One of the most desirable accessories for a vintage bike is one of the old ooga horns mounted on the handlebars. They have a great look and an obnoxious sound. Some are quite loud. I own a modest selection of the small bicycle/scooter horns I've been collecting for a few years that I would like to share. These are not for sale, just for show.

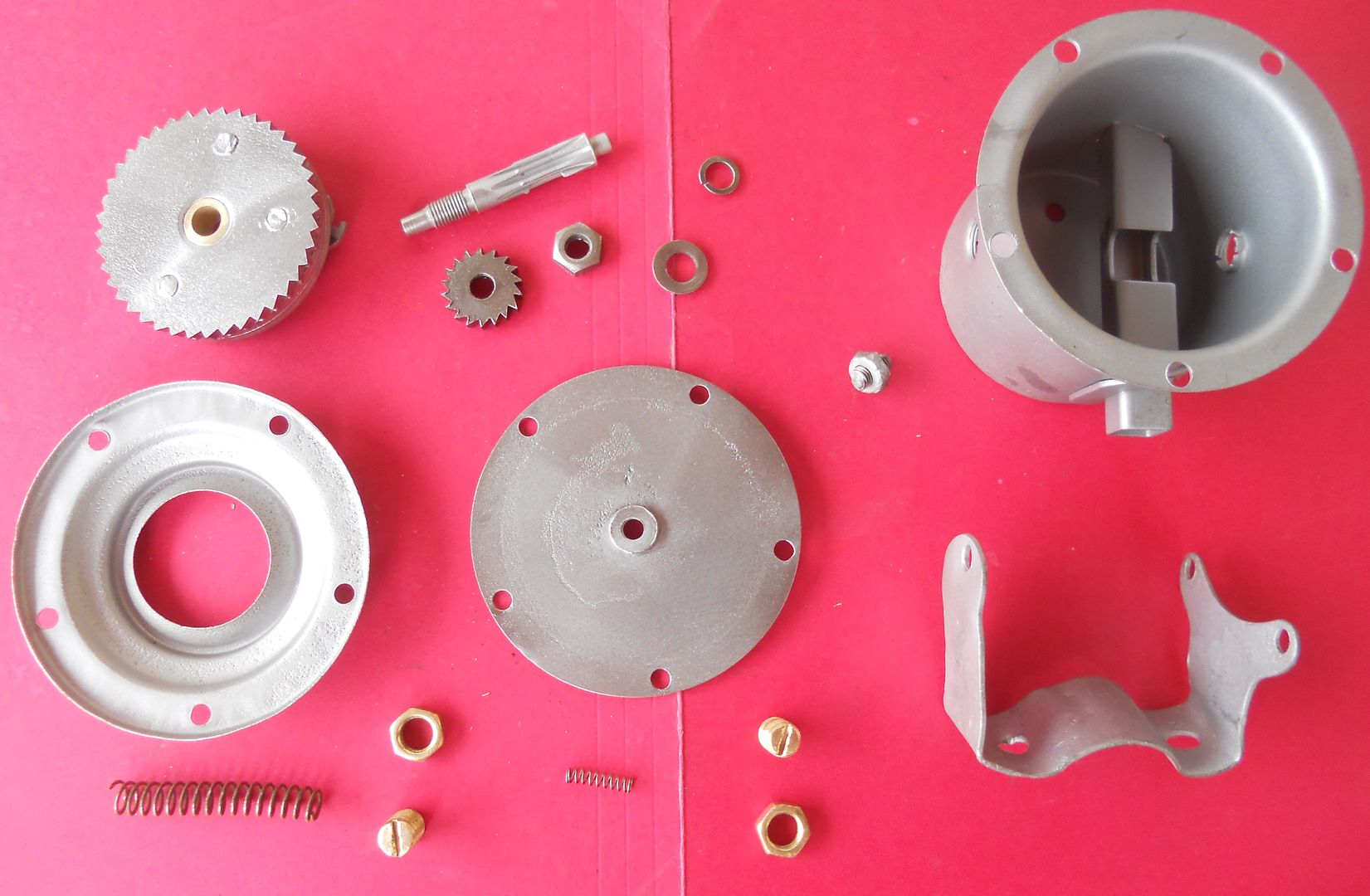

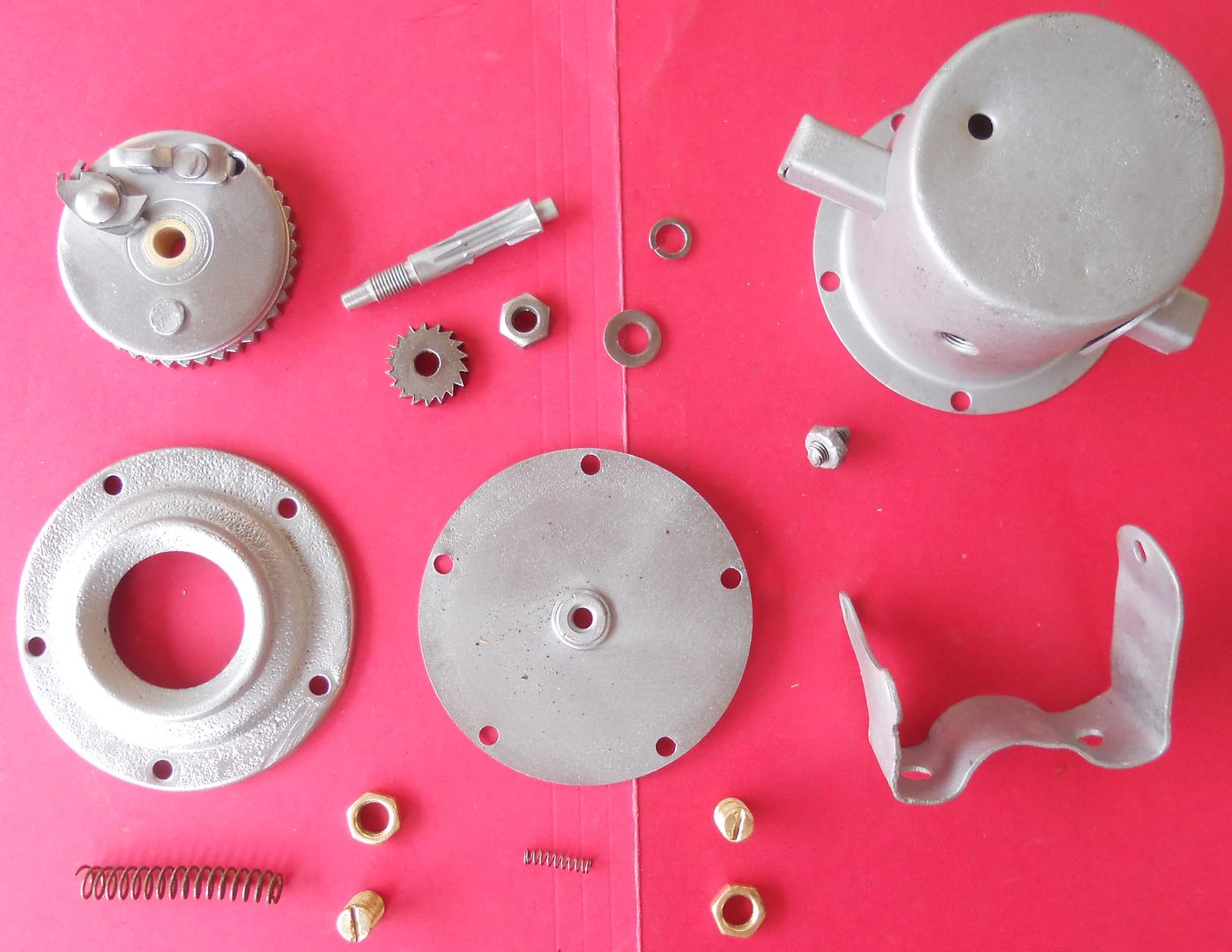

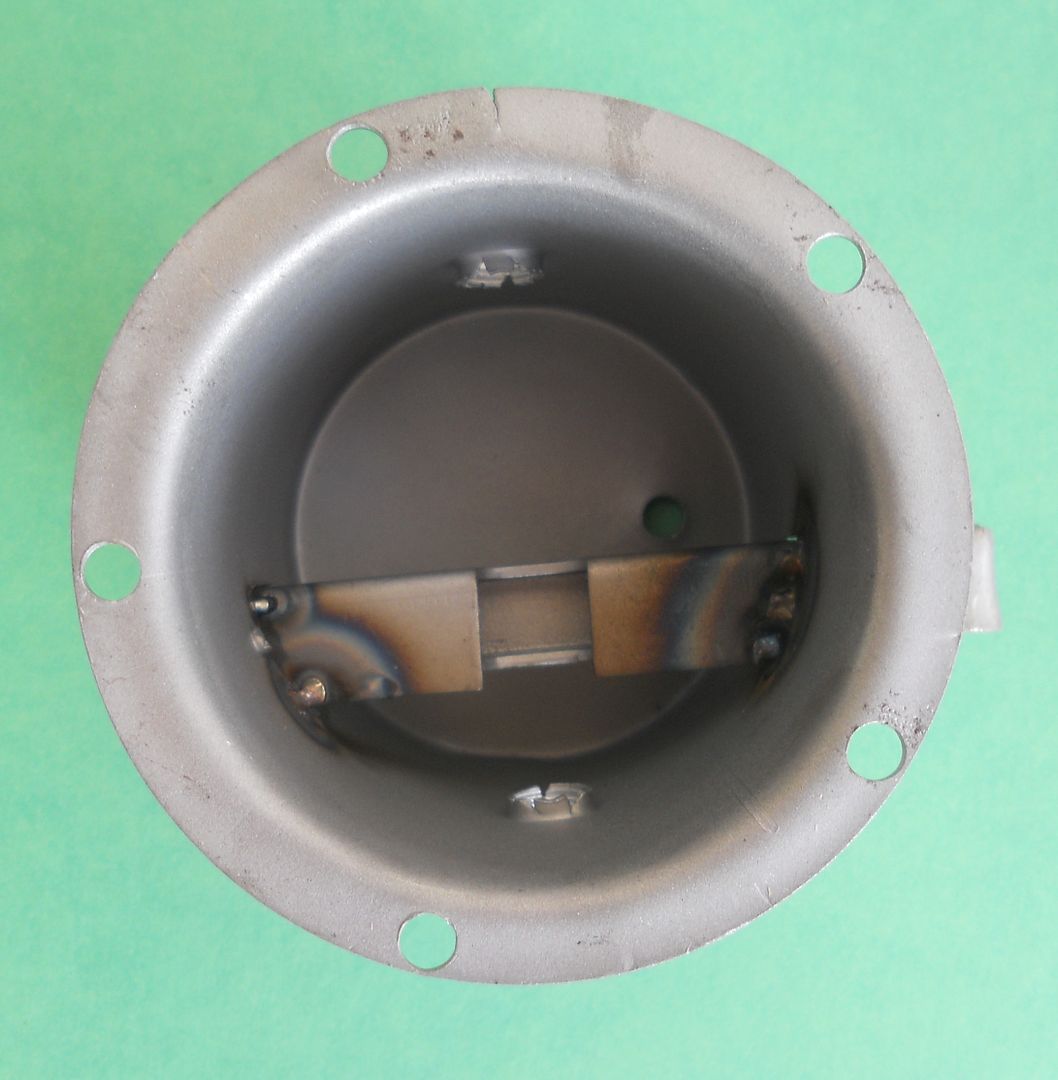

The top row is the most sought after. You've probably seen them on Whizzers, Cushmans and even Harleys, Indians, Hendersons, etc. They're made by EA Labs, Brooklyn, New York. They're also the most expensive. A few years ago you had to pay as much as $250 to $400 for one of these. Now that people realize they're fairly common, you can find them for under $100 on ebay and swap meets. The toothed flywheel inside sets them apart from the simple quack-quack horns, as they have more of an ooga sound but higher pitched than the larger automobile versions.

The cheaper made style have a segmented gear inside that reciprocates, activated by a plunger or lever and sounding like a duck. Still, some are pretty loud. They can be found for around the same price or less than the EA horns.

