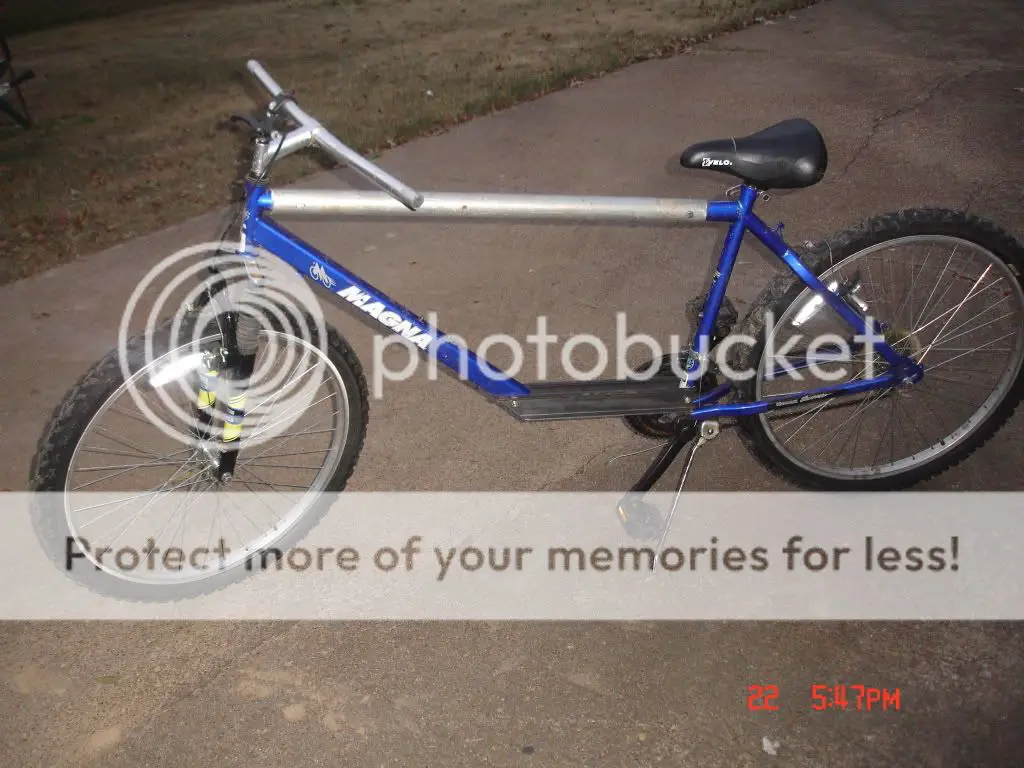

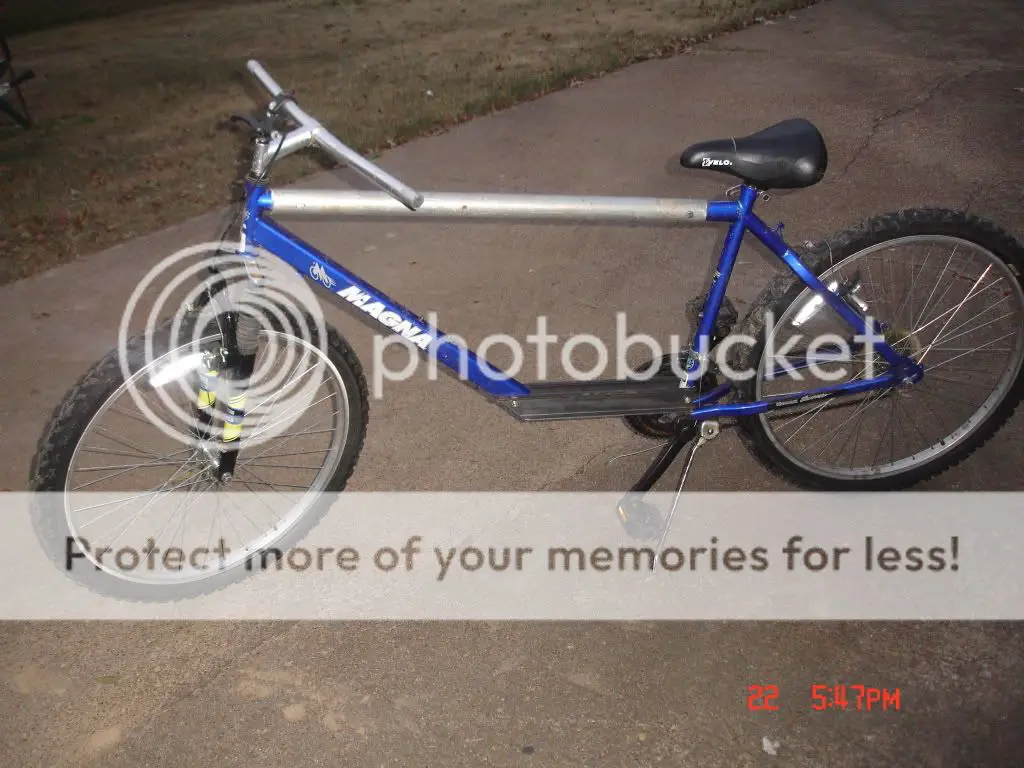

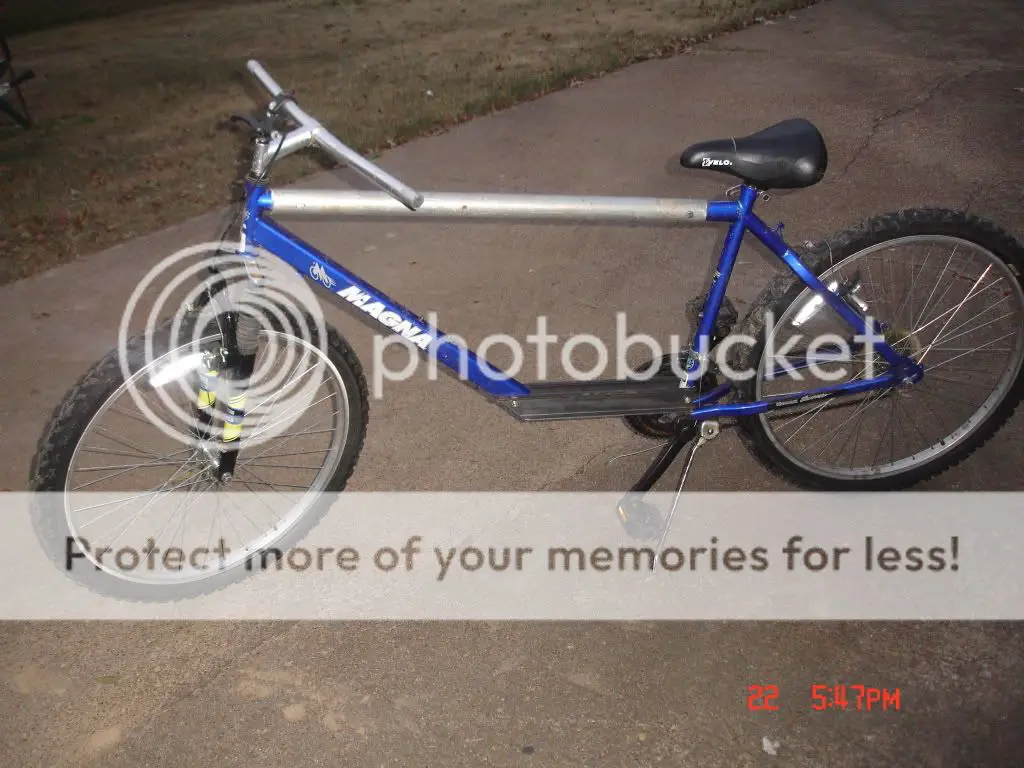

Just finished lengthening frame 14''. Also found a chain-drive belt jackshaft of a Yazoo lawnmower. Hopefully, I will now have enough room for my 3.5 edger motor.

You have a coupon for a 6.5 HP motor? The best I can come up with is $129.99 w/15% off coupon $110.49. I've looked through my emails etc. but no item specific coupon for that motor.<snip>

Were you thinking of using a Chinese motor, a Briggs, or Honda ? Harbour Freight now has a motor on sale for $100 which could be used with a centruigul clutch. They are 6.5 hp limit 1 w/cupon. I've estimated the materials I would use would cost $500+ for my build.

No kidding...SCARY. Dude, please don't leave it like that...those bolts, especially the ones on the bottom brackets are going to shear off or pull out of frame. Weld that sucker if at all possible. If you insist on taking the risk and using bolts than at least use 3/8" bolts with large washers and locking nuts and by all means double up each location.Is that thing held together with bolts!!! Yikes.

While I know your intentions are good the project bike frame in the pics will never work. The first thing is that you cannot weld aluminum and steel together. Even if it was all aluminum the entire frame would have to be heat treated after welding or else the welds will fail. Welding dissimilar aluminum alloys is also problematic. Even a highly trained welder with the best equipment would not attempt to make this frame a reality.I haven't welded since high school.Mainly oxy/acet with a little arc. What is the prefered method of welding bike frames? I also will have to buy or rent welding equipment.

Thanks eDJ<snip>

You'll have to blow these images up to where they print out at 8 1/2 x 11 on your printer. These images are 50% of their actual size so I could upload them. With your ink printer's software should allow you to double their size for the print set up so they will print the 8 1/2 x 11 or however you wish to do it. (I don't know how skillful you are at doing this stuff)

If you need, get someone to help ya, and good luck at HF when you give them the cupon. If you catch them busy that would probably be a good time to have the cupon and cash in hand to go into the line.

While I know your intentions are good the project bike frame in the pics will never work. The first thing is that you cannot weld aluminum and steel together. Even if it was all aluminum the entire frame would have to be heat treated after welding or else the welds will fail. Welding dissimilar aluminum alloys is also problematic. Even a highly trained welder with the best equipment would not attempt to make this frame a reality.

But you can achieve what you wish perhaps by brazing although you will have to use steel, which is a better choice for the type of weight you are proposing to throw on there in the form of a motor, there is info on that method here: Braze Your Own Bicycle Frame.

Good luck and be safe, not sorry.