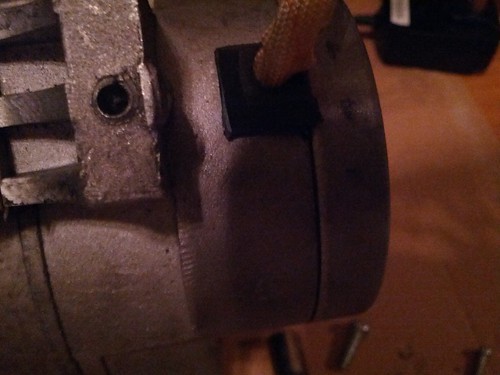

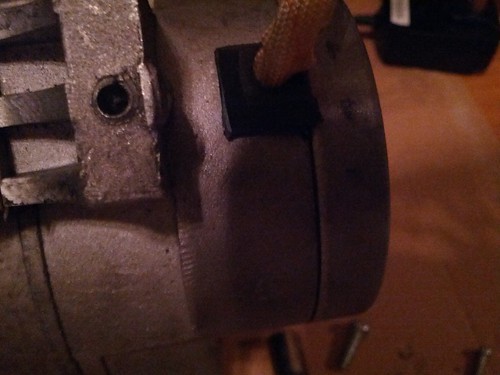

So I was a newbie and decided to loctite the mount studs (stock chinese studs) and used way to much loctite and ended up hydro-locking the stud which caused the stud to snap. I tried using a left handed drill bit and it didn't grab. So then I tried using an easy out but it also doesn't grab. I turn the bit and nothing happens except I make the hole a little bigger. So I need to look into other options. I was wondering if I could jb weld a smaller bolt in the whole I made in the stud and and try to take it out that way? I've never used jb weld and wonder if it would be strong enough to handle the job. Or should I try and have someone tack weld a smaller bolt in the whole I made to get it out? I figure if jb weld works it would be cheaper. It snapped flush with motor also, pic included. Any advice is appreciated.