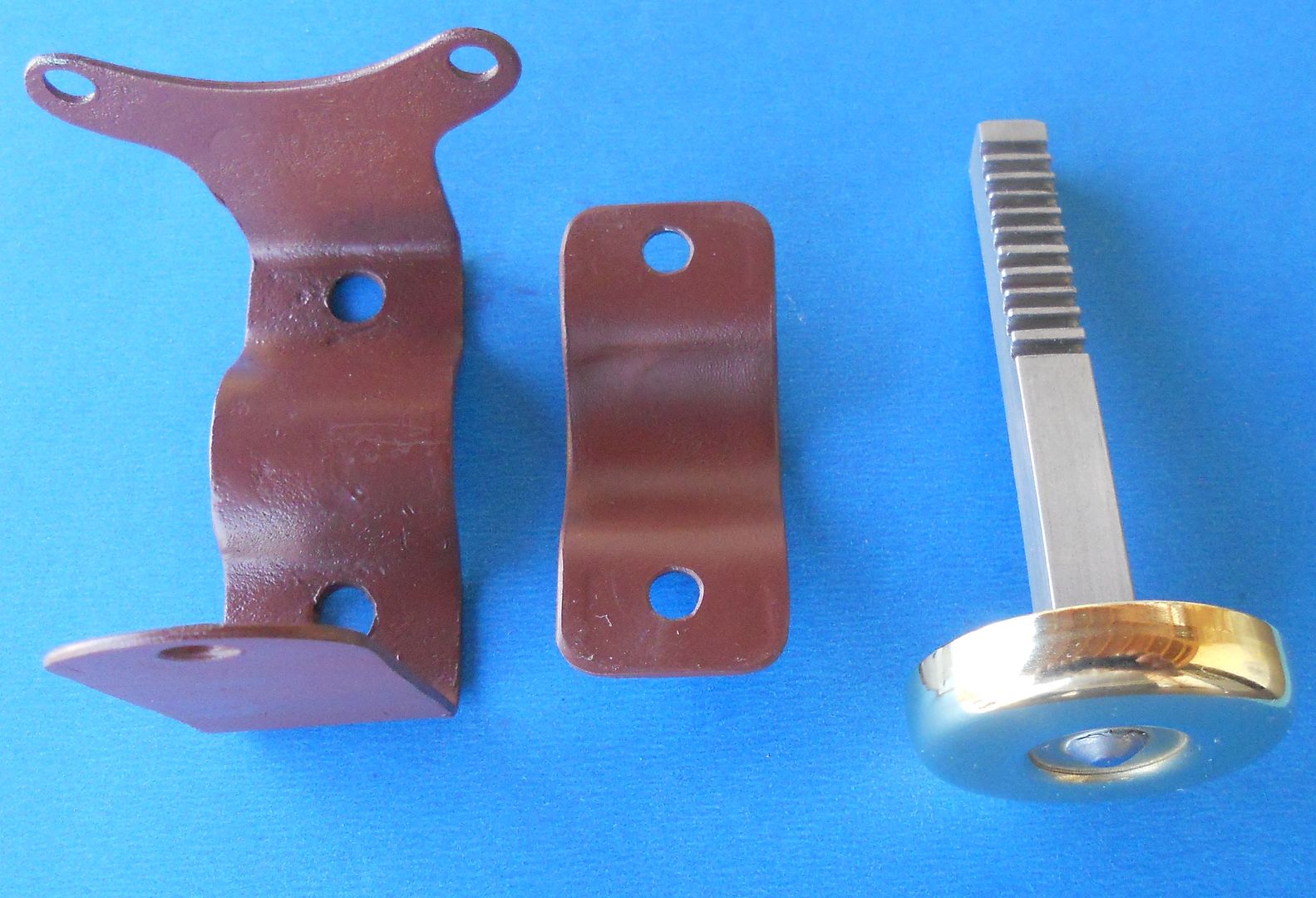

The White one in the photo that looks like a spiral horn is actually built like a bicycle pump with a plunger and a leather cup that pushes air through a diaphragm and really honks. Another desirable model found for around $100 on ebay.

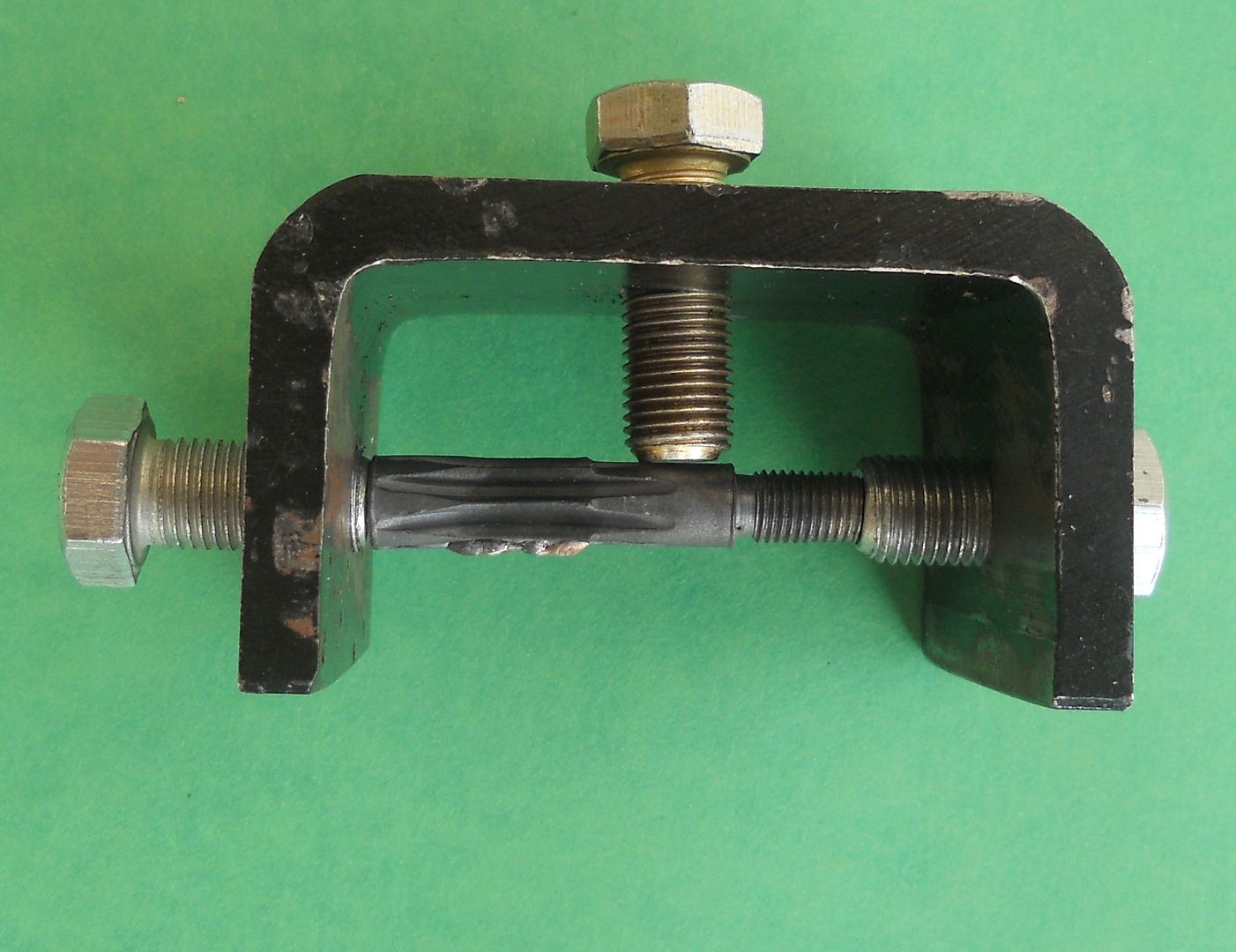

There's quite a lot going on inside, with a rack and pinion spinning a flywheel that rubs against an adjusting bolt in the middle of the diaphragm, and then ratcheting back up to be pushed again. The flywheel axle is supported at each end in adjustable brass cups. A strong spring under the plunger resets it.

The air activated horn also has a spring that pushes the cup back up.

These horns have been used since the 1800's and manufactured well into the 40's and 50's. A functional and great looking addition to any motorized bike, no matter what style.

Hope you enjoyed my post. I also have a collection of the larger motorcycle and automobile mechanical ooga horns. Let me know if you would like to see photos of them.

The top row is the most sought after. You've probably seen them on Whizzers, Cushmans and even Harleys, Indians, Hendersons, etc. They're made by EA Labs, Brooklyn, New York. They're also the most expensive. A few years ago you had to pay as much as $250 to $400 for one of these. Now that people realize they're fairly common, you can find them for under $100 on ebay and swap meets. The toothed flywheel inside sets them apart from the simple quack-quack horns, as they have more of an ooga sound but higher pitched than the larger automobile versions.

The cheaper made style have a segmented gear inside that reciprocates, activated by a plunger or lever and sounding like a duck. Still, some are pretty loud. They can be found for around the same price or less than the EA horns.

The White one in the photo that looks like a spiral horn is actually built like a bicycle pump with a plunger and a leather cup that pushes air through a diaphragm and really honks. Another desirable model found for around $100 on ebay.

There's quite a lot going on inside, with a rack and pinion spinning a flywheel that rubs against an adjusting bolt in the middle of the diaphragm, and then ratcheting back up to be pushed again. The flywheel axle is supported at each end in adjustable brass cups. A strong spring under the plunger resets it.

The air activated horn also has a spring that pushes the cup back up.

These horns have been used since the 1800's and manufactured well into the 40's and 50's. A functional and great looking addition to any motorized bike, no matter what style.

Hope you enjoyed my post. I also have a collection of the larger motorcycle and automobile mechanical ooga horns. Let me know if you would like to see photos of them.

Last edited: