Ok folks I am getting ready to test out some Ultra High Density Bendix clutch material for the china girls as clutch pucks.

This is rigid ferrous impregnated material that produces very little dust.

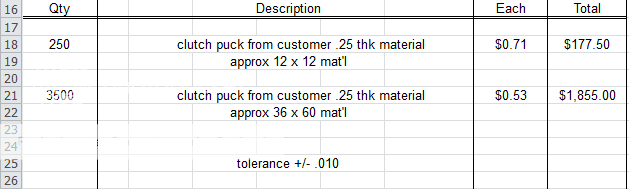

The material is very expensive and if I make these available to everyone I will have to get them cut out on a waterjet which is also expensive.

The upside is that you can get a clutch puck that fits the cut outs on the clutch with little to no fitting involved and a greater degree of performance and life from the pucks themselves.

I saw another post that had round pucks out of a similar material that were selling for $25 per set which I thought a little high.

I am researching this to see if you all think these would be something worth pursuing and if I can cover the material and machining costs and still make a small profit.

What I need to know:

The Poll allows you to answer both questions.

Thanks

Mark

This is rigid ferrous impregnated material that produces very little dust.

The material is very expensive and if I make these available to everyone I will have to get them cut out on a waterjet which is also expensive.

The upside is that you can get a clutch puck that fits the cut outs on the clutch with little to no fitting involved and a greater degree of performance and life from the pucks themselves.

I saw another post that had round pucks out of a similar material that were selling for $25 per set which I thought a little high.

I am researching this to see if you all think these would be something worth pursuing and if I can cover the material and machining costs and still make a small profit.

What I need to know:

- What price range do you think fair for an alternative to the OEM sets ($6.50 per set of 15)?

- Do you think this is an item that is needed that you would try?

The Poll allows you to answer both questions.

Thanks

Mark

Last edited: