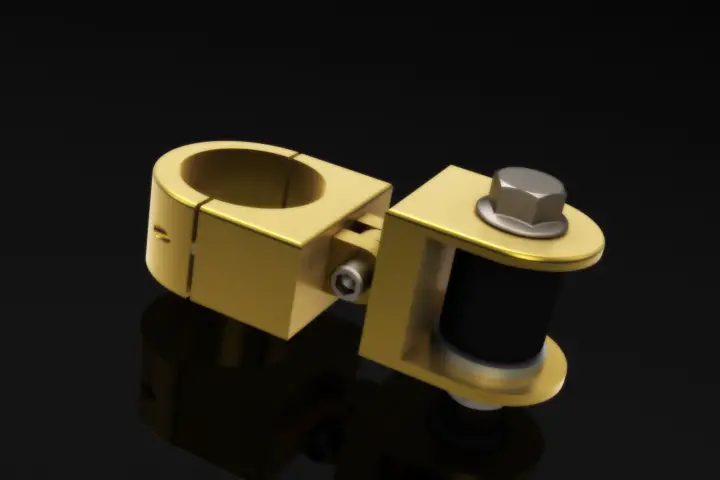

Yea we originally got the idea of using a bushing from yours and the riddley. But unfortunately from what i understand you do not make these for production, and the riddley is only for felts. The manic mechanic mount mostly unavailable as well. As you can see, besides the bushing, ours is completely different any of the available mounts. You guys should be thankful for people offering custom-made parts with this level of quality in mind.

There's some... defensiveness here I think perhaps based on a misunderstanding...

We as staff support the free and open exchange of ideas, it's the very point of this forum. We've no interest at all in

product promotion - we're naught but flattered should members choose to copy and even improve on anything we manage to develop, where it otherwise - we'd not share such ideas lol, we'd be selling them too.

I suspect Tom was simply noting what you initially neglected to mention, that your new product was inspired by R&D made here and elsewhere, a minor point you quickly clarified. While it's true we share our ideas primarily for the DIYer, such a simple item so easily made if you've access to the equipment was bound to be copied and offered to the public as a product for those without such access.

We are thankful for quality custom made parts, they assist greatly those that cannot fabricate their own, or whom would choose not to for the ease and simplicity of simply purchasing one. However, do bear in mind that we will

always favor the innovator for their creativity, vendor, staff and member alike - but most particularly those whom would freely share with no profit in mind beyond simply helping others. When a vendor recognizes it's a marketable product it's simple courtesy to acknowledge the source - particularly if the vendor in question has made little other contribution to this site, even if just through crosslink or reference on theirs.

Thread moved to

Swap And Shop as per our

rules.