Hey all,

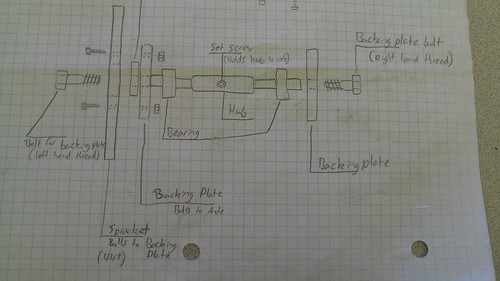

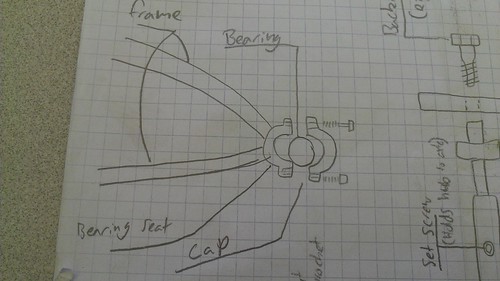

Been working on this project for a few weeks in shop class. I have til June to get all the major metal work done, so well see how it goes. I will be using an 8hp Briggs with a V belt go-kart style clutch and a #41 chain secondary... I'll also be machining my own pulleys because as long as i have access to the equipment I might as well take advantage of it, right? Well, anyhow, this is where I'm at so far. The frame is 10" longer, and I'll be making a drop loop to fit the big ol' mill in there. It will be 15" from the straight tube to the bottom of the loop. Not sure what kind of mount I want to do for the final drive... I'm thinking of making something similar to the ones that clamp around the rear hub, or maybe getting a Whizzer wheel (there's a dealer in town that might trade for some pinstriping). I'll cross that bridge when i get there though....

Thanks for the look!! Comments and criticism are much appreciated!!

IMAG1431 by ShortyLaVen, on Flickr

IMAG1488.jpg by ShortyLaVen, on Flickr

Been working on this project for a few weeks in shop class. I have til June to get all the major metal work done, so well see how it goes. I will be using an 8hp Briggs with a V belt go-kart style clutch and a #41 chain secondary... I'll also be machining my own pulleys because as long as i have access to the equipment I might as well take advantage of it, right? Well, anyhow, this is where I'm at so far. The frame is 10" longer, and I'll be making a drop loop to fit the big ol' mill in there. It will be 15" from the straight tube to the bottom of the loop. Not sure what kind of mount I want to do for the final drive... I'm thinking of making something similar to the ones that clamp around the rear hub, or maybe getting a Whizzer wheel (there's a dealer in town that might trade for some pinstriping). I'll cross that bridge when i get there though....

Thanks for the look!! Comments and criticism are much appreciated!!

IMAG1431 by ShortyLaVen, on Flickr

IMAG1488.jpg by ShortyLaVen, on Flickr