well just thought of an easyer way ...

instead of building that differential and having to build the rest around the big thing ....

i could just make the flanges that will hold the wheels on via hub adapter, free wheel!

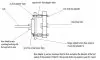

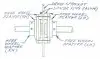

still need bmx free wheels though. just need to weld a steel flange drilled to acsept the manic mechanic hub adapter on the outside of the free wheel sprocket, then bolt the free wheel sprocket to the axle end, and the wheel to the free wheel via hub adapter .

with this setup you could use whatever style or size tire you want and move the wheel in and out just by changing the length of the spacers and bolts to accomodate a wider tire. the hub adapter is just a thick aluminum disk drilled to fit on the hub and drilled to match the sprocket bolt patern, it uses aluminum spacers and ss bolts to mount to the flange.

each wheel would drive foward but the outside one during a turn would free wheel

instead of building that differential and having to build the rest around the big thing ....

i could just make the flanges that will hold the wheels on via hub adapter, free wheel!

still need bmx free wheels though. just need to weld a steel flange drilled to acsept the manic mechanic hub adapter on the outside of the free wheel sprocket, then bolt the free wheel sprocket to the axle end, and the wheel to the free wheel via hub adapter .

with this setup you could use whatever style or size tire you want and move the wheel in and out just by changing the length of the spacers and bolts to accomodate a wider tire. the hub adapter is just a thick aluminum disk drilled to fit on the hub and drilled to match the sprocket bolt patern, it uses aluminum spacers and ss bolts to mount to the flange.

each wheel would drive foward but the outside one during a turn would free wheel

Attachments

-

53.7 KB Views: 211

-

59.4 KB Views: 177

Last edited: