bought.

Obviously, in an ideal setup, the chain would run perfectly straight from the motor to the rear sprocket. This is not always an easy task due to the near infinite amount of differences in engine kits, sprockets, bike frames and whatever other variables that could make a perfectly straight chain path difficult (or impossible).

After my kit was installed, but before I rode my bike anywhere, I lifted the back wheel and started pedaling the cranks with my hand. (while the bike was leaning on my kickstand) Immediately I noticed that every few seconds or so, the chain would make a loud snapping sound. The sound was coming from the chain not grabbing the sprocket teeth on center (so it would not seat properly on the teeth) and when the tension got high enough as the link would go around the sprocket, the rest of the chain behind the link would violently snap back on the sprocket. There was NO way I was going to fire it up with the chain acting like that. I didn't even pedal ride it anywhere.

However, after a quick investigation I realized that it was happening because the sprocket teeth are hard edged and very squared off. What I did was, I took a dremel tool and made ALL the teeth pointed (Instead of square edged) so that it would be impossible for the chain to grab the edge of the tooth and as a result the chain has a FAR easier task of sliding properly onto the sprocket teeth. After doing that, it COMPLETELY solved the problem with the chain. In fact it may have even reduced the amount of friction the chain experiences as it goes around the sprocket.

Something to try...

BARRY

Obviously, in an ideal setup, the chain would run perfectly straight from the motor to the rear sprocket. This is not always an easy task due to the near infinite amount of differences in engine kits, sprockets, bike frames and whatever other variables that could make a perfectly straight chain path difficult (or impossible).

After my kit was installed, but before I rode my bike anywhere, I lifted the back wheel and started pedaling the cranks with my hand. (while the bike was leaning on my kickstand) Immediately I noticed that every few seconds or so, the chain would make a loud snapping sound. The sound was coming from the chain not grabbing the sprocket teeth on center (so it would not seat properly on the teeth) and when the tension got high enough as the link would go around the sprocket, the rest of the chain behind the link would violently snap back on the sprocket. There was NO way I was going to fire it up with the chain acting like that. I didn't even pedal ride it anywhere.

However, after a quick investigation I realized that it was happening because the sprocket teeth are hard edged and very squared off. What I did was, I took a dremel tool and made ALL the teeth pointed (Instead of square edged) so that it would be impossible for the chain to grab the edge of the tooth and as a result the chain has a FAR easier task of sliding properly onto the sprocket teeth. After doing that, it COMPLETELY solved the problem with the chain. In fact it may have even reduced the amount of friction the chain experiences as it goes around the sprocket.

Something to try...

BARRY

wow this really works! thanks volt9. i never thought of that, considering ive hade the chain-poping problem before, this totally sloves it.

Sounds like your mounts aren't getting a good grip on the mounting surface.What size motor are you running?I only use Grubee 80's.If you wrap rubber around the seat post you have to make sure your motor-mount matches that diameter if not your going to have 2 contact points on the motor side of the clamp.I don't use any thing between the mount and seat tube and make sure the motor mount matches the seat tube.I add a 1/4" strip of neoprene rubber between the motor mount and the motor.

For the front I don't drill the frame.I just use longer bolts,allen head.if the bolts wont thread straight into the motor I dimple the frame on each side untill they will.Then I measure the space between the motor and frame and make a rubber "motor mount" spacer out of a hockey-puck.Then I make sure I tighten both front and rear evenly alternating from front to rear.Make sure if you try what I do on the front that your front bolts thread into the case almost all the way before they bottom out.I also use green lock-tite on everything after assy.Hope this helps.Kip.

For the front I don't drill the frame.I just use longer bolts,allen head.if the bolts wont thread straight into the motor I dimple the frame on each side untill they will.Then I measure the space between the motor and frame and make a rubber "motor mount" spacer out of a hockey-puck.Then I make sure I tighten both front and rear evenly alternating from front to rear.Make sure if you try what I do on the front that your front bolts thread into the case almost all the way before they bottom out.I also use green lock-tite on everything after assy.Hope this helps.Kip.

OOPsie didn't read the second page before I posted.Good to hear you fixed your problem.I take my sprockets and hold them flat overhanging my bench and take a couple of laps around them with my 50 grit hand grinder on both sides.Then I take my die-grinder and soften the edges of each tooth.Kip.

^ The man knows what he's talking about. Any soft mount attempt will only promote movement, not lessen it. Even if you've managed to get it secure enough to not have perceivable lateral movement - all you've done is transfer the mount stresses from the mounts themselves to just the fasteners - which given time may strip/sheer or otherwise fail. Additionally, no matter the soft material it will compress & degrade with time from the pressure & vibration, resulting in either constant re-torquing (also promotes fastener failure) and/or mount sheer.We really need to see some pictures of your mounts. If done properly there is really no way the engine can "tilt" if the mounts are tight against the frame and all the fasteners are intact. You're not mounting in rubber, are you? Or some other resilient material? The engine needs to be solid to the frame. Post a couple of close ups of your engine mounts and we'll take a look.

Tom

Think about it... squishy = wiggly, right?

Mount your engine solidly or you will cause yourself problems down the road....like the engine "tipping sideways" or "coming loose".

This is a ole thread but this post can be used if searched.The rear sprocket does spin doesn't wobble and the tensioner is good. It is the engine that seems to move after the motor starts running for a few seconds. How do I keep the motor from moving. That seems to be the real problem. After you ride down the street 100 yards or so, the chain comes off and the motor has tilted, which has caused the chain to be out of line between the front and rear sprockets.

DO NOT over tighten, meaning over torque. 6mm studs are to be torqued 50 - 70 INCH POUNDS NO more. If you upgraded the studs a grade 8.8 can take more torque then the threads in this cast aluminum can stand.

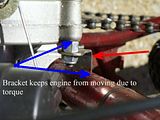

This will keep the engine from moving on the tubes due to engine torque.

Last edited:

Ron,Is that bracket welded to the seat tube? I don't see how it could stop the motor from turning left if it isn't.Kip.

Believe it or not....NO. With the "L" bracket installed where I have it I have absolutely NO engine movement to the left. I torque 6mm studs to between 50 and 60 inch pounds, no more, with this yes the engine will shift to the left. This is all I feel the cast aluminum can take safely without putting a undue stress on the threads. Another key to engine mounting hardware stability (studs, threads, mounts) is to have as near as a perfect fit in the frame. A perfect fit will be a 75 degree "V".Ron,Is that bracket welded to the seat tube? I don't see how it could stop the motor from turning left if it isn't.Kip.

Try it, you'll like it. Cheap and easy.

Last edited: