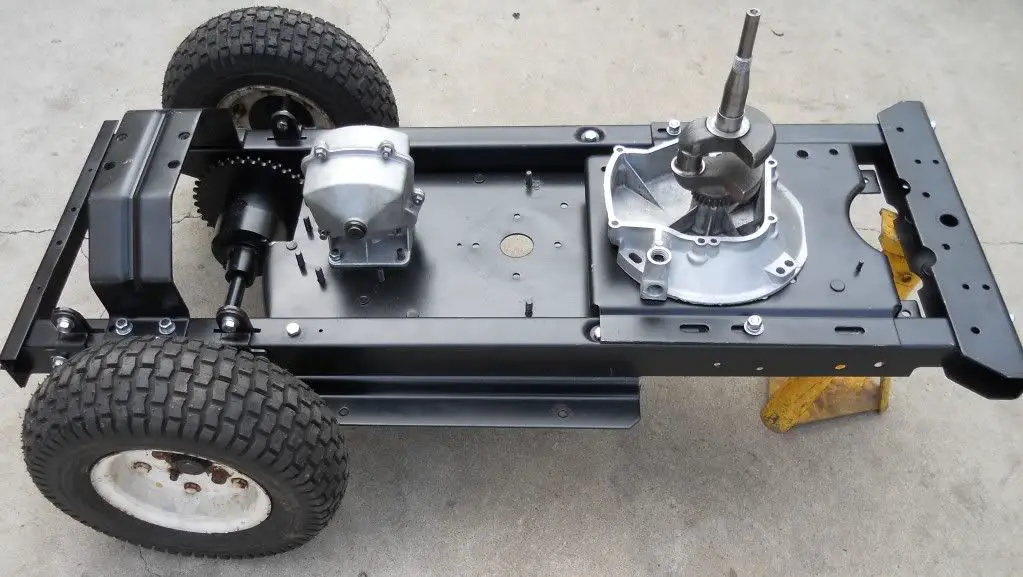

Basically starting out with a garden tractor as the foundation.

Stripped all the non essential parts and sheet metal off. Just left enough to test drive.

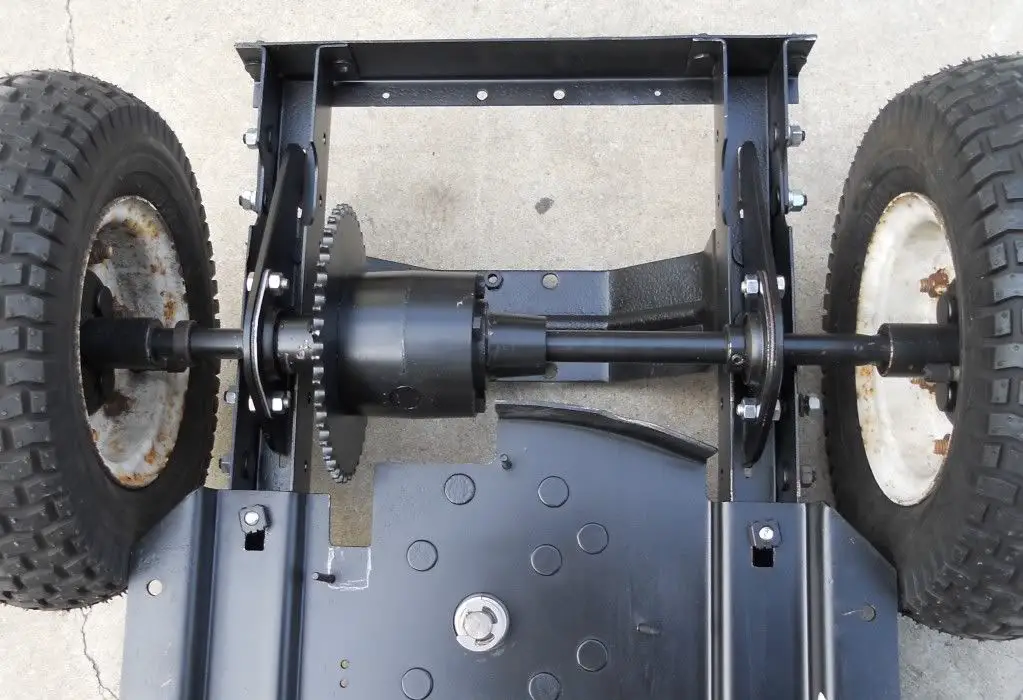

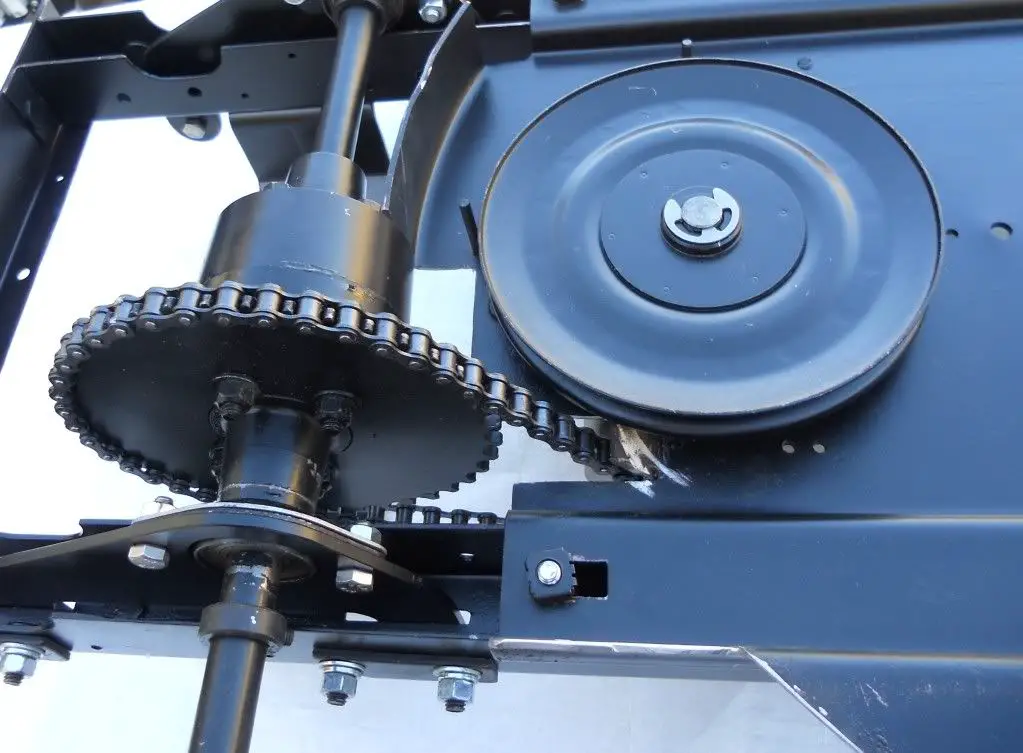

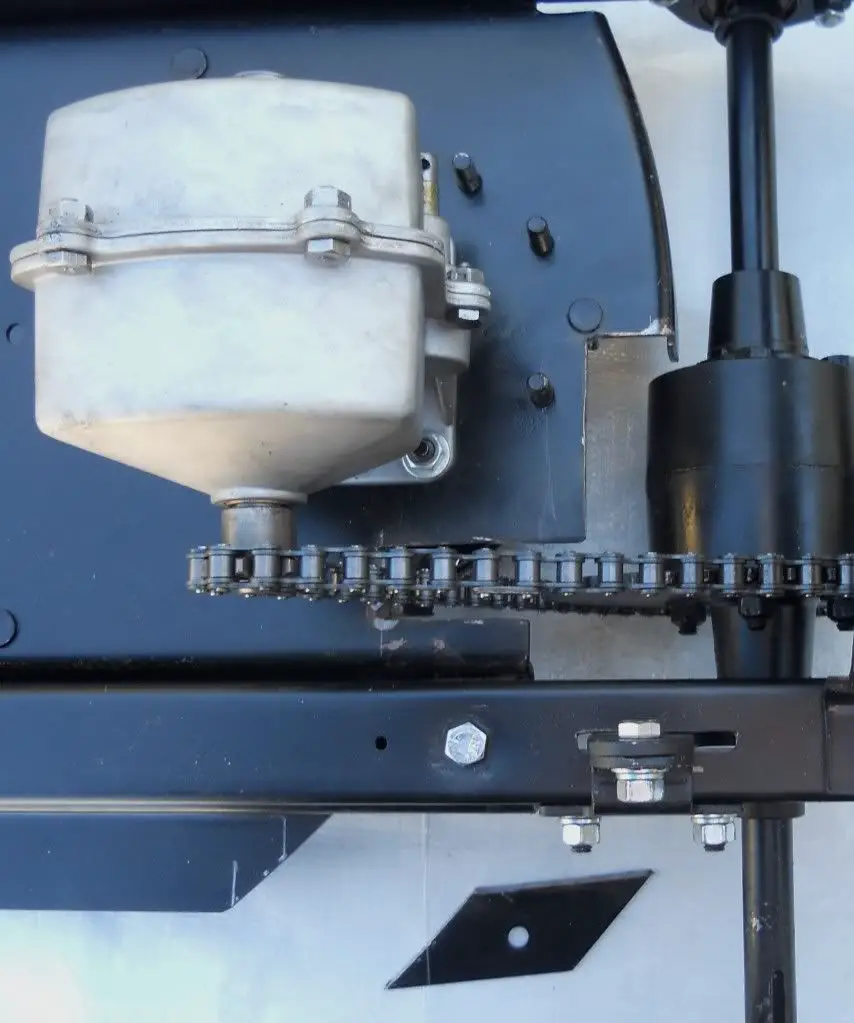

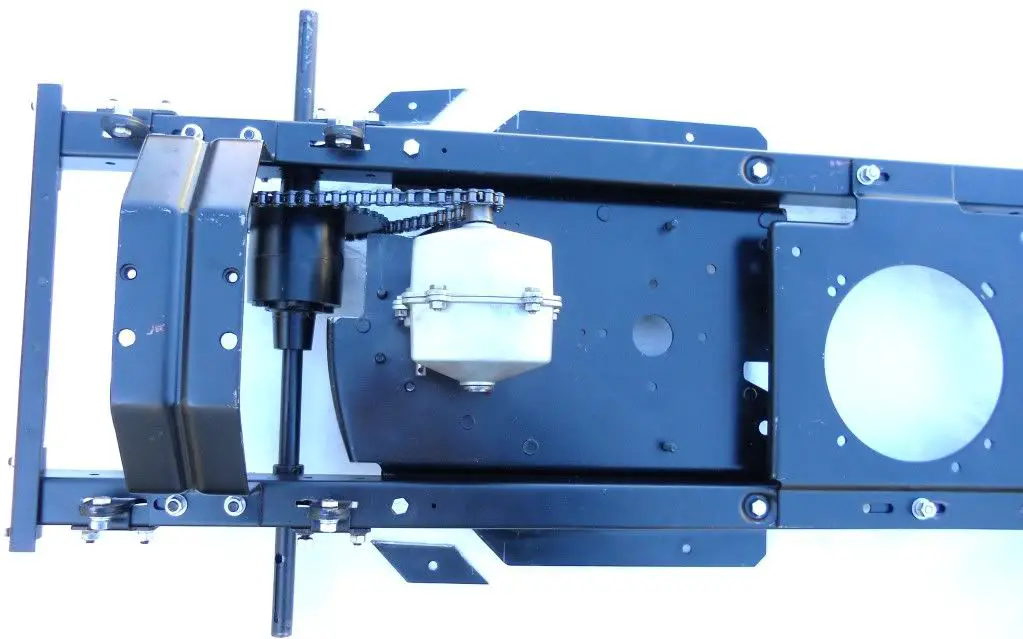

It uses a vertical shaft 5hp B&S motor with belt primary going to the pulley of the gearbox. The gearbox is just a forward/reverse. It's chained to the rear axle. Already removed that stuff for renovation.

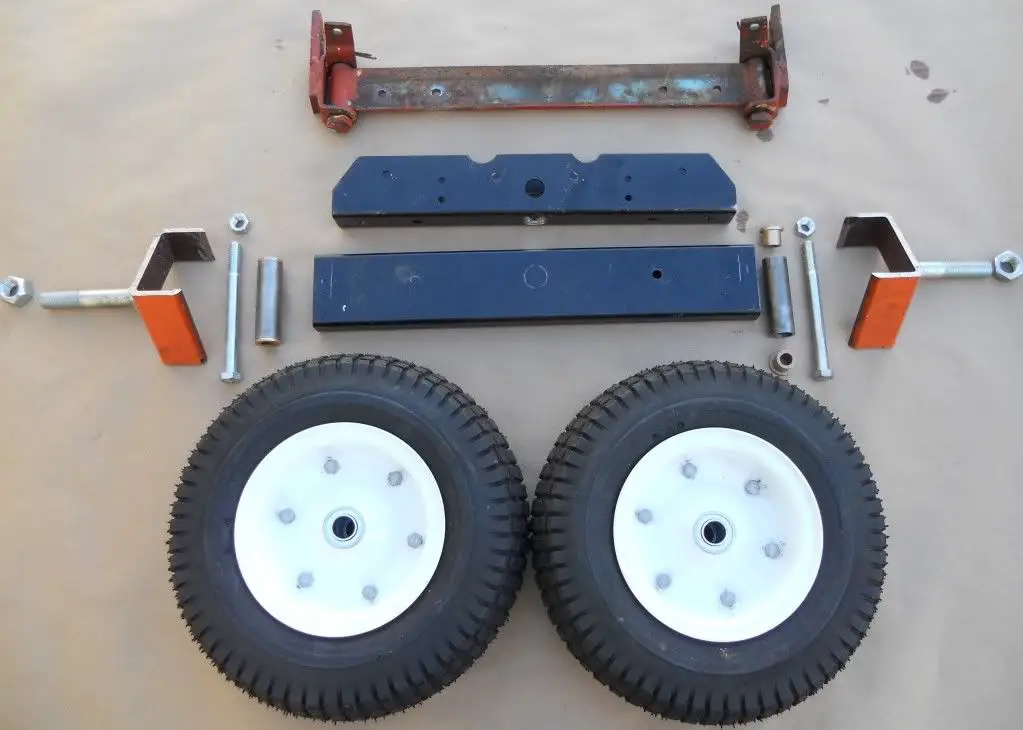

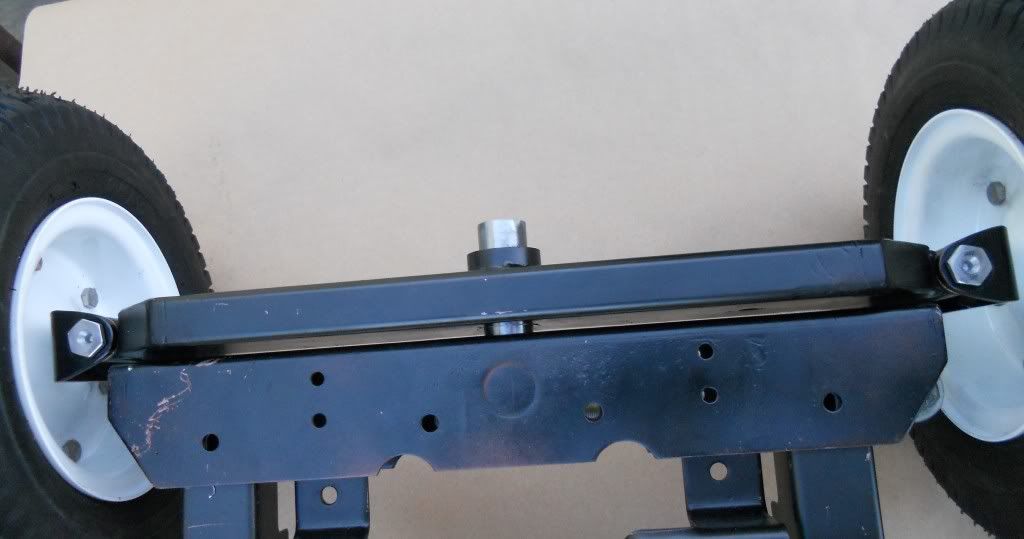

I replaced the solid axle with a differential I had laying around. Now it turns without scuffing the rear tires. Had a set of go-kart tires We're using.

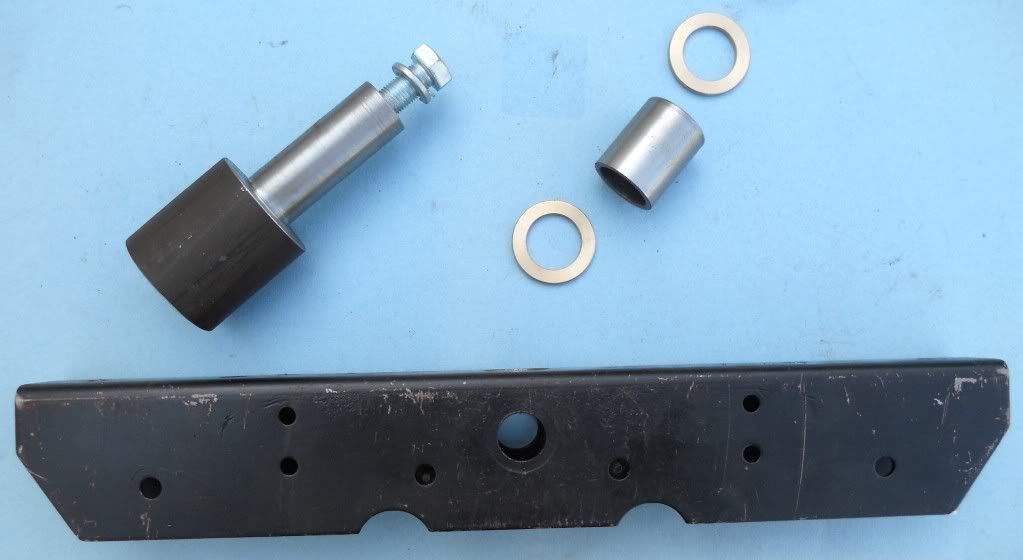

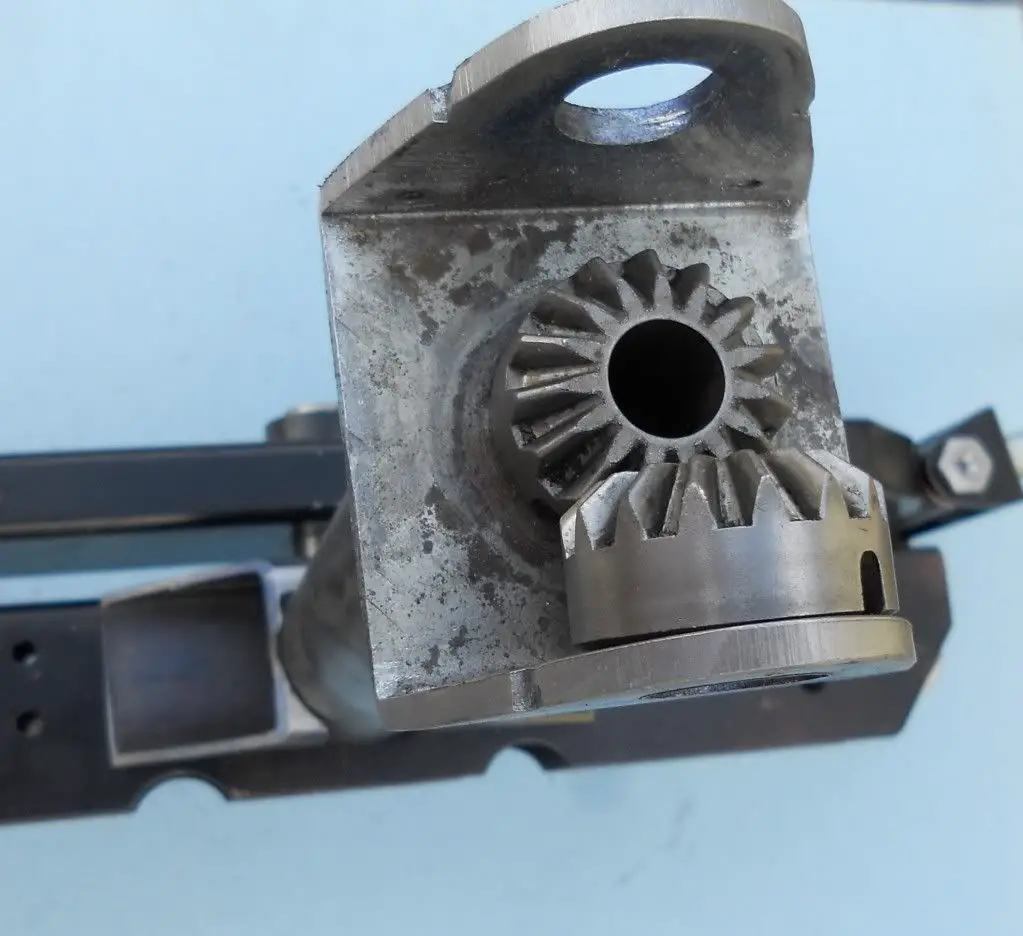

Here's some goodies that will be added, including a steering wheel instead of the tiller, a couple of bevel gears to make the steering shafts, a cool old Hurst shifter, a Max Torque clutch, some better tie rod ends and rear axle ball bearings to replace the bushings

That's what I have so far. Need to shorten the wheelbase about 3'', figure out the overall drive ratios for the speed we want, make the steering and supports, replace the front axle with a walking beam for a little flexibility and get new front wheels. Then we can start thinking about making the body. Fun project that will take a while. Anybody else out there making four wheel stuff?