Did that get your attention? Not as scary as it sounds - no close encounter of the road kind. On my last ride, I noticed a slight rattling or buzzing noise. I had just got into town about seven miles from home. I did a pretty good roadside check of motor mounts, engine components, anything that could be rattling loose. Couldn't find a problem, and I was hoping that my motor wasn't making a death rattle. When it was time to go home, I ran the motor as usual. Same noise - no better - no worse.

Back home a with a thorough scrutiny I spotted a sneaky little crack all the way through the rear brake mount between the seat stays. I was glad that my motor wasn't causing the noise, but a cracked frame isn't really GREAT news. The stress and vibration of the 2-cycle might have hastened the metal failure. But the motor mounts that I made by brazing pieces of iron plumbing pipe together are doing fine after a couple thousand miles. The frame is a 1973 Continental and it looked pretty beat up when I got it, so maybe there was a weak spot to begin with.

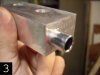

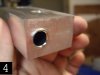

In the pic below the motor and brake caliper is removed and I've stripped down to bare metal for the welding. My neighbor welded it for me and it looks sturdy now. Since it's all apart, I'm making a better motor mount and will have to repaint the back end. I'll try to take some pics of the interesting parts as I go.

Back home a with a thorough scrutiny I spotted a sneaky little crack all the way through the rear brake mount between the seat stays. I was glad that my motor wasn't causing the noise, but a cracked frame isn't really GREAT news. The stress and vibration of the 2-cycle might have hastened the metal failure. But the motor mounts that I made by brazing pieces of iron plumbing pipe together are doing fine after a couple thousand miles. The frame is a 1973 Continental and it looked pretty beat up when I got it, so maybe there was a weak spot to begin with.

In the pic below the motor and brake caliper is removed and I've stripped down to bare metal for the welding. My neighbor welded it for me and it looks sturdy now. Since it's all apart, I'm making a better motor mount and will have to repaint the back end. I'll try to take some pics of the interesting parts as I go.

Attachments

-

83.1 KB Views: 321

Last edited: