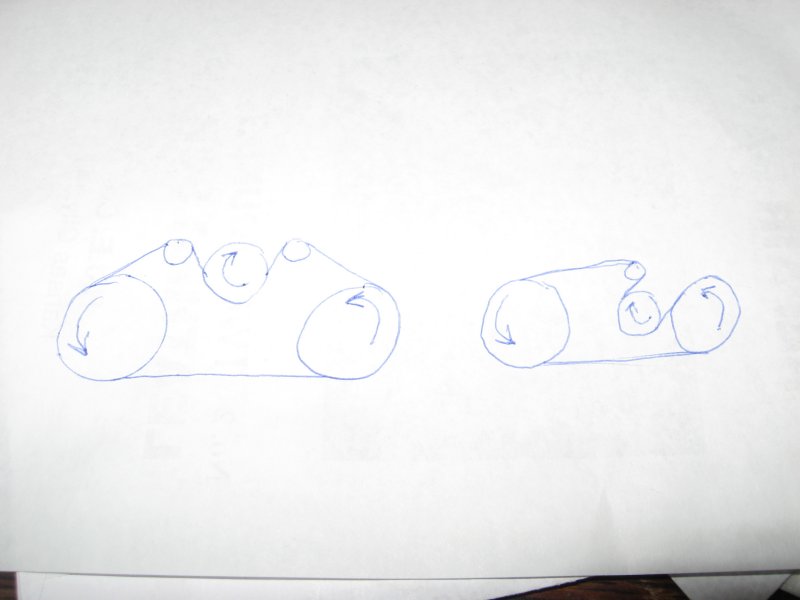

Nope not a "Rube Goldberg" setup as you say, it is the only way to reverse the rotation so you can power it from the left side of the bike with the engine output on the right and the engine running in the wrong direction. The other two ways is to turn the engine around and have it as not pleasing to look at or build a two gear gearbox to reverse the motor rotation before going through a jack shaft.I thought dracothered was suggesting the power flow was from the engine pulley-jackshaft-drive pulley on the other side of the seatpost-sheave or chain to the rear wheel. With the engine output shaft on the right side, this would make the bike go backwards.

If the plan is to drive through an idler pulley off the back of the belt it would work, but then you'd have a pulley spinning for no other purpose than to route the belt back to the engine....seems like a "Rube Goldberg" set-up to me.

In frame Predator fricton drive build

- Thread starter wayne z

- Start date

you could do an idler set up with a chain like that. Then if you have a multispeed bike and if you feel like being adventurous, you could then run a chain from the js to the bb outfitted with a 5/8 shaft and a sbp freewheel and freewheel hub so you could keep your peddles.What if the belt wrapped further around the idler (Of course then it wouldn't be an idler pulley) would it have enough grab then?

Oh, wait, that's what I did

http://motorbicycling.com/showthread.php?t=40383&page=2

although some people think I'm crazy...

Last edited:

If you look at the typical "Shifter" set up, you have a belt drive to a pulley, runs through a bearing(1), to a sprocket and chain to another sprocket on a jackshaft with (2) bearings, to another chain.If the plan is to drive through an idler pulley off the back of the belt it would work, but then you'd have a pulley spinning for no other purpose than to route the belt back to the engine....seems like a "Rube Goldberg" set-up to me.

So this eliminates a bearing, has one chain and eliminates a chain and a belt, and it's "Rube Goldberg"? Seems to me like a way to get the engine into a smaller frame, and end up with a shifter setup with fewer parts.

Last edited:

I just love "out the box" thinking and implementing. Kudos to you my friend :~)you could do an idler set up with a chain like that. Then if you have a multispeed bike and if you feel like being adventurous, you could then run a chain from the js to the bb outfitted with a 5/8 shaft and a sbp freewheel and freewheel hub so you could keep your peddles.

Oh, wait, that's what I did

http://motorbicycling.com/showthread.php?t=40383&page=2

although some people think I'm crazy...

I "like" this post :~)If you look at the typical "Shifter" set up, you have a belt drive to a pulley, runs through a bearing(1), to a sprocket and chain to another sprocket on a jackshaft with (2) bearings, to another chain.

So this eliminates a bearing, has one chain and eliminates a chain and a belt, and it's "Rube Goldberg"? Seems to me like a way to get the engine into a smaller frame, and end up with a shifter setup with fewer parts.

That is crazy looking for sure but I love it.you could do an idler set up with a chain like that. Then if you have a multispeed bike and if you feel like being adventurous, you could then run a chain from the js to the bb outfitted with a 5/8 shaft and a sbp freewheel and freewheel hub so you could keep your peddles.

Oh, wait, that's what I did

http://motorbicycling.com/showthread.php?t=40383&page=2

although some people think I'm crazy...

I don't think anyone got upset LOL everybody has opinions and the right to voice them and they shouldn't always be the same.Ok, my apologies to all. I didn't mean to upset anyone. Give it a go and tell us how it works.

Nope not upset in the least bit...I don't think anyone got upset LOL everybody has opinions and the right to voice them and they shouldn't always be the same.

Simplicity is often the most elegant. The EZM trans ran against conventional thinking when Quenton put the clutch on the opposite end of the drive, removing the heaviest piece from the end of the crankshaft and reducing the stresses on the engine.

Wayne took an engine and fit it into the frame in a way that made for a easier fit, and made it work with a series of different systems using a friction drive. These motors fit the frame triangle so much better with the drive off the right side. I've had conversation with David Staton about building a gearbox to accomplish this reversal for a shifter application. However, the simplest system would be as drawn with only the addition of a couple idlers to make it happen.

Wayne took an engine and fit it into the frame in a way that made for a easier fit, and made it work with a series of different systems using a friction drive. These motors fit the frame triangle so much better with the drive off the right side. I've had conversation with David Staton about building a gearbox to accomplish this reversal for a shifter application. However, the simplest system would be as drawn with only the addition of a couple idlers to make it happen.

What do you mean by "tin removal"?... consider using an auto clutch, kills a roll start and the tin removal, ...

Lookin good Wayne 190+mpg your catching up to mine (202mpg) I love the fact yours is in frame and 2 speed from the sounds of it you can ride all day with out issue. My FD's are 2 smokers and must cool down after 30 miles or so. Where is the flower?? Ive seen one on most your other builds did I just miss it? Once agian its looking real good, Rick

Well, that sure is an interesting chain run!

I don't know that I would call it Rube Goldberg, either...

I'm thinking dual counter rotating props are used in boats and aircraft.

There must be a very valid reason for going through the mechanics of the required drive system, even though it is more complicated.

Fun stuff!

rc

I don't know that I would call it Rube Goldberg, either...

I'm thinking dual counter rotating props are used in boats and aircraft.

There must be a very valid reason for going through the mechanics of the required drive system, even though it is more complicated.

Fun stuff!

rc

What happens to them after 30 miles? What are you using?

Lookin good Wayne 190+mpg your catching up to mine (202mpg) I love the fact yours is in frame and 2 speed from the sounds of it you can ride all day with out issue. My FD's are 2 smokers and must cool down after 30 miles or so. Where is the flower?? Ive seen one on most your other builds did I just miss it? Once agian its looking real good, Rick

Hi all there is another way. Have a new custom ground camshaft for reverse rotation. it is simple just a mirror the old one, any good cam grinder can weld up the old cam and regrind it. this has been done for years In some race boats an twin engine air planes. engine timeing would need to be addressed too. a new keyway cut in the flywheel would solve this.

there was a reverse rotation camshaft for chevy corvairs engine so thay could be installed in vw.

you would need to rope pull or bump start the engine.

Don P

there was a reverse rotation camshaft for chevy corvairs engine so thay could be installed in vw.

you would need to rope pull or bump start the engine.

Don P

Last edited:

If I'm not mistaken, the compression release is a mechanism in the camshaft's exhaust lobe (on the heel). Still possible, but as easy as you might think. Retaining the compression release is probably possible as well, but would require some skillfull machine work.

MHF

MHF

motorhedfred you are right. but i repeat " any good cam grinder" will index the cam befor they start and will duplicate the ramp an compression release.

you can ask to add lift and duration too.

this is just another way of doing it. and would probably cost more than the engine cost.

Don P

you can ask to add lift and duration too.

this is just another way of doing it. and would probably cost more than the engine cost.

Don P

Ok, you win, good cam grinders cam accomplish anything. I'm tired of youtube and forum pi$$ing contests. Everybody's an expert and knows more than me...got it.

MHF

MHF