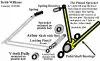

I have just come in from a very successful shop session and feel higher than a kite. I was working on my Monark with the 3-speed jackshaft and ideas kept flooding my mind. I glanced at a pair of Motobecane rear coilovers and rear suspension came to mind. Most of what I have seen attempted didn't pay much attention to chain slacking as it swings. Try this---Take the crank out and find some bearings to replace the crappy peddle ones, maybe some with snap ring grooves can be found. Anyway, pass a straight shaft through and put some flats on it to bolt lightweight-style peddle arms parallel to each other using the wedge bolts Slip tubing over them and weld for a swingarm.

Outboard of this, a sprocket to drive the rear wheel and a pulley from the motor belt on a bearing arbor rotating on the swing arm shaft. The chain will always be at constant adjustment. To go fancier, use needle bearings and run the swing arm off the small shaft and put the engine drive in one side and the sprocket on the other on a rotating tube containing the swing arm shaft. You could use a derailleur system if you wished. The upper rear fork would be a front fork with a valve spring sliding in and out of a pivoting receiver behind the seat post. A milled slot in the fork would control its travel limits with a pin or perhaps simply use the fork nut in a pivoting yoke to limit the retreat of the fork stem. It would require pivot bolts at its connection with the swing arm. This system would eliminate any side wobble in the rear wheel. So much for that. Here's what I accomplished. The Hodaka tank I mounted has 2 fuel cocks and I intended to simply wye them together and run to the carb through a filter. Fine, but one cock barb was about 1/8" from the muffler, which attaches at a funny angle, so I pulled the muffler to see if I could invert it. Nope, it interfered with the 2nd jackshaft, and also the engine port is a D shape and somewhat larger than the round muffler flange. AHA Back Pressure! I made a 1/4" thick plate and used some 1-1/4" trampoline support with small radii bends to fashion an exhaust pipe.

It didn't come easy. I shaped the D in the end and inserted halfway into the flange and welded inside so as not to interfere with flange nuts. I discovered my Roto Zip that I have learned to despise for its difficulty in controlling, is a pretty darn good die grinder with the 1/4" chuck and a carbide burr. My air situation sucks anyhow so this is a real blessing for me. I cleaned up my internal bead in short order. With my oxygen cylinder's dying gasp I managed to crank all the necessary bends into the pipe. I used the old trick for fitting expansion chambers to racer frames. Cut a pie slice out of one side ALMOST through and a straight cut on the opposing side. Bend the pie slice closed with torch and insert and weld the cut out in the other side. Brought back many memories of the endless line of racers wanting chambers made and fitted. I am as good as I ever was, and that feels good. Tomorrow or whenever I get oxy I will finish my welding and scarf the pipe at a sexy angle..

I still need to make a chop saw cut and bend it up parallel to the ground. THEN I can paint it with BBQ grille rattlecan and make the simple little wye fuel connection I set out to do tonight. If I ever feel flush, it might get chromed or maybe silver baked manifold paint. I have an idea the changes are going to wake up the kitty One last thing-The Roto Zip IS useful for one thing--With a radius rod attached you can cut huge round holes in sheet metal from a pivot.

Also the word is SEALING wax, not candlewax. I know better but it is impossible to edit a title once posted.

Outboard of this, a sprocket to drive the rear wheel and a pulley from the motor belt on a bearing arbor rotating on the swing arm shaft. The chain will always be at constant adjustment. To go fancier, use needle bearings and run the swing arm off the small shaft and put the engine drive in one side and the sprocket on the other on a rotating tube containing the swing arm shaft. You could use a derailleur system if you wished. The upper rear fork would be a front fork with a valve spring sliding in and out of a pivoting receiver behind the seat post. A milled slot in the fork would control its travel limits with a pin or perhaps simply use the fork nut in a pivoting yoke to limit the retreat of the fork stem. It would require pivot bolts at its connection with the swing arm. This system would eliminate any side wobble in the rear wheel. So much for that. Here's what I accomplished. The Hodaka tank I mounted has 2 fuel cocks and I intended to simply wye them together and run to the carb through a filter. Fine, but one cock barb was about 1/8" from the muffler, which attaches at a funny angle, so I pulled the muffler to see if I could invert it. Nope, it interfered with the 2nd jackshaft, and also the engine port is a D shape and somewhat larger than the round muffler flange. AHA Back Pressure! I made a 1/4" thick plate and used some 1-1/4" trampoline support with small radii bends to fashion an exhaust pipe.

It didn't come easy. I shaped the D in the end and inserted halfway into the flange and welded inside so as not to interfere with flange nuts. I discovered my Roto Zip that I have learned to despise for its difficulty in controlling, is a pretty darn good die grinder with the 1/4" chuck and a carbide burr. My air situation sucks anyhow so this is a real blessing for me. I cleaned up my internal bead in short order. With my oxygen cylinder's dying gasp I managed to crank all the necessary bends into the pipe. I used the old trick for fitting expansion chambers to racer frames. Cut a pie slice out of one side ALMOST through and a straight cut on the opposing side. Bend the pie slice closed with torch and insert and weld the cut out in the other side. Brought back many memories of the endless line of racers wanting chambers made and fitted. I am as good as I ever was, and that feels good. Tomorrow or whenever I get oxy I will finish my welding and scarf the pipe at a sexy angle..

I still need to make a chop saw cut and bend it up parallel to the ground. THEN I can paint it with BBQ grille rattlecan and make the simple little wye fuel connection I set out to do tonight. If I ever feel flush, it might get chromed or maybe silver baked manifold paint. I have an idea the changes are going to wake up the kitty One last thing-The Roto Zip IS useful for one thing--With a radius rod attached you can cut huge round holes in sheet metal from a pivot.

Also the word is SEALING wax, not candlewax. I know better but it is impossible to edit a title once posted.

Last edited:

The HT

The HT is no longer a candidate, but I have a 6ft. version of the Atlas Van Lines unlimited hydro with the Allyson V-12 that has a backward turning Quadra 2.2ci. with 2.2hp and a rope starter that was WAY inadequate for the boat. Been waiting for a butt-kickin' chainsaw to come along I could upgear with Gilmer pulleys and belt. I don't want to get started with 1/4 scale boats. Anyhow, I can put the necessary sprocketing in the front shaft hanger and use that engine Also there is a Kawasaki snow blower mill that I stuck a weed eater centrifugal clutch on that also has a rope starter. It was too rpm limited for the 1/4 scale Crackerbox boat. About 32 cc. At least it's cute.

is no longer a candidate, but I have a 6ft. version of the Atlas Van Lines unlimited hydro with the Allyson V-12 that has a backward turning Quadra 2.2ci. with 2.2hp and a rope starter that was WAY inadequate for the boat. Been waiting for a butt-kickin' chainsaw to come along I could upgear with Gilmer pulleys and belt. I don't want to get started with 1/4 scale boats. Anyhow, I can put the necessary sprocketing in the front shaft hanger and use that engine Also there is a Kawasaki snow blower mill that I stuck a weed eater centrifugal clutch on that also has a rope starter. It was too rpm limited for the 1/4 scale Crackerbox boat. About 32 cc. At least it's cute.

The vertical tube holds a goose neck from a BMX bike that has 4 Allen bolts holding the bars. This will hold my foot bar. I saw some 1" hand grips for a wheelbarrow somewhere. I can reverse it to shift the bar position. If I use a 3-speed rear hub, it will freewheel and I can't start an HT. That's OK, I have lots of ripcord engines anyhow. This also leaves the possibility of a split spring-loaded pulley from an AC treadmill with an idler pulley to vary the speed with a centrifugal clutch on the engine. I can either do it ala 1910 with a big cobby lever and ratchet teeth to hold the setting, or use a rocker heel-toe peddle like an old

The vertical tube holds a goose neck from a BMX bike that has 4 Allen bolts holding the bars. This will hold my foot bar. I saw some 1" hand grips for a wheelbarrow somewhere. I can reverse it to shift the bar position. If I use a 3-speed rear hub, it will freewheel and I can't start an HT. That's OK, I have lots of ripcord engines anyhow. This also leaves the possibility of a split spring-loaded pulley from an AC treadmill with an idler pulley to vary the speed with a centrifugal clutch on the engine. I can either do it ala 1910 with a big cobby lever and ratchet teeth to hold the setting, or use a rocker heel-toe peddle like an old  KW

KW