solid or rubber mount engine?

- Thread starter macattie88

- Start date

Both mounts are important but…Yep sorry the rear mount to the seat tube, this which was my point is the critical mount to be square and solid.

The front is more important to rigidity. The rear mount is a 1in long spacer slipped over long studs. The front mount is an integral part of the engine and has a shorter coupling. The down tube is the stiffest member on a bicycle frame. Much stiffer than the seat tube.

Bolt a piece of tubing to the rear mount and see how easy it is to rock forward and back. Try the same thing with the front mount. Much stiffer. That fact coupled with the stiffer frame tube makes the front mount the most important connection (in my opinion).

well we can agree to disagree, i think the rear mount is more critical as thats where the drive is comming from. sure you dont want the motor to turn from a loose front mount, seat tubes are generally thinner and fit in the semi circle provided. How many of us have the front sitting in the mount? i see alot of drilled frames and ubolts these void that theory well maybe not the ubolt.

The bike im useing now the v is slightly off so tried squaring the front and having the rear slightly off vibrated wildly so i squared the rear up, no vibration.

Just my personal opinion....may well be wrong

The bike im useing now the v is slightly off so tried squaring the front and having the rear slightly off vibrated wildly so i squared the rear up, no vibration.

Just my personal opinion....may well be wrong

True. The rear mount is more important for resisting the drive chain loads. I was talking about vibration resistance when referring to the front mount.well we can agree to disagree, i think the rear mount is more critical as thats where the drive is comming from. ...

Hey fellers,

Please address this point for me: it's been suggested that i "create?" additional support on both tubes below the motor mount tube brackets. i was said that one end, i forget which, is prone to start slipping down. what's the skinny? what would material would you all suggest to use for these backup brackets? i usually default to hose clamps and bailing wire; there must be a more effective way

thanks

Please address this point for me: it's been suggested that i "create?" additional support on both tubes below the motor mount tube brackets. i was said that one end, i forget which, is prone to start slipping down. what's the skinny? what would material would you all suggest to use for these backup brackets? i usually default to hose clamps and bailing wire; there must be a more effective way

thanks

Besides my custom front mount and stock rear mount, i use a MUFFLER STRAP to hold engine against frame and stop from twisting when accelerating.

I used HOSE CLAMPS on frame under my mounts when i first position my motor to hold it in position til i tighten up the mounts and bolts.

Chimney or muffler strap also comes in handy for extra suport.

I used HOSE CLAMPS on frame under my mounts when i first position my motor to hold it in position til i tighten up the mounts and bolts.

Chimney or muffler strap also comes in handy for extra suport.

Last edited:

muffler clamps; sounds like and effective "stop". thanks for all the good advice; i appreciate you takin time to respond.Besides my custom front mount and stock rear mount, i use a MUFFLER STRAP to hold engine against frame and stop from twisting when accelerating.

I used HOSE CLAMPS on frame under my mounts when i first position my motor to hold it in position til i tighten up the mounts and bolts.

Chimney or muffler strap also comes in handy for extra suport.

kevin

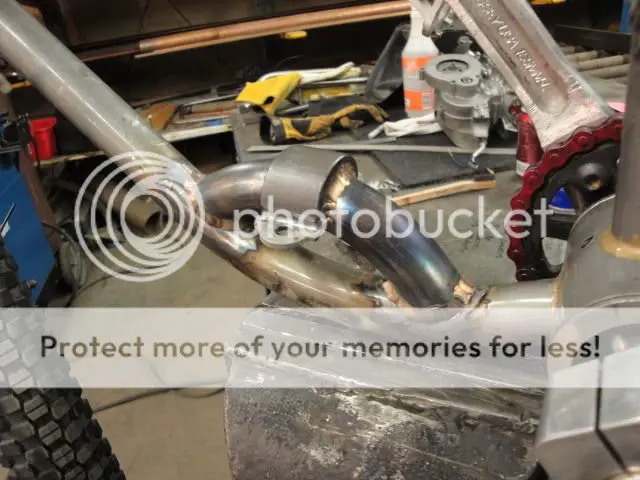

Personally I am running a solid mount with all stock hardware. A detail that I did see as I read through the posts is no comment of how effective the stock mount set up is without added hardware when it is installed exactly as intended. My frame geometry is tweaked to match the two concave mounting surfaces for 90% contact or better.

When the motor is nested into the crotch of the V it keys itself into place before studs even come into play. Any lateral twisting and axial twisting is inhibited by the two concave contact points working with each other. My studs are not so much holding the motor on as they are just keeping the relationship of the mounts in alignment with the frame so that the mounts do their job.

That being said, I did not want to use any media between the mount and the frame that would distort a good contacting fit. This is just my opinion, but I don't have broken studs or trouble with motor position.

When the motor is nested into the crotch of the V it keys itself into place before studs even come into play. Any lateral twisting and axial twisting is inhibited by the two concave contact points working with each other. My studs are not so much holding the motor on as they are just keeping the relationship of the mounts in alignment with the frame so that the mounts do their job.

That being said, I did not want to use any media between the mount and the frame that would distort a good contacting fit. This is just my opinion, but I don't have broken studs or trouble with motor position.

Attachments

-

205.9 KB Views: 255

Which is precisely the way they were intended to be mounted. k.i.p has done everything right. The better the contact area within the concave mounting points, the better off you'll be as far as vibration and fastener life. You can't argue with success.Personally I am running a solid mount with all stock hardware. A detail that I did see as I read through the posts is no comment of how effective the stock mount set up is without added hardware when it is installed exactly as intended. My frame geometry is tweaked to match the two concave mounting surfaces for 90% contact or better.

When the motor is nested into the crotch of the V it keys itself into place before studs even come into play. Any lateral twisting and axial twisting is inhibited by the two concave contact points working with each other. My studs are not so much holding the motor on as they are just keeping the relationship of the mounts in alignment with the frame so that the mounts do their job.

That being said, I did not want to use any media between the mount and the frame that would distort a good contacting fit. This is just my opinion, but I don't have broken studs or trouble with motor position.

Tom