Hey everyone,

I have been having some issues with my HS 49cc for the past few weeks, and today I think my engine is finally toast.

Background:

A few days ago I was riding like I always do, when suddenly I heard a rattling noise. I stopped to investigate, and everything was tightened down, so I started it up again. When it was idling, I heard the noise again coming from inside and the engine was showing signs of overheating. I immediately killed the engine and pushed my bike back to my house.

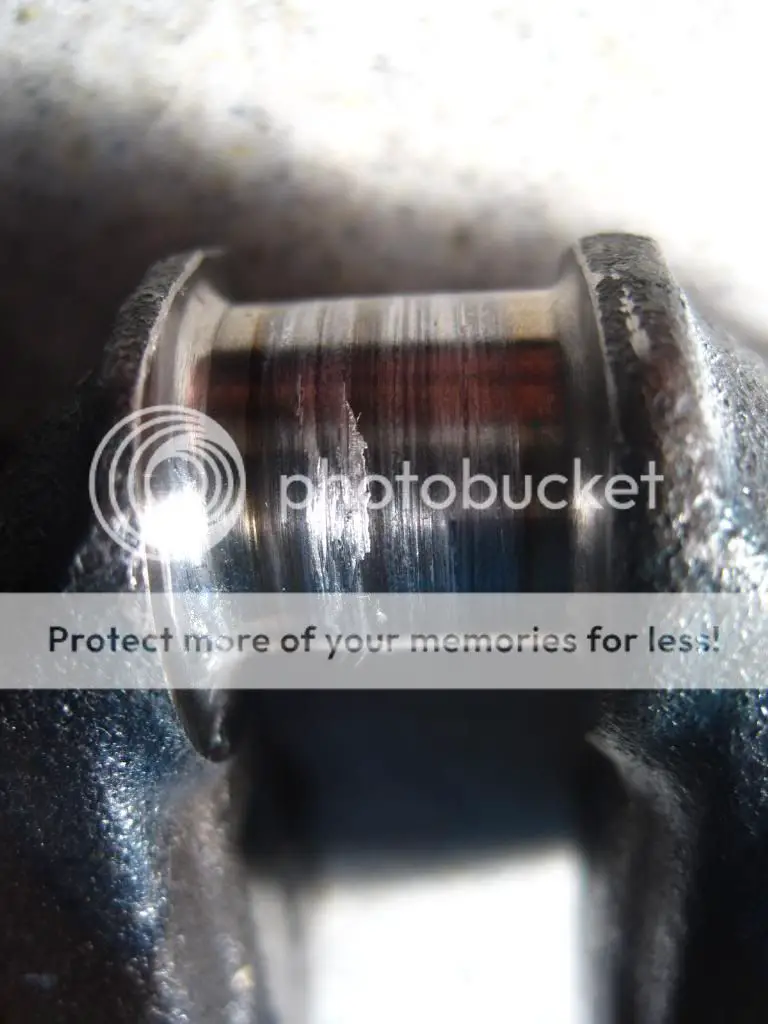

I tore open the engine after it was cool and just as I suspected, the oil slinger had broken off. I inspected the rest of the engine and it was all in perfect shape. I could still even see the crosshatch marks on the cylinder walls from when it was honed. I cleaned it all anyways with purple cleaner, rinsed each part multiple times with water, then stuck them in the oven to dry off. I put all the parts back together, using generous amounts of royal purple motor oil on each part as I put them back together. I then resealed the crankcase and let it dry for a day.

The next day, I started it up on my bench and It ran really well. It revved up fast and sounded beautiful. I stuck it on my bike and made sure everything was aligned and tightened, then took it for a ride. The engine was bogging a bit, so I put it on the stand and screwed in the idle screw so it would run by itself then adjusted the tuning screw for the highest idle speed (this is the method that Phantom Bikes told me to use to tune it, and it has worked in the past).

Problem:

While tuning it the last time, a bunch of white smoke started to fly out of the oil catch and the engine was going down in RPMs. I killed it and looked it over, and the engine was steaming. I thought it was residual oil from when I put it back together, so I started it up again. After 5 more seconds, the engine cut off and I can no longer turn it over. I removed the oil plug and the oil is a clean purple color with no foreign substances in it. The thing is that in another member's thread about the oil slinger, it was said that its not needed due to the big plastic gear that fings oil everywhere. If this engine is dead, then im just gonna build a 79cc predator bike instead but I would love to save this one if possible.

Thanks guys,

Chris N.

I have been having some issues with my HS 49cc for the past few weeks, and today I think my engine is finally toast.

Background:

A few days ago I was riding like I always do, when suddenly I heard a rattling noise. I stopped to investigate, and everything was tightened down, so I started it up again. When it was idling, I heard the noise again coming from inside and the engine was showing signs of overheating. I immediately killed the engine and pushed my bike back to my house.

I tore open the engine after it was cool and just as I suspected, the oil slinger had broken off. I inspected the rest of the engine and it was all in perfect shape. I could still even see the crosshatch marks on the cylinder walls from when it was honed. I cleaned it all anyways with purple cleaner, rinsed each part multiple times with water, then stuck them in the oven to dry off. I put all the parts back together, using generous amounts of royal purple motor oil on each part as I put them back together. I then resealed the crankcase and let it dry for a day.

The next day, I started it up on my bench and It ran really well. It revved up fast and sounded beautiful. I stuck it on my bike and made sure everything was aligned and tightened, then took it for a ride. The engine was bogging a bit, so I put it on the stand and screwed in the idle screw so it would run by itself then adjusted the tuning screw for the highest idle speed (this is the method that Phantom Bikes told me to use to tune it, and it has worked in the past).

Problem:

While tuning it the last time, a bunch of white smoke started to fly out of the oil catch and the engine was going down in RPMs. I killed it and looked it over, and the engine was steaming. I thought it was residual oil from when I put it back together, so I started it up again. After 5 more seconds, the engine cut off and I can no longer turn it over. I removed the oil plug and the oil is a clean purple color with no foreign substances in it. The thing is that in another member's thread about the oil slinger, it was said that its not needed due to the big plastic gear that fings oil everywhere. If this engine is dead, then im just gonna build a 79cc predator bike instead but I would love to save this one if possible.

Thanks guys,

Chris N.