so i'm pretty much broke and built this thing in my garage out of scrap and junk that i either had lying around or salvaged where i could.

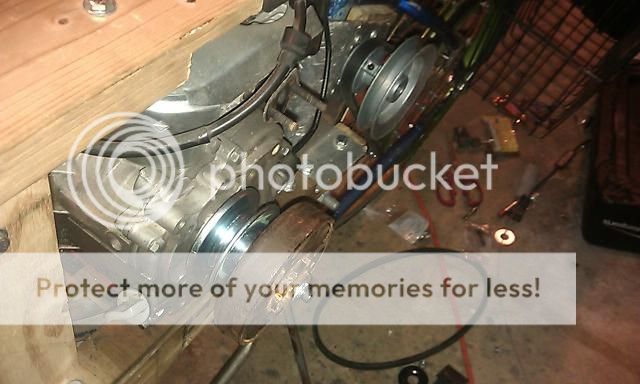

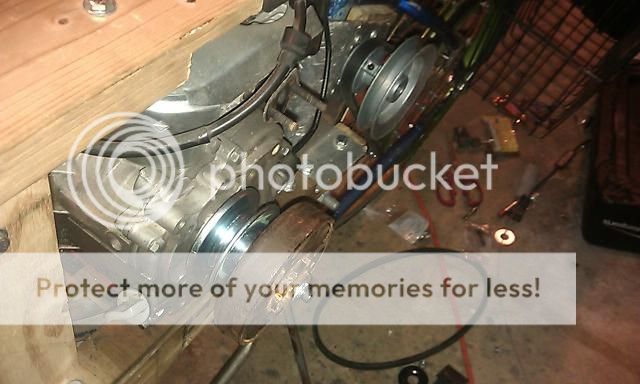

To start, i had a hawthorne stepthrough bike. I used lumber to build the engine mount and top tube. A few of the parts i took from a doodlebug mini bike i had sitting around. The engine is a 97 cc lifan. The rear sheave is a kids bike rim. Most of the pulleys and bearings were pulled from a do-it-yourself bandsaw kit. The jackshaft mount was made from an aluminum sign i cut up and bent. The clutch came from the minibike as well. I ground down the sprocket that was attached to it. I took a 1" bore pulley and slipped it over the clutch. If the set screws slip when running the bike, i'll have a friend weld the pulley to the clutch. I'm trying to avoid that however, as I've made this entire bike with no welds. here it is. let me know what you think

To start, i had a hawthorne stepthrough bike. I used lumber to build the engine mount and top tube. A few of the parts i took from a doodlebug mini bike i had sitting around. The engine is a 97 cc lifan. The rear sheave is a kids bike rim. Most of the pulleys and bearings were pulled from a do-it-yourself bandsaw kit. The jackshaft mount was made from an aluminum sign i cut up and bent. The clutch came from the minibike as well. I ground down the sprocket that was attached to it. I took a 1" bore pulley and slipped it over the clutch. If the set screws slip when running the bike, i'll have a friend weld the pulley to the clutch. I'm trying to avoid that however, as I've made this entire bike with no welds. here it is. let me know what you think

?? whats that?

?? whats that?