edit... this thread contains detailed info on the correct insallation and modifacation off the 70cc puch hi hi head.

okay I just ordered the 70 CC pUch hi hi head from treatLand.

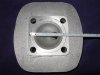

I am currently running the stock angle fire head milled down to a 6cc combustion chamber With no squish band ... it got milled off wile decking down the head and reshaping the chamber to a single hemi sphere.

With a 6 cc head on a 66cc gt5 i was at 11:1 comp uncorrected. Roughly. The results were a dramatic Increase in power everywhere, especialy. The midrange . I liked the increase in power a lot but i know that with a head that has a proper squish band and Large cooling fins with a single dome and strait plug will be even better!!! So i gave in and ordered a puch 70 cc hi hi . I plan on doing a full review of the head vs my stock rechambered head with pictures comparisons and all. I think i will run the hi hi with a single stock head gasket and see how she goes for a day. Any way pics when it arrives in the mail and a review of price quality and instalation.

More to come.

okay I just ordered the 70 CC pUch hi hi head from treatLand.

I am currently running the stock angle fire head milled down to a 6cc combustion chamber With no squish band ... it got milled off wile decking down the head and reshaping the chamber to a single hemi sphere.

With a 6 cc head on a 66cc gt5 i was at 11:1 comp uncorrected. Roughly. The results were a dramatic Increase in power everywhere, especialy. The midrange . I liked the increase in power a lot but i know that with a head that has a proper squish band and Large cooling fins with a single dome and strait plug will be even better!!! So i gave in and ordered a puch 70 cc hi hi . I plan on doing a full review of the head vs my stock rechambered head with pictures comparisons and all. I think i will run the hi hi with a single stock head gasket and see how she goes for a day. Any way pics when it arrives in the mail and a review of price quality and instalation.

More to come.

Last edited